In-house engineering expertise give mines valuable flexibility

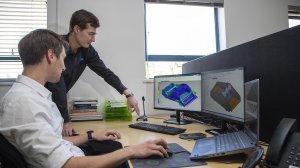

Sandvik Rock Processing’s design and engineering process involves close collaboration with customers to understand their specific needs

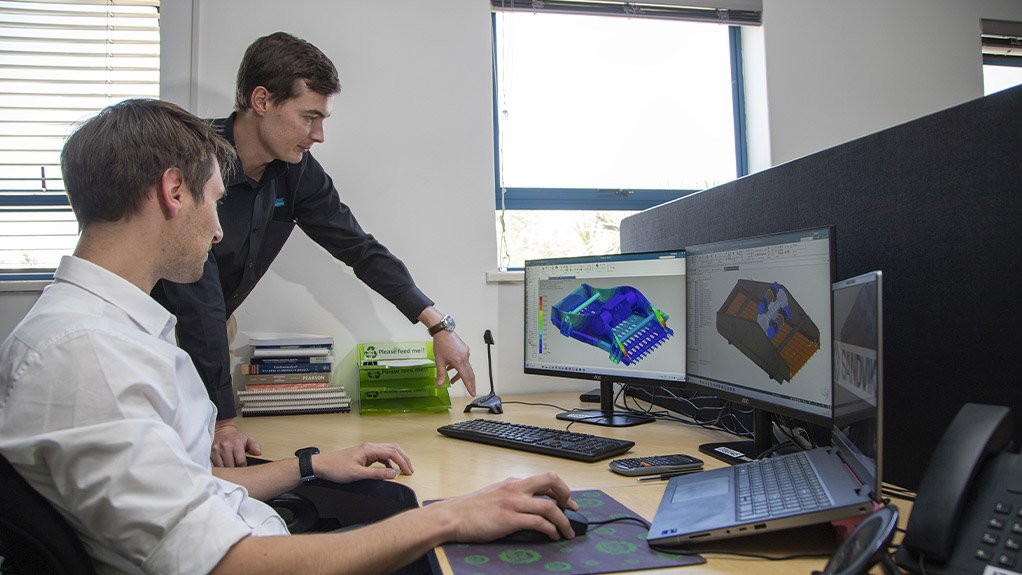

Sandvik Rock Processing’s design philosophy provides the mine with more agility in production

This article has been supplied.

With its well established design and manufacturing capabilities in South Africa, Sandvik Rock Processing delivers customised and standard vibrating equipment solutions, including screens and feeders, to customers that enhance future flexibility.

Gideon de Villiers, Engineering Manager at Sandvik Rock Processing, says the company has built its success on decades of field experience – and the nurturing of its mechanical and metallurgical engineering skills base. Its 21,000 m2 facilities, in Johannesburg South Africa, house modern workshop and testing facilities that are ISO 9001:2015 accredited and produce world class solutions for global markets.

“A key aspect of our design philosophy is to ensure that our customers can be more agile when their operational demands change,” says De Villiers. “This allows cost effective modifications to be made relatively quickly, without unduly disrupting production.”

He emphasises that this is possible due to the depth of vibrating equipment related expertise that the company has developed, where in-house mechanical and metallurgical experts can come together to find screening and feeding solutions. It is also thanks to the far-sighted initial design of Sandvik Rock Processing’s screens, which carefully take into account the opportunities for future modification.

“There are various technical complexities to consider when creating a design that allows future flexibility,” he explains. “Achieving modified results with an existing machine – rather than replacing it – means a more sustainable solution with less waste. At the same time, the new design must accurately match the new requirements, which we can test and validate using technology like Finite Element Analysis (FEA).”

He notes that efficient design and engineering also make use of cutting edge software and tools such as advanced CAD and CAE solutions allows for sophisticated modelling, analysis and prototyping.

“We attract, retain and nurture some of the best skills in the sector, and encourage continuous improvement through training, academic programmes and specialised professional conferences,” says De Villiers. “We also collaborate with universities, research institutions and laboratories to promote cutting edge research and innovation projects.”

A recent success for an iron ore mining customer in the Northern Cape saw Sandvik Rock Processing extend the life of the mine’s scalping screen deck from six weeks to six months – by stiffening the frame and improving the panels’ rubber compound.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation