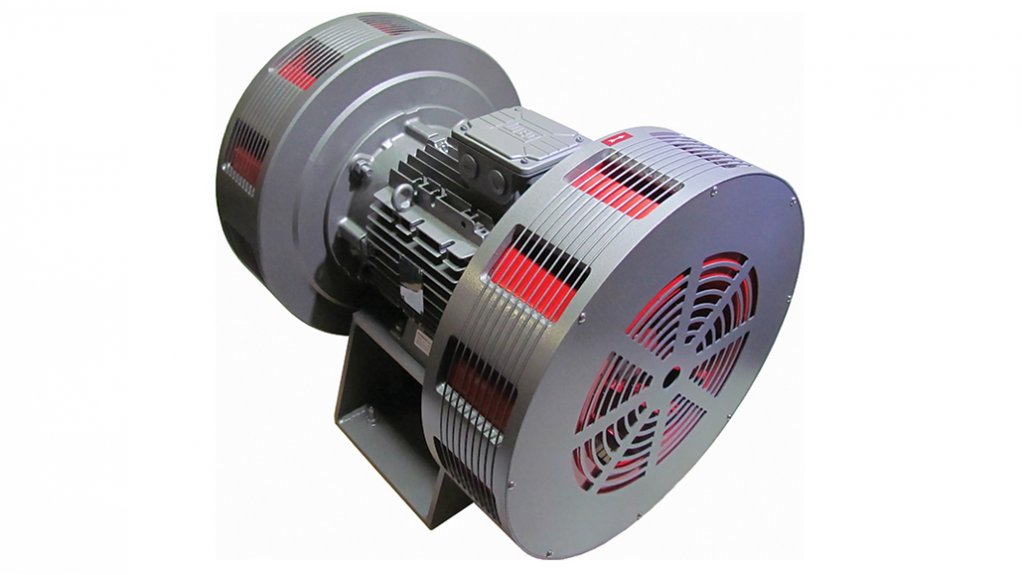

Kama’s Sirenco 15D the only locally made 15 km long-range siren

After being in production for more than 30 years, the 120 kg Sirenco 15D, an outdoor, weatherproof industrial siren, is currently the only locally produced siren with a range of up to 15 km.

These units are widely used in the mining sector locally and internationally, according to audible, visual, and flame-proof equipment manufacturer Kama Industries, located in Roodepoort, Gauteng.

Notably, Kama has experienced substantial growth in its international markets, which include other African countries, as well as the UK, Australia and Russia, owing to the quality and effectiveness of its products, says Kama marketing manager Istene Rousseau.

“In international markets, the Sirenco 15D exceeds competing motor-driven products in terms of manufacturing lead times and overall product quality.”

Comprising entirely of locally produced content, the Sirenco 15D includes a durable aluminium body and a 7.5 kW continuous rated electric motor, which is available in three-phase voltage. End-users also have the option of including a shutter valve and an anti-icing unit.

The product is suitable for all signalling or alarm applications where a heavy-duty motorised siren is required either indoors or outdoors as it offers a sound output of 145 dB at 1 m.

“The very powerful low frequency sound output ensures a sound distance of up to 15 km during favourable conditions. This is our largest siren in the Sirenco motorised siren range and comes with a reliable two-year guarantee,” explains Rousseau.

Introduced in 1989, early on in Kama’s product development stage, the Sirenco 15D was launched to satisfy demand for a long-range loud siren needed for warning and emergency alarms in the industrial and mining sectors. The product has also been used for lightning detection on golf courses and emergency and warning applications at airports, harbours and prisons.

“The development process was actually quite quick, as the design is a scaled-up version of smaller units available on the market. It took two to three months to develop the Sirenco 15D and six to eight months to introduce the product to the market,” explains Rousseau.

Over the years, the product has undergone continual development and advances, which include improving the materials used to manufacture the siren as well as its motor for longevity purposes.

Additionally, Kama has increased the stability and strength of the siren with the introduction of the Sirenco 15D Dragline, which can withstand the harsh operating conditions associated with dragline excavators employed at mines.

The Sirenco 15D is manufactured at the Kama factory in Robertville, where processes such as machining of parts, coating and spray-painting, assembly and quality testing are involved in the siren’s production.

The IP55-rated siren limits dust ingress and is protected from low-pressure water jets from any direction.

On average, eight units are produced a month; however, Kama has the capacity to make 50 to 100 units if it has access to the required raw materials.

To date, more than 500 units have been sold worldwide. The Sirenco 15D can be bought off the shelf through Kama’s distributor network. However, the company does try to keep some units in stock given that the average lead time to manufacture the Sirenco 15D is two weeks.

Kama complies with the International Electrotechnical Commission system for certification to standards relating to equipment used in explosive atmospheres. Additionally, the company adheres to ISO-9001:2015 quality management systems standards.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation