LHDA advances Phase 2

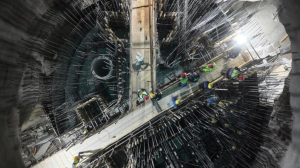

POLIHALI GATE SHAFT The LHDA is steadily progressing the construction of the Polihali dam and transfer tunnel under the Phase ll water transfer works

KATSE TBM ACCES ADIT The access TBM Access Adit was completed early in October and the TBM has since advanced 173 m at the main tunnel.

The professional body responsible for the Lesotho Highlands Water Project (LHWP) operations and maintenance, the Lesotho Highlands Development Authority (LHDA), is steadily progressing the construction of the Polihali dam and Polihali transfer tunnel as part of its Phase II water transfer works. The tunnel is set to be substantially completed in 2028 and the dam will achieve the same level of completion a year later in 2029.

By the end of September 2025, the dam was 37% complete and the tunnel was about 46% complete. The Phase II project will produce numerous benefits for Lesotho and South Africa, says LHDA public relations manager Mpho Brown.

He cites, for example, that water flow to South Africa will be increased, while Lesotho will increase its hydropower generation through additional flows through the existing Muela hydropower station and the construction of Oxbow hydropower scheme, which Brown says is at the detailed design and engineering stage.

Contracts have been awarded for engineering design, construction supervision and environmental- and social-impact assessments. The hydropower element will help to reduce Lesotho’s reliance on imported energy.

“Water stored in the 5 053-ha Polihali reservoir will be transferred through a 38-km gravity tunnel to the Katse reservoir. From there, the water flows through existing infrastructure, including tunnels and the Muela hydropower station, before reaching South Africa’s Gauteng region.”

He also notes that the current 780- million cubic metres of water a year will receive an incremental increase in water supply for domestic, agricultural and industrial use, up to a maximum of 1 270-million cubic metres a year.

Polihali Progress

Brown highlights that several milestones were achieved at the dam by the end of the third quarter of the 2025/26 financial year. These included the excavation of the main dam abutments, the saddle dam, intake tower and the plinth, all of which are complete. The spillway excavation is ongoing and there is also notable progress on the construction of the main dam plinth, foundation grouting works and rockfill placement processes.

“The main dam wall is achieving a rockfill placement of about 18 882 m2 every day – equivalent to 7.5 Olympic pools of material daily. To date . . . over 4.88-million cubic metres of rock have been placed in the main dam. The saddle dam is also progressing steadily, with over 100 710 m2 of rock placed.”

Additionally, the internal plinth consolidation grouting on the main and saddle dams have been completed, while the spillway excavation is nearing completion.

“The completion of the internal plinth consolidation grouting on the main and saddle dams enabled the start of the extrusion of the 500-mm-high curbs. “This was followed by rockfill placement on the upstream side, which necessitated the excavation of 2.5-million cubic metres of hard rock. When completed, 95 300 m3 of concrete will be poured for the spillway approach, chute tunnel and the permanent bridge for the roadway over the top of the dam.”

Brown adds that there has been a breakthrough of a bottom tunnel outlet at the dam, which is about 9.25 m high, 6 m wide and about 500 m long. The excavation of both the top and bottom headings, with the top heading being advanced by about 2.7 m every day using the drill-and-blast method, is nearing completion.

The construction of the 38-km transfer tunnel (between Katse and Polihali dams) is under way. Tunnel boring machines (TBMs) will be used to excavate the main tunnel while the drill-and-blast method is used to excavate the access adits and gate shafts.

At the Katse end, excavation of the TBM Access Adit was completed early in October and the TBM has since advanced 173 m at the main tunnel.

“At the Polihali end of the transfer tunnel, excavation is also progressing steadily . . . the assembly of the second TBM was recently completed at the portal, with the TBM entering the tunnel in early November ahead of its launch in early 2026. This launch will mark the start of TBM excavation from the Polihali end.”

Outlook

Brown says Phase II of the LHWP will allow for the deployment of modern construction technologies and will place significant focus on environmental considerations such as compliant wastewater and sewage treatment plants.

It will also contribute to the improvement of livelihoods for the Basotho people, as many jobs will be created for skilled and unskilled workers through the LHDA Livelihoods Restoration Master Plan. To date, Phase II has created employment opportunities for 3 791 unskilled and 12 226 skilled/semiskilled workers. It has also employed 68 young professionals.

“A key tenet of the ten-year strategy, and the first of the five strategic goals, is inclusive access to water and electricity. “The key word, ‘inclusive’, signifies a deliberate effort by the LHDA to ensure that, without any prejudice to the LHWP’s mandate to deliver water to South Africa, the project will deliver water within the borders of Lesotho as well, especially for communities directly affected by the project,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation