Improved Local Design Of Enduron Vibrating Screens By Weir Minerals

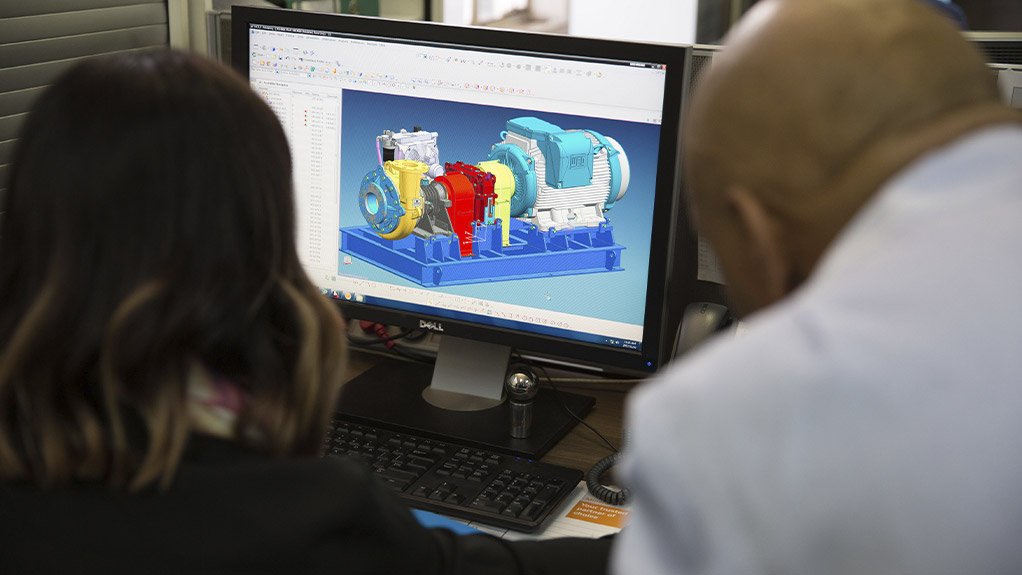

With its extensive range of Enduron® vibrating screens proven in the field, Weir Minerals Africa is now locally designing and manufacturing new-generation linear motion vibrating screens. South Africa also hosts Weir Minerals’ global screening and separation technology group.

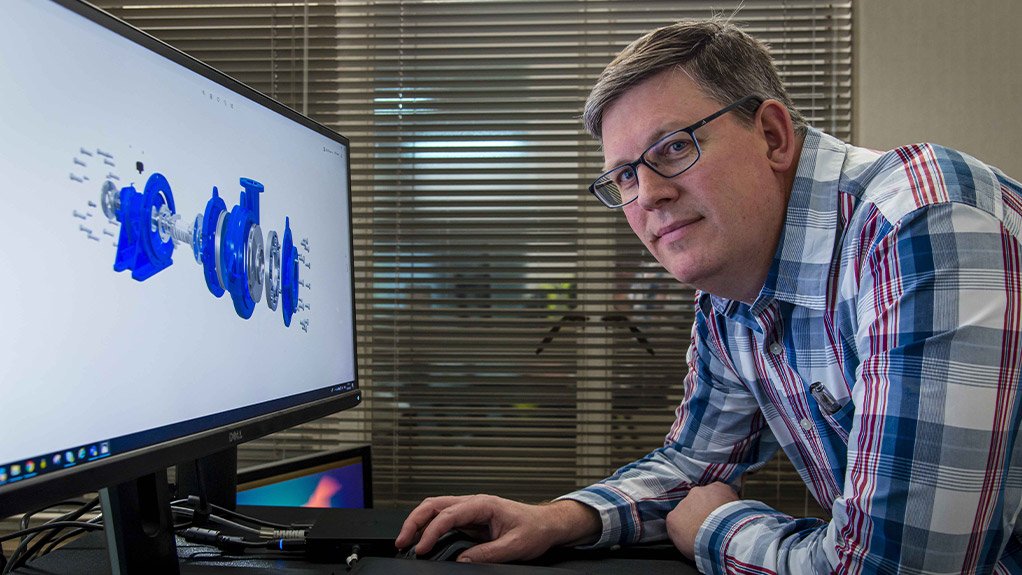

According to Christian Stehle, head of engineering at Weir Minerals Africa, this design capability provides the flexibility to produce vibrating screens to suit each customer’s plant layout. At the same time, the designs will optimise cost, efficiency and performance. South Africa also hosts Weir Minerals’ global screening and separation technology group.

“This expertise ensures that our robust Enduron vibrating screens provide exceptional classification and dewatering screening performance,” says Stehle. The screens are deployed in a wide range of minerals processing applications. He notes that vibrating equipment is generally more challenging to design than static equipment due to the high frequency cyclic loading to which the machines are subjected.

“The final design must address key criteria like screening efficiency, throughput and loading, while still operating within the acceptable fatigue life limits of the materials of construction,” he says.

Stehle highlights that the use of Finite Element Analysis (FEA) tools allow engineers to optimise screen life by obtaining the stress and deflection levels in the equipment and applying the appropriate structural design and utilisation of materials in the areas experiencing high stresses.

“Traditionally, screen designs used to be heavier in an effort to extend the life of the equipment,” he says. “Using FEA tools during the design stage allows us to retain structural integrity while actually reducing the overall weight of the machine.”

While there are areas of high stress on the equipment that need more strength, technology tools indicate where lower stresses occur. In these areas, less steel can be used to make the structure lighter. Leveraging this technology, the weight of some new-generation screens has been cut by up to 15%.

One of the new, modern screen designs is part of a recent Weir Minerals Africa complete comminution plant contract for a South African mining project. The scope includes two crushing stations, a screening station and all the related feed chutes, bins and conveyors.

Stehle notes that Weir’s Synertrex™ IoT platform can also be applied to monitor and improve the performance of its vibrating screens. Synertrex™ technology is an industrial internet of things (IIOT) system that allows operators to monitor every aspect of their equipment’s operation, to prevent problems and increase throughput.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation