Grindex submersible dewatering pumps prove their mettle in the Copperbelt

Grindex submersible dewatering pumps are seeing growing demand across Zambia and the DRC, where mining operations face tough underground water challenges

Integrated Pump Technology reports strong uptake of the Grindex N series pumps which deliver high flow rates of up to 100 litres per second for efficient mine dewatering

The Grindex H series is designed for applications requiring high heads, capable of pumping water to impressive heights of up to 180 metres in deep level mines

Grindex pumps are known for their rugged build and efficiency, helping mining customers maintain production and safety even in waterlogged underground conditions

Grindex submersible dewatering pumps are engineered for tough mining conditions, combining reliability, performance and low maintenance requirements

Built to handle abrasive and waterlogged environments, Grindex submersible pumps offer dependable dewatering solutions for both surface and underground mines

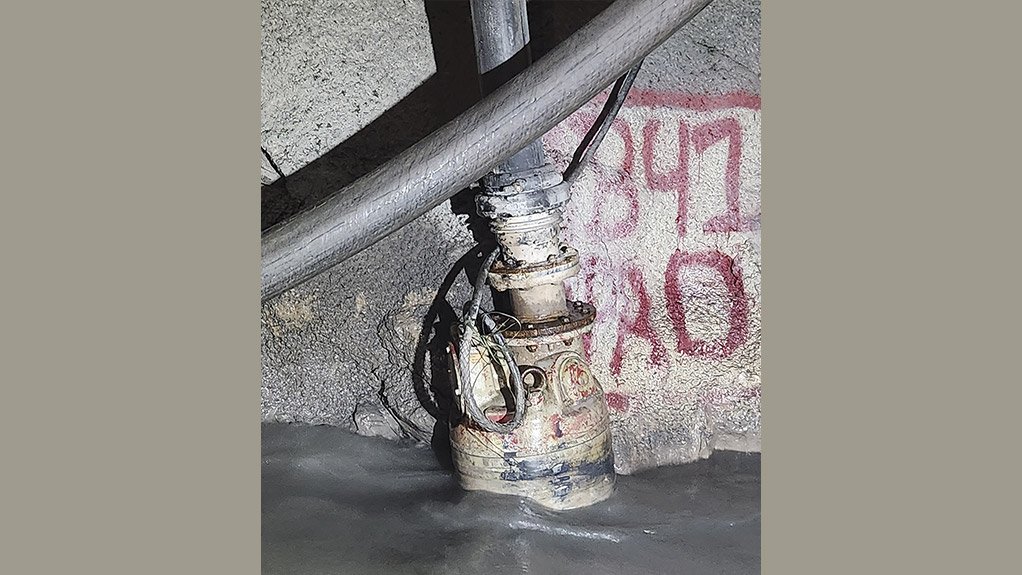

Grindex submersible dewatering pumps continue to gain significant traction among mining operations in Zambia and the Democratic Republic of Congo (DRC), where the demand for reliable and efficient dewatering solutions is on the rise. These pumps, renowned for their durability and high performance, have become a preferred choice for mines facing challenging underground water ingress conditions.

Jordan Marsh, Managing Director of Integrated Pump Technology, the official distributor of Grindex pumps in Southern Africa, confirms that the brand has built a solid reputation over the past decade in the most demanding dewatering applications. He anticipates a continued surge in demand as underground mining operations extend deeper, requiring even more robust pumping solutions.

“Dewatering in deep underground mines demands pumps that can handle high flow rates and high heads, while maintaining absolute reliability in extreme conditions,” says Marsh. “Grindex pumps have proven their ability to perform consistently in these environments, making them a trusted choice for copper mines in the region.”

Recent orders, received through Integrated Pump Technology’s distributor partner in the DRC were from a major copper mine and included a range of Grindex submersible pumps, spanning from 5.5 kW to 90 kW. Among these are the Grindex N series, capable of handling high flow rates from 20 litres per second up to 100 litres per second, and the Grindex H series, which can pump to impressive heads of up to 180 metres.

This particular mining operation has relied on Grindex submersible pumps for its dewatering needs since 2022, with consistently outstanding performance. Marsh attributes the ongoing preference for Grindex to the pumps’ rugged construction and high efficiency, both critical factors in maintaining optimum production levels and ensuring the safety of underground personnel in waterlogged areas.

To further support its growing base of Grindex users in the region, Integrated Pump Technology deploys teams regularly to assess dewatering applications and ensure that the correct pump solutions are in place. Additionally, through its local distributors the company provides technical support and spare parts availability, ensuring that downtime is minimised and operations remain uninterrupted.

“As mines go deeper, dewatering becomes an increasingly complex challenge. With Grindex submersible pumps, our customers have a reliable and cost effective solution that is built to withstand the harshest mining conditions,” Marsh concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation