From fibre to flow: How hose engineering impacts performance

In high-stakes industrial and processing environments where uptime is currency and reliability is non-negotiable, seemingly small decisions can have significant consequences. Take for instance, the choice between OEM and non-OEM hoses for peristaltic pumps.

At first glance, non-OEM hoses may appear to offer a cost-effective alternative. But in mining, chemical processing, and other heavy-duty sectors, this short-term saving often comes at the expense of long-term performance, safety, and profitability. Compared to choosing OEM hoses, like Verderflex, which isn’t just about quality; it’s a strategic investment in uptime, safety, and long-term profitability.

Why hose integrity matters

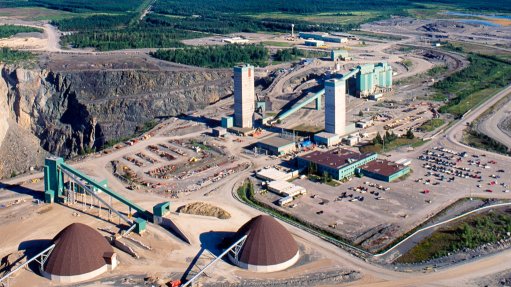

Peristaltic pumps are prized for their ability to handle abrasive slurries, corrosive chemicals, and viscous fluids with minimal maintenance. But their performance hinges on one critical component: the hose. When that hose fails - especially in remote or continuous operations - the ripple effects can be costly.

Non-OEM hoses often fall short of the precise specifications required for optimal pump performance. Inferior materials, inconsistent wall thickness, and poor reinforcement can lead to premature wear, reduced flow efficiency, and even catastrophic failure. In mining operations, where downtime can cost thousands per hour, a failed hose is more than an inconvenience - it’s a liability.

The Verderflex advantage: Engineered for endurance

Hose failure most often results from mechanical fatigue, due to the gradual loss of elasticity in the reinforcing fibre after millions of operational cycles. To maximise hose lifespan, it’s essential to optimise mechanical strength.

Verderflex hoses are designed with durability at their core. By incorporating up to three times more nylon reinforcing fibre, Verderflex distributes mechanical stress more evenly, significantly extending hose lifespan. This is especially critical in applications with high pulsation, pressure fluctuations, or abrasive media, common in mineral processing and slurry transfer.

Additionally, Verderflex hoses feature a textured outer surface that enhances lubricant retention and cooling through capillary action. This reduces friction, prevents overheating, and further prolongs operational life. The result? Fewer changeouts, less downtime, and lower total cost of ownership.

Designed for precision, built for performance

Every Verderflex hose is manufactured to exact standards, with consistent wall thickness and outer diameter along its entire length. This eliminates the need for post-production machining, preserving the hose’s structural integrity and ensuring a perfect fit every time.

To reduce the risk of installation errors - another common cause of premature failure - Verderflex embeds permanent, colour-coded identification tapes during vulcanisation. This makes it easy to match hose materials to specific chemical or temperature requirements, even in fast-paced maintenance environments.

Hose base material matters

Verderflex EPDM hoses are constructed from 100% EPDM, rather than using a thin liner over natural rubber. This homogeneous construction offers higher temperature resistance, eliminates weak points caused by rubber junctions, and provides greater chemical resistance. The result is a more robust hose with a longer, more reliable service lifespan.

Beyond the hose: Protecting your investment

Another crucial consideration is that using non-OEM hoses doesn’t just compromise performance; it can also void pump warranties and cut off access to expert technical support and servicing. That’s a risk few operations can afford.

More than 65 years of experience in professional pumping applications make Verder the pump manufacturer of choice for customers from many industries on all continents. Our commitment to quality extends beyond the product itself. We offer deep process understanding, technical expertise, market insights and tailored support to help clients optimise performance and reduce lifecycle costs. This is how we enable your progress.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation