Hydraulic solutions provider launches new sectional mobile valve

CLS SECTIONAL MOBILE VALVE Eaton's new valve was designed prioritise work functions, improving machine efficiency and safety

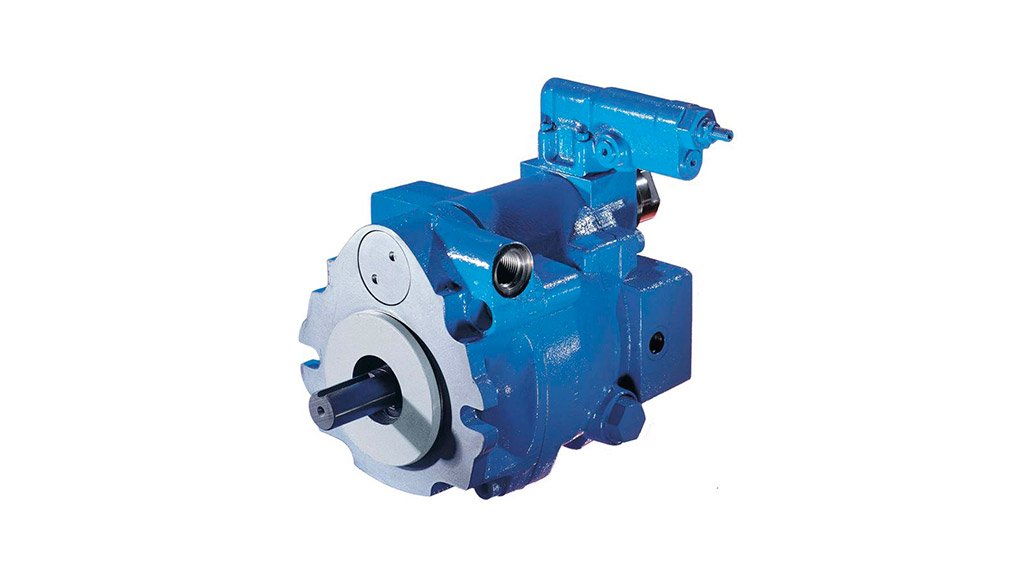

PVM VARIABLE PISTON PUMP Eaton's new variable speed drive solution reduces operational costs by eliminating cooling needs and allowing for downsizing

Power management company Eaton last month announced the launch of its CLS sectional mobile valve.

The CLS provides patented load sense bleed off, pre- and post-compensated load sense relief on each section, and a highly modular design with one of the smallest envelopes in the industry.

Built for mobile, off-highway equipment, including excavators, refuse trucks, forestry and agricultural machinery, the CLS sectional mobile valves enable end-users to prioritise work functions to improve productivity, machine efficiency and safety.

“The . . . CLS sectional mobile valve was designed to streamline features – adding value without increasing size or sacrificing flexibility,” says Eaton global strategy and planning manager Nadine Powell.

She adds that, “with a number of available features unique to many load-sensing valves, such as priority flow sharing and local load sense relief on each section, customers can design the valve to meet the distinctive needs of their machine”.

The pre- and post-compensated mobile valve offers up to ten working sections and available mid- inlet or customer manifolds.

The valve is available in models CLS100, CLS180, CLS250 or CLS350 to accommodate different flow requirements – 150 ℓ/min, 220 ℓ/min, 300 ℓ/min and 450 ℓ/min respectively.

Each valve can accommodate a working pressure inlet port of 350 bar and a maximum pressure outlet port of 25 bar.

New VSD

In June, Eaton announced a new variable speed drive (VSD) pump solution, which can provide up to 70% energy savings for equipment in the machine building, manufacturing, oil and gas and marine industries – depending on the machine duty cycle.

The industrial pump solution, available in open- or closed-loop motion control configurations, reduces operational costs by allowing quieter machine operation, reducing or eliminating cooling needs and allowing for pump downsizing.

The complete VSD solution can include one or more pumps, selected from Eaton’s offering of PVM variable piston pumps, Hydrokraft variable piston pumps or VMQ fixed vane pumps.

Together with the smart control of Eaton VSDs, such as the PowerXL DG1 general purpose drive or SPX 9000 high performance drive, the system can be controlled to match the precise load requirements of the current duty cycle.

“Energy consumption plays a significant role in overall machine operating costs, and, as energy costs increase, Eaton has worked to provide more efficient solutions without sacrificing safety or power,” says Eaton Hydraulics Group product strategy and planning manager Wayne Wang.

“By combining the proven reliability and availability of Eaton’s hydraulic and electrical solutions, we are enabling more sustainable, cost-effective indus-trial operations,” he explains

.Running pumps at a variable speed also reduces noise pollution, protecting operators’ hearing, while meeting noise regulations.

As equipment efficiency increases, oil coolers can be downsized, limiting the amount of oil used and extending the life of seals and oil.

Eaton Hydraulics notes that, with the costs of energy steadily rising, energy consumption is playing a more significant role than ever in the total cost of machine operation as the hydraulics industry is demanding energy efficient solutions, which also meet stringent govern- ment regulations for environ- mental protection, as a result.

As a power management com- pany, Eaton provides energy efficient solutions that help its customers effectively manage electrical, hydraulic and mechani-cal power more efficiently, safely and sustainably. Its 2014 sales were in excess of $22.6-billion, and its products are sold in more than 175 countries.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation