Innovation driving the future of green hydrogen

ENPROTEC’s green hydrogen production plants are built around decarbonising sectors and applications, such as heavy-duty mobility, which is central to mining and other industrial operations.

At ENPROTEC, green hydrogen is increasingly recognised as a future cornerstone of industrial decarbonisation, with its potential to decarbonise sectors and applications, such as heavy-duty mobility, which is central to mining and other industrial operations. However, producing green hydrogen reliably, safely, cost-effectively, and at scale requires advanced and innovative engineering solutions.

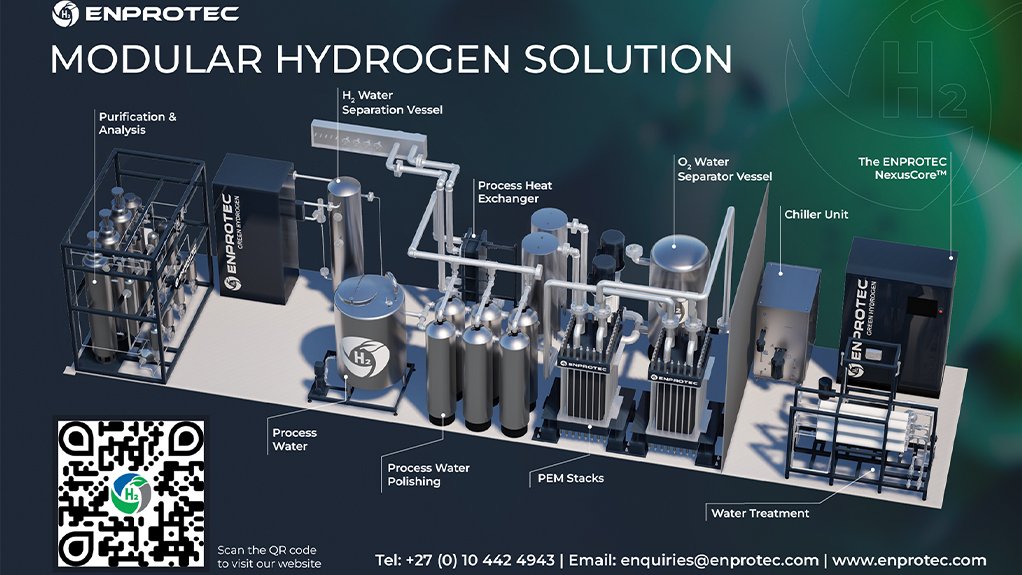

Green hydrogen plants must operate as intelligent, adaptive energy systems, by integrating various processing steps, while considering often fluctuating inputs and stringent safety requirements. Multi-disciplinary engineering applications group ENPROTEC’s green hydrogen production plants are built around this reality – combining rigorous thermodynamic modelling and dynamic simulations, into a modular, containerised design to enable hydrogen facilities that are predictable, scalable and able to overcome the sector’s principal barriers.

Electrolysers, purification units, storage modules, water treatment systems and advanced power conditioning systems are packaged into compact pre‑integrated containerised units. This significantly reduces civil work requirements, limits site integration complexity and shortens project deployment schedules. This approach further enables easy scale-up, with the addition of supplementary modular units, without the need for major facility redesigns or modifications.

Further, the plant architecture has been intentionally developed to manage renewable intermittency. The system interfaces directly with solar PV, wind or hybrid power-supply approaches, adjusting production through real‑time load tracking and synchronised control. Electrolysers operate at broad turndown ratios, enabling efficient operation even at low renewable availability, while power electronics and high-

speed instrumentation allow rapid response to sudden changes in supply. The advanced NexusCoreTM control systems coordinates pressures, temperatures and general stability across process units, such that the produced hydrogen purity remains within specification during ramp-up and turn-down scenarios. This further allows these units to operate reliably at sites with power

supply stability constraints.

Within the green hydrogen industry, infrastructure availability – particularly with regard to storage, transportation and distribution – remains a global challenge. The deployment of containerised production units aims to address this challenge by enabling on‑site production and modular point‑of‑use implementation.

This approach eliminates the need for extensive supporting infrastructure typically required for larger centralised plants and has the potential to enable and fast-track green hydrogen uptake, providing direct access to hydrogen as an energy carrier.

Another challenge facing the industry, is the safe and reliable operation of these production facilities. Within the ENPROTEC design philosophy, safety and optimisation are treated as a unified control problem. The system’s NexusCoreTM driven automation framework provides real-time data integration, with AI‑assisted monitoring for anomaly detection – identifying early signs of equipment degradation, sensor drift and other relevant safety risks. With the implementation of dynamic power regulation, automated fault responses and embedded shutdown sequences, operation risk mitigation is enabled with minimal operator intervention. In the event of credible incidents, the system executes controlled depressurisation, isolation and inerting procedures, ensuring compliance with best‑practice safety engineering.

The system is designed to address some of the key barriers to green hydrogen adoption. The result is a modular plant that adapts to real‑world variability while consistently producing high grade hydrogen at a competitive cost – a practical and scalable foundation for the sector’s next phase of growth.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation