Global pumps manufacturer brings training and expertise to SA

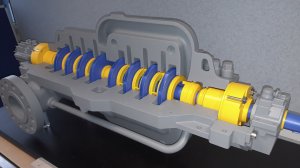

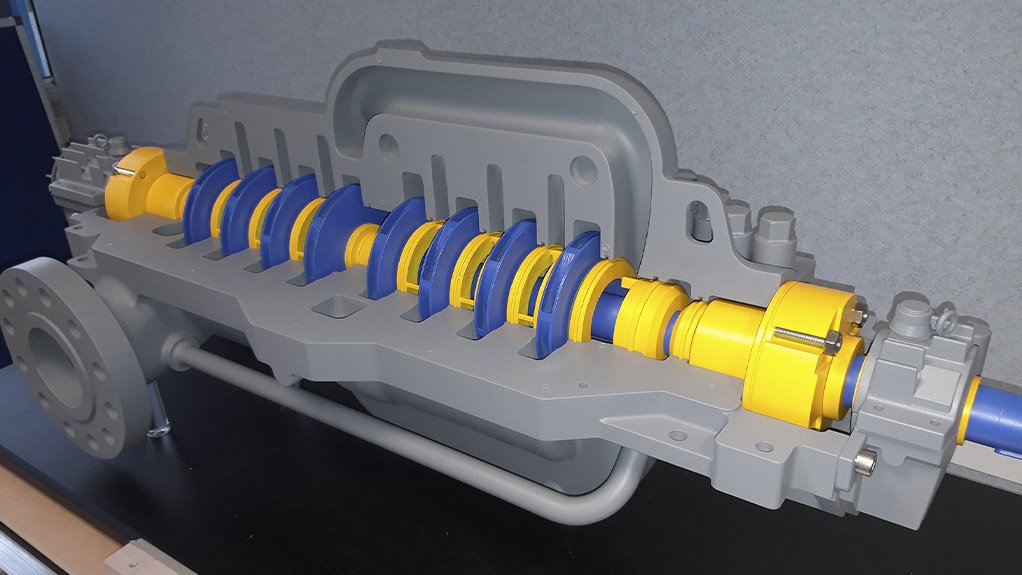

HANDS-ON TRAINING Training can involve using a cut-away model to help explain the function of the internal components and how they interact

Pump manufacturer and independent maintenance specialist Sulzer is investing in its South African operations to ensure that it is well positioned to cover the needs of the mining sector locally and in Southern Africa.

“Sulzer is continually investing in its personnel and facilities to enhance its service. The main focus for the pumps-related business is to deliver a comprehensive service through a local point of contact. This has been supported by the recent appointment of additional sales engineers dedicated to the gold and platinum mining sectors specifically,” states Sulzer sub-Saharan Africa sales head Robert Blignaut.

He emphasises that this investment and extensive knowledge of local conditions are vital to servicing local customers. The presence of Sulzer’s service centres in Welkom, in the Free State, as well as in Johannesburg, in Gauteng, and Lephalale, in Limpopo, allows for the provision of maintenance services in the gold, copper, platinum and coal mining sectors.

The centres optimise repair schedules, subsequently allowing for reduced travel times and making expert pump knowledge available. Local engineers at all service centres can also access Sulzer’s global organisation, which can deliver a full range of pumps-related services and electromechanical equipment repairs.

Sulzer supports the local and global mining industry, with pumping solutions for water supply, dewatering, leaching and process water, as well as cooling systems.

The company provides complete services for pumps, ranging from product specification, installation, commissioning, condition monitoring, trouble shooting and root cause analysis to general maintenance. It also provides services for rotating equipment such as motors and generators.

Blignaut highlights that efficient pump operations rely on several factors and, over time, parts can become worn and pumping applications can change.

Further, the fluid nature of mining operations means that Sulzer’s dedicated design and manufacturing facilities, which create new parts for obsolete equipment that is no longer supported by an original-equipment manufacturer (OEM), can offer cost savings to operations with tight margins.

“The greatest opportunities lie with existing assets in operation in the mining industry throughout South Africa and Africa. Sulzer applies its expertise in pump design and manufacturing to the equipment produced by other OEMs. There are many pumps that would benefit from retrofit projects or overhauls to ensure continued reliability,” he points out.

This can result in either direct replacements or the pumps can be designed to improve performance and efficiency for a current application.

“We address the challenges that can affect pump performance and deliver a solution that can improve efficiency, reduce operating costs and extend the service life. As markets and industrial sectors change, Sulzer identifies new challenges and addresses them through additional investment, where it is required to improve customer experience.”

Training Initiative

Sulzer also offers specialised training courses. Companies send operators and maintenance engineers for training.

“Training is often delivered at any of Sulzer’s manufacturing or servicing facilities globally, offering trainees the opportunity to get a hands-on experience and see a variety of pumps in various stages of manufacturing and/or overhaul. When trainees cannot be mobilised to a Sulzer facility, training may also be offered at a customer’s site,” says Sulzer Academy for pumps and systems head Christine Doerffel.

In this scenario, training would be accompanied by a walk around the site to observe the pump and its associated equipment in an operational environment.

The courses also provide attendees with opportunities to gather information from industry experts and focus on prominent concerns in different industrial sectors, thereby assisting companies in meeting the demands for increased efficiency and availability while addressing safety matters.

If training sessions are offered as an open seminar conducted at a Sulzer site, they can typically take up to four days and can include up to 12 attendees from different employers. Trainees can discuss concerns and participate in practical sessions that comprise inspections and strip-downs of pumps, as well as taking measurements of important components.

“The Sulzer Academy training courses are organised according to demand and businesses in South Africa and Africa can contact local service centres and arrange training sessions,” she adds.

The expertise sourced for these training initiatives extends to all major industrial sectors, using products designed for each application, particularly in the high-energy pump applications.

“The most common applications are in mining, oil and gas, power generation and water, but more specialised courses can be presented when necessary.

“Training courses can help customers identify best practice, ensure operating conditions are optimised, carry out maintenance activities effectively, and identify challenges that may require external assistance,” Doerffel notes.

Blignaut adds that the company has further diversified its offering to the mining market, developing a wheel motor exchange programme. This enables the company to minimise downtime for the customer, as it can use its large inventory of support parts at specialist centres and offer the in-house manufacturing of components that are difficult to find or have long lead times.

Customers have full visibility of the in-house testing data before shipment and are encouraged to be involved in the repair decision-making process to ensure the service suits their needs.

Article Enquiry

Email Article

Save Article

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation