Trafo Power Solutions delivers mobile substation solution to Australian mine

The high-voltage side of the dry-type transformer, configured with secure cable terminations suitable for demanding mining applications

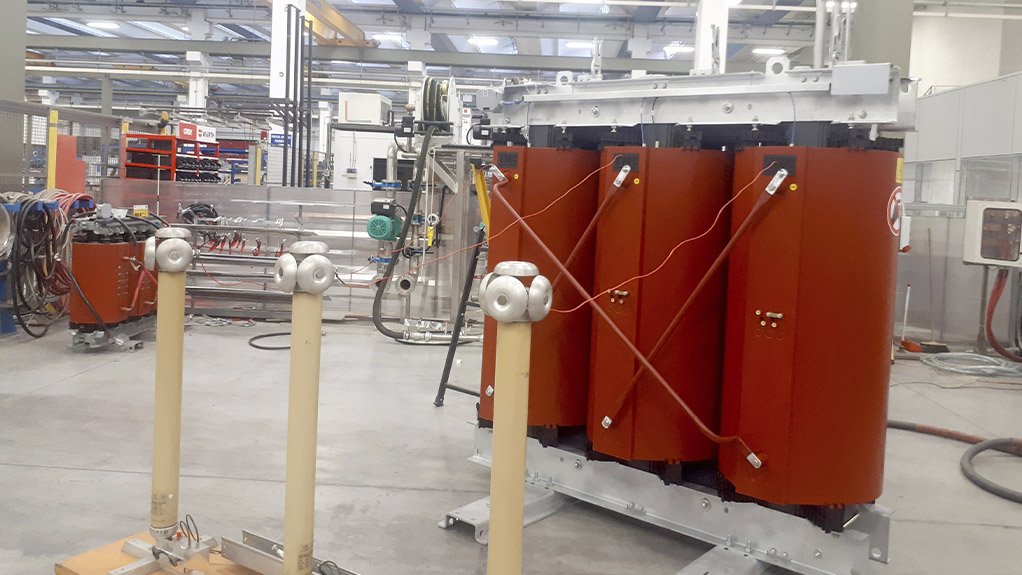

Partial discharge testing being conducted to verify the integrity of the insulation system and confirm the dry-type transformer’s compliance with performance and safety standards

A close-up view of the high-voltage connection on the dry-type transformer, highlighting the secure cable terminations and insulation system used to ensure operational safety

This article has been supplied.

A depth of experience across industries – combined with in-house design expertise and a responsive approach to business – has underpinned Trafo Power Solutions’ recent success for an Australian mining customer.

According to Trafo Power Solutions Managing Director, David Claassen, the company designed and supplied a robust skid-mounted transformer solution for an opencast mine in Queensland. The turnkey substation project allows the customer to step up their generated power supply from 400 V to 6,6 kV, with the mobile substation able to accompany the customer’s generator set around the mine site.

“Our 2,000 kVA substation includes the necessary low voltage and medium voltage switchgear, and gives the customer quick and easy plug-and-play functionality when moving locations,” says Claassen. “This means there is no need for time consuming termination of cables when the unit is moved and reconnected to the generator. To facilitate mobility, the skid is equipped with hooks for dragging as well as push bars for moving it into position.”

He notes that it was important to take into account the high vibration levels when specifying the components to be included in the design, with rigid mounting for strength and the use of anti-vibration equipment. Meeting the region’s specific standards was also an important aspect of the contract.

“The design needed to be conducted within the requirements of Australia’s national standards and specifications, with which we have extensive experience from our work there with other customers,” he explains. “Further, the customer also wanted certain equipment specified that was common in the Australian market as this was an important consideration to ensure adequate technical aftersales support.”

This demonstrates the flexibility in Trafo Power Solutions’ design process, Claassen points out, which can accommodate and meet any national standards – as well as to incorporate customer preferences for certain locally sourced equipment. This was especially relevant in the low voltage aspects of the design, such as protection relays and monitoring systems.

“We are not rigid in the options that we consider, and can easily adapt to customers’ choices that best suit their preferences and local market availability,” he says.

Claassen highlights that inspections and witness testing remain a core priority in fulfilling export orders, in spite of the customer’s physical distance from the country of design and manufacture. The Covid pandemic had encouraged the development of various communication technologies which the company now harnesses to ensure the customer’s involvement in the technical aspects of the contract.

“We put this technology to good use, allowing the customer on this project to carry out all necessary inspections and factory acceptance testing remotely and to their full satisfaction,” he says. “At Trafo Power Solutions, we take pride in being easy to work with and finding creative solutions - even across long distances and under tight deadlines.”

The contract has been an indicator of the company’s growing success not only in the international market, he says, but also in its journey from being a transformer supplier to becoming a turnkey electrical power solutions provider. Having initially carved a niche for itself in dry-type transformer applications in Africa, Trafo Power Solutions is now evolving rapidly on the strength of its design and engineering capability – as well as its in-depth technical understanding of various aspects of electrical projects.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation