Lindi Jumbo graphite project, Tanzania – update

Photo by Walkabout Resources

Name of the Project

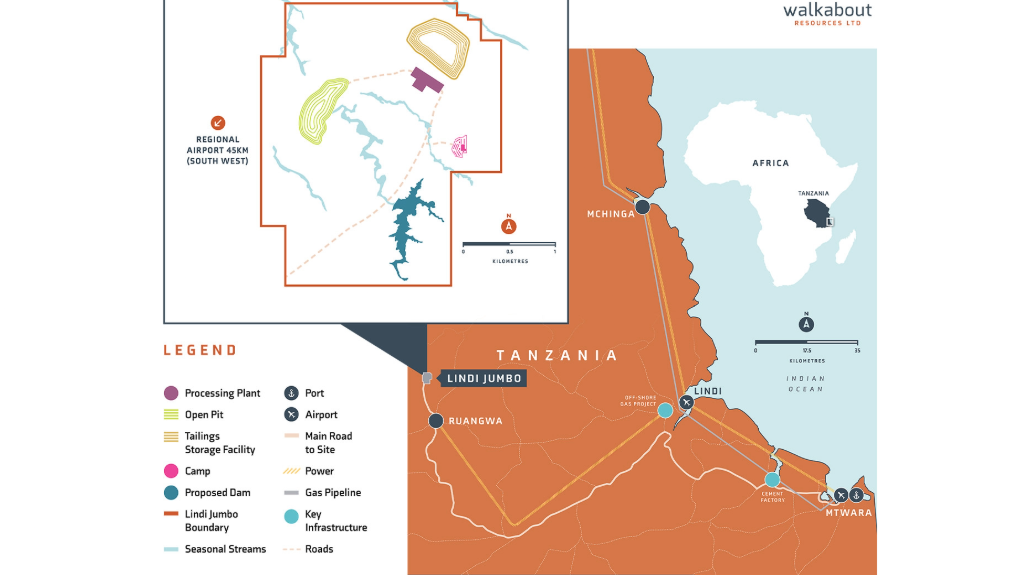

Lindi Jumbo graphite project.

Location

South-east Tanzania.

Project Owner/s

Walkabout Resources.

Project Description

The Lindi Jumbo project has mineral ore reserves of 5.15-million tonnes grading 17.9% total graphitic carbon for 987 000 t of contained graphite.

The mine life has increased from 20 years in the 2017 definitive feasibility study (DFS) to 24 years in the enhanced DFS to produce 40 000 t/y of graphite.

Once commissioned, Lindi Jumbo will officially be the first modern, large-scale graphite mine in Tanzania, as well as the first critical minerals asset in the country to go into full production.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The pretax net present value has increased from $302-million, at a 10% discount rate in the 2017 DFS, to $335-million in the enhanced DFS. The project’s pretax internal rate of return is estimated at 142% in the enhanced DFS, from 108% in the 2017 DFS. The payback period is less than two years.

Capital Expenditure

With the contracting of the power and camp scope changes, and the Lindi Jumbo plant construction nearing completion, the final estimated capital cost for the mine is $34.5-million, up from the $27.8-million estimated in the original DFS, Walkabout said on September 7, 2023.

The bulk of this cost was incurred in 2021.

Planned Start/End Date

The Lindi Jumbo project is preparing for operational readiness in early 2024.

Latest Developments

Walkabout Resources has confirmed that ore has successfully advanced through the concentrating circuit to produce an unscreened wet concentrate, with commissioning activities continuing to ramp up.

Problems with the consistency of fuel supply to the burner that will generate heat for the rotary dryer have, however, slowed commissioning progress of the back-end plant.

Walkabout has said that a representative of the company that manufactured the burner and carried out its factory-acceptable testing is on site and will oversee the commissioning of the burner and necessary training of the responsible operations team.

The successful commissioning of the back-end plant will allow for the wet commissioning of the screening and bagging units.

Once the dryer is brought up to expected performance levels and the circuit runs in its entirety, plant throughput can increase significantly and consistently.

Owing to unforeseen delays in approvals from the Tanzanian Mining Commission, Lindi Jumbo is yet to award a fuel supply contract and currently depends on temporary fuel supply arrangements, which have a higher risk of disruption from poor weather or unreliable supply.

Without the requested permanent fuel infrastructure established on site, the mine has had to deal with some fuel shortages over the past month and is actively engaged with the Mining Commission to expedite the approval process for an acceptable long-term arrangement.

From a funding perspective, Walkabout says until sufficient cash flow from product sales is available, the operating costs of Lindi Jumbo are being funded from a senior debt facility, with a final drawdown of $20-million having been made in March.

Another standby facility of $5-million remains available if required and can be drawn before the end of September.

Walkabout ultimately aims to ramp up production rates to the 40 000 t/y design capacity within four months. Once throughput levels are sustained, the company will focus on grade and flake size distribution optimisation to ensure the plant performs according to its design parameters.

Thereafter, Walkabout’s metallurgical team at the mine will aim to improve the processes pertaining to recoveries.

Meanwhile, the high-grade run-of-mine stockpiles of material have increased by about 15 000 t of free-dig graphite ore, bringing the total ore stockpile as of May 2 to 34 000 t, which is more than a month’s supply for the plant at nameplate capacity.

With Lindi Jumbo’s production being unpriced, it will capture full value from the current market shortage.

Key Contracts, Suppliers and Consultants

TNR (bulk earthworks civil engineering works contract); Yantai Jinpeng Mining Machinery (EPC); and Axis Group International (EPC oversight).

Contact Details for Project Information

Walkabout Resources, tel +61 8 6298 7500 or email admin@wkt.com.au.

Article Enquiry

Email Article

Save Article

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation