Fortune progressing Canadian critical minerals project

TSX-listed Fortune Minerals has provided an update on ongoing work on the vertically integrated NICO cobalt/gold/bismuth/copper critical minerals project in Canada, with test work, engineering, an updated feasibility study, and permitting programs progressing.

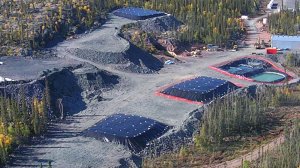

The NICO project comprises a planned mine and concentrator in the Northwest Territories and a hydrometallurgical processing facility in Lamont county, Alberta, where concentrates from the mine, along with other feed sources, will be processed into value-added products needed for the energy transition, new technologies, and defence.

Fortune has been awarded about C$17-million in non-dilutive contribution funding from the US Department of Defense (DoD), Natural Resources Canada (NRCan), and Alberta Innovates to help finance the work needed to bring the NICO project to a project finance and construction decision.

Development of the NICO project would provide a reliable North American supply of cobalt sulphate, gold doré, bismuth ingots, and copper precipitate, enhancing domestic supply chains for three metals identified on the Canadian and US government critical minerals lists, with a highly liquid and countercyclical gold co-product to mitigate metal price volatility.

Fortune retained Worley Canada to lead the engineering for an updated feasibility study, assessing the economics of the NICO project at current costs and commodity prices.

The previous study is now out of date, and several participants from that study are assisting with the update. Worley is also supporting Fortune with permitting for the brownfield site, where the company plans to construct its hydrometallurgical facility.

The feasibility study is being supported by funding from the US DoD and NRCan’s Global Partnerships Initiative (GPI). The updated study will incorporate several improvements identified by Fortune and Worley to deliver a more financially robust development.

Worley has also completed value enhancement studies, reviewed the company’s historical flotation test work and piloting data, and identified opportunities to use Jameson flotation cells to recover additional fine, 5- to 20-micron gold and bismuth particles from NICO deposit ores.

A carbon column is being designed into the secondary flotation circuit to capture the approximately 5% of gold that previously would have been dissolved and lost during bismuth and cobalt separation. Fortune is also exploring other options to reduce potential gold losses during the processing of high-grade, gold-rich ores.

Worley has realigned the NICO access road design to reduce construction costs and has completed the process flow diagrams, piping and instrumentation diagrams, and mass balance for the Northwest Territories concentrator.

As part of ongoing feasibility study improvements, Worley is updating concentrator and hydrometallurgical facility designs to advance the vertically integrated development.

For test work, material has been shipped to SGS for metallurgical testing and piloting. Phase 2 of the programme, consisting of crushing, grinding, and bulk and secondary flotation, was successfully completed in the third quarter of 2024, producing gold-bearing cobalt and bismuth concentrates for hydrometallurgical testing.

Phase 3 hydrometallurgical work is underway, with results exceeding the company’s expectations. Ferric chloride leaching of bismuth concentrate, followed by cementation and purification tests, achieved 97% bismuth recoveries, producing a cement grading up to 95% bismuth and averaging about 0.2% iron as the main impurity.

This data supports the bismuth circuit process design criteria, reducing leaching residence time by 66%, from three hours to one hour. These design improvements are expected to significantly reduce the size, capital, and operating costs for the bismuth circuit in the hydrometallurgical plant.

The results also indicate a 2% higher bismuth recovery than initially estimated for the bismuth leaching and cementation circuits.

Fortune has retained XPS Industry Relevant Solutions to conduct the smelting and refining aspects of the bismuth test work and complete the design of the bismuth pyrometallurgical circuit.

A preliminary pressure oxidation (POX) test on the cobalt concentrate was recently completed, with more comprehensive cobalt processing tests planned for Q1 2025. The cobalt test work will include optimization of sequential gypsum precipitation to validate the production of a gypsum by-product from autoclave effluent.

If successful, this by-product would provide a significant revenue boost to the hydrometallurgical facility and reduce waste disposal costs for process residues.

COLLABORATION

Fortune has a process collaboration agreement with Rio Tinto to investigate the feasibility of recovering additional cobalt and bismuth at the Alberta hydrometallurgical facility by processing precipitates produced from Kennecott smelter wastes in Utah.

The feasibility of processing Rio Tinto material at the Alberta facility has been confirmed, and additional work is planned by both companies to advance the collaboration.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation