Kal Tire driving mining sustainability in South Africa through innovation

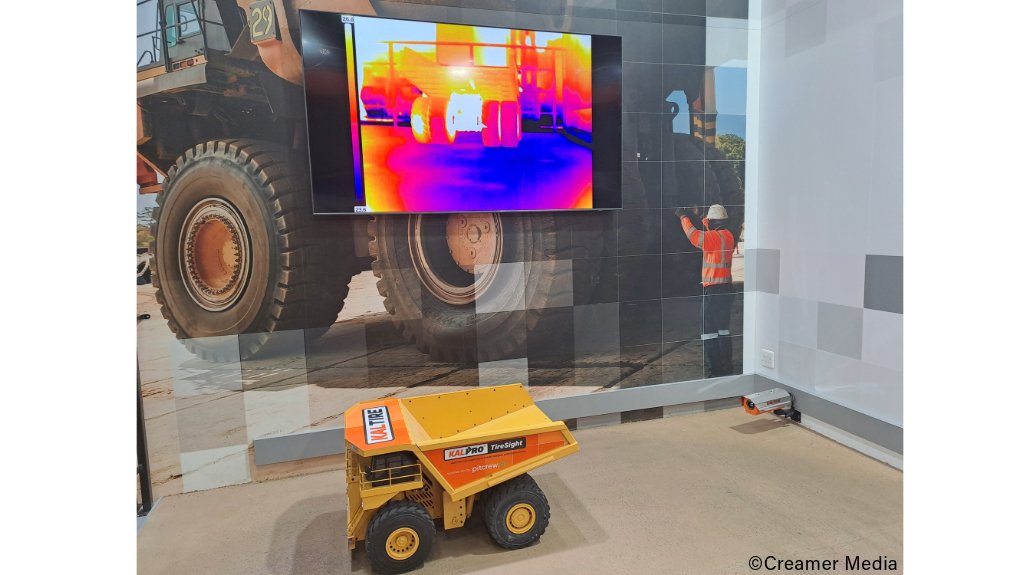

TireSight display at Electra Mining Africa

Photo by Creamer Media's Tasneem Bulbulia

WheelJaws display at Electra Mining Africa

Photo by Creamer Media's Tasneem Bulbulia

Maple Program and Ultra Repair display at Electra Mining Africa

Photo by Creamer Media's Tasneem Bulbulia

Thermal conversion

TireSight on site

Ultra Repair on site

Canada-headquartered independent tyre dealer Kal Tire, through its Mining Tire Group, has invested considerably in innovation to provide mining customers with tools and offerings that can help them reach their environmental, social and governance (ESG) goals.

In this vein, the company this year launched its sub-brand, KalPRO, which houses all of its proprietary tools and offerings that are aimed at bolstering sustainability, safety and productivity at mine sites.

Kal Tire’s Mining Tire Group provides international mining tyre service and supply, operating on over 150 mining sites across five continents.

The company showcased some of its KalPRO innovations at its stand at the Electra Mining Africa exhibition, held last week in Johannesburg, South Africa.

While the company already has an established presence in Africa, it is aiming to grow this further, as well as enhance sustainability at mine sites in the region through increased uptake of its innovations.

In South Africa, where the company’s business was currently predominantly in underground mining, it was looking to “aggressively” expand its footprint in surface mining over the next few years, leveraging on its global expertise in this arena and also expanding the reach for its innovations, Kal Tire Mining Tire Group Southern Africa VP John Martin told Engineering News and Mining Weekly in an interview at Electra Mining.

He highlighted that Africa held considerable promise, as it was host to some of the largest untapped resources in the world, while mining activities were set to increase as governments matured. “We are seeing lots of interest and investment in Africa. There is definitely an upbeat atmosphere about what the continent can deliver.”

Martin pointed out that the mining industry was significantly committed to meeting ESG requirements and targets and said the company was ideally positioned to assist with reaching these, with its innovations geared towards the circular economy.

Services and offerings encompass extending the life of tyres as long as possible in mining conditions and then providing recycling options at the tyres’ end-of-life.

KalPRO

“Our message at Electra Mining this year is to consider KalPRO. If you engage with Kal Tire, you are not just engaging with a tyre supplier or service provider. We offer much more – in-depth value in sustainability, productivity and ESG,” Martin averred.

As alluded to, KalPRO encompasses the six propriety tools and six propriety offerings that the company is actively marketing to customers. These have been developed at the company’s Innovation Centre in Canada, to address challenges that tyre technicians in the field have identified with tools and processes.

“We invested considerably in innovation and doing things differently for customers. We wanted to capture that under a sub-brand that they can then recognise. KalPRO thus elevates the prominence of the innovations that are delivered to customers,” Kal Tire Mining Tire Group communications and marketing director Tracy Cobb-Reeves explained.

KalPRO’s tools are the WheelJaws, Gravity Assist Tooling Rig (GATR), RamDrive, ValveShield, SpringLock and PowerFlow.

The company showcased its WheelJaws product, which helps to improve safety for tyre technicians during tyre installation and removal, at the Electra Mining event.

It was developed over about two-and-a-half years through internal innovation, with the company aiming to address what it considers a currently unsafe operating process in the industry, whereby the technician is in a potentially hazardous area when removing lug nuts.

WheelJaws are secure, remote-controlled clamps that enable safe tyre removal, removing the technician from the risk area. It is designed for wheels and rims from 51 to 63 inches.

Meanwhile, KalPRO’s offerings are TireSight, Thermal Conversion, Maple Program, Ultra Repair, Ultra Tread and Tire & Operations Management System (TOMS).

TireSight enables autonomous tyre inspections to allow mines to keep trucks running safely and more efficiently. Thermal imaging cameras capture images of the truck as it passes the autonomous inspection station.

Australia-headquartered company Pitcrew AI’s technology is used to scan for issues on the tyres and this data, along with data from other sources such as tyre pressure monitoring systems, is fed into the TOMS. The 24/7 condition monitoring team reviews the information to ensure nothing is overlooked.

Once validated, TOMS automates work orders to ensure critical issues are addressed as required. Site service teams can then perform the necessary maintenance and repairs, and reliability analysts work with customers to determine goals for tyre performance and productivity for the long haul, using the data gleaned from this system.

The company stressed that TireSight would increase jobs and skillsets, as more labour and expertise would need to be onboarded for condition monitoring.

Moreover, it is looking to improve TireSight further to predict issues before they occur, so that these can be proactively managed, thereby reducing downtime and extending the life of tyres.

Also important is the company’s Thermal Conversion offering, which feeds into its off-the-road (OTR) tyre recycling facility in Antofagasta, Chile.

“Stockpiles of mining tyres are becoming a significant problem in the industry and are weighing heavily on mining operators and their ESG targets. Recycling of these is therefore becoming a significant priority,” Martin stressed.

Set up three years ago in response to end-of-life tyre legislation in Chile, the facility uses a thermal conversion process to convert OTR tyres to their base elements for repurposing.

Four products are realised from this process – synthetic gas, which is fed back into the process to help operate the plant, as well as steel, oil and carbon ash.

The oil could be cleaned slightly and repurposed for blending purposes or by mining companies to create certain explosives, Martin explained.

Further, the company is installing a purification system at the site, slated for completion at the end of the year, where carbon ash will be refined into carbon black so that it can be used to manufacture new tyres.

The facility was an exemplification of the company’s circular economy initiatives, Martin said, highlighting its relevance for the country and region.

He pointed out that the system was scalable and could be set up anywhere in Africa should a feedstock agreement be realised with a customer.

Also on show was the company’s Maple Program offering, launched in 2019 to give customers verified data to demonstrate how they are reducing Scope 3 emissions by making use of Kal Tire retreads or repairs of existing tyres.

The programme has been expanded to include a larger range of tyre sizes, as well as transportation modes, to enable enhanced carbon emissions savings for mines that repair or retread tyres locally, rather than buying new ones.

Therefore, customers can save on fuel and carbon in raw material and the production of new tyres, as well as emissions from transportation, as Kal Tire retread and repair facilities are usually on site or in the region compared with tyre manufacturers that are often far away.

With the programme, customers receive a yearly certificate with data from the company’s own-developed carbon calculator on the carbon emission and oils savings of extending tyre life.

The programme has garnered interest in some regions in Africa, including from gold mines in West Africa; however, South Africa has proved challenging as the harsher underground mining conditions are not conducive for repairing and retreading tyres.

Nevertheless, with the company’s drive to extend its surface mining footprint, it would also look to drive an uptake of the programme at these sites going forward.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation