Gugulethu project continues to meet expected timeline

JARMI STEYN The Gugulethu mine will reach commercial production by the end of November

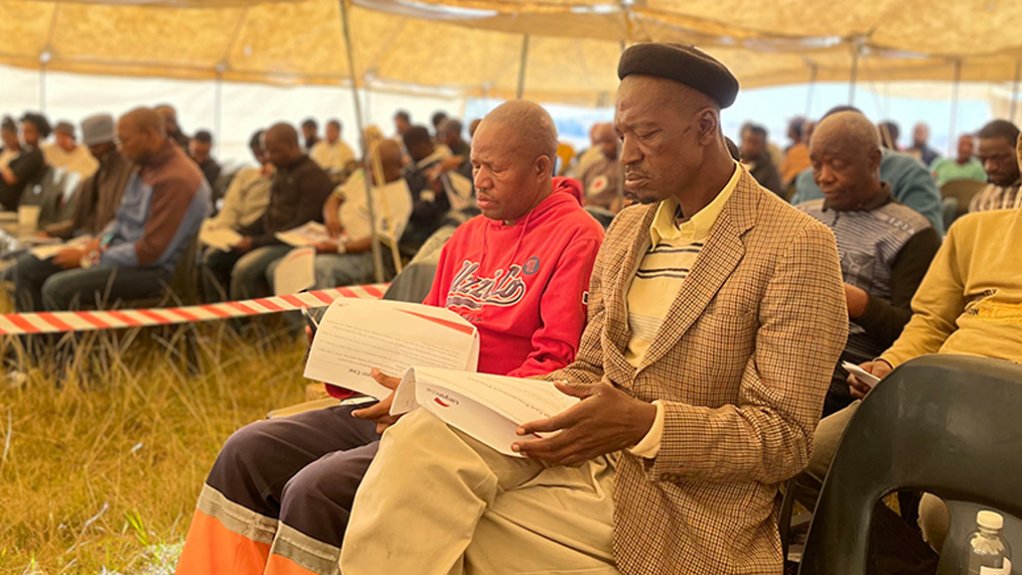

GUGULETHU PROCUREMENT DAY Canyon Coal's focus is to ensure upliftment and development within its hosting community

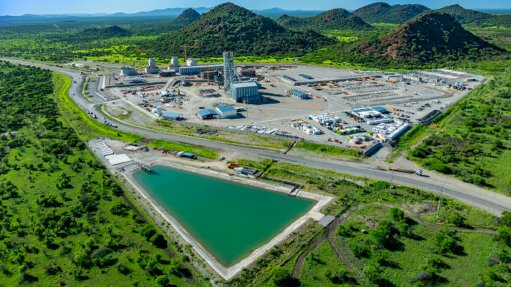

Coal exploration and mining company Canyon Coal, subsidiary of private investment firm Menar, has made “good progress” on the developmental phase of its Gugulethu project and expects to begin with the installation of the processing plant before the end of 2023, says Gugulethu GM Jarmi Steyn.

The 400 t/h coal processing plant will produce one product, but will also have the flexibility to produce sized products, such as large and small nuts, peas and duff, as well as spiral coal products.

The plant will also have a 28 t/h filter press system, which will reduce the Gugulethu Colliery’s water consumption by recycling mine water for use in processing.

The plant is expected to be operational by the end of October this year. The mine will reach commercial production by the end of November.

Steyn explains that the current focus is to complete the road construction to allow for easy access to Portion 5, which is the area where the infrastructure for the processing plant will be re-assembled.

Infrastructure for the plant is from the Hakhano Colliery. The infrastructure is being refurbished before it can be transferred to Gugulethu for re-assembly.

The bulk of the refurbishments, such as painting and the installation of new screens and conveyors, have been completed. Once the road is complete the plant will be delivered to the Gugulethu site.

Steyn explains that the installation at Portion 5 is scheduled to begin next week.

“We are confident that the plant will meet our deadlines,” she says.

The first phase of the Gugulethu project will comprise three pits and will allow for the extraction of 14.3-million tons run-of-mine coal, Steyn says.

While the heavy rains earlier this year impacted on project development, work was able to continue once the rains receded, with the company working towards meeting the project’s timeline.

“When the heavy rains subsided, we were able to pump the water out, do surface excavations and continue with operations as planned,” she adds.

Canyon Coal also expects to start and complete the mine’s box-cut in the first half of this year, once the topsoil is stripped at the plant area.

The company has secured contractors and received yellow equipment on the project’s site. The first consignment of mining machinery includes excavators, articulated dump trucks (ADTs), dozers and graders, along with other implements. It has also continued with an ongoing recruitment drive.

Further, Canyon Coal is committed to developing its pipeline of mining projects in South Africa.

This is evidenced by the total investment earmarked to develop the Gugulethu mine, which exceeds R1.4-billion.

Phase 1 of the project will require an investment of R600-million, while the development of the underground mining section will require a further R890-million.

Community Considerations

One of the first priorities of the project was to connect with the immediate community in Davel (Ward 10) in the Msukaligwa local municipality. This was achieved through the creation of a community stakeholder forum.

Steyn explains that the forum has been instrumental in assisting with the dissemination of information such as job advertisements and procurement opportunities.

Stakeholder engagement meetings provided a platform for the company to share crucial information about social and labour plan (SLP) procedures, procurement and employment opportunities.

In February, the Gugulethu project welcomed the first group of ADT, excavator, grader and dozer operators from the local community, who were trained and completed induction.

“Through the ongoing recruitment process, we have noted the different skills levels available in the community and hope to address some of the gaps through training opportunities that we expect to open up in future,” explains Steyn.

She adds that the World Economic Forum has emphasised the urgent need for skills development, stating a need to upskill about one-billion people by the year 2030 to support economic growth.

Steyn notes that this figure reflects how important it is for governments and companies to contribute towards the provision of skills opportunities.

The Gugulethu project has initiated its SLP, which aims to provide learnership and internship opportunities for local youth. This could assist in alleviating poverty, unemployment and inequality within the community.

“Upskilling employees also adds value to an individual’s personal career growth, while ensuring that the company has a strong team of competent professionals to handle operations,” Steyn explains.

Further, the company held a procurement day event for prospective suppliers of goods and services on April 13, 2023. The roadshow was aimed at assisting local suppliers with registration as vendors, explaining company procedures and upcoming opportunities as well as future enterprise and supplier development.

“We are very excited about the opportunities provided to our local suppliers for business as well as development. Our focus is to ensure upliftment and development within our hosting community,” Steyn concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation