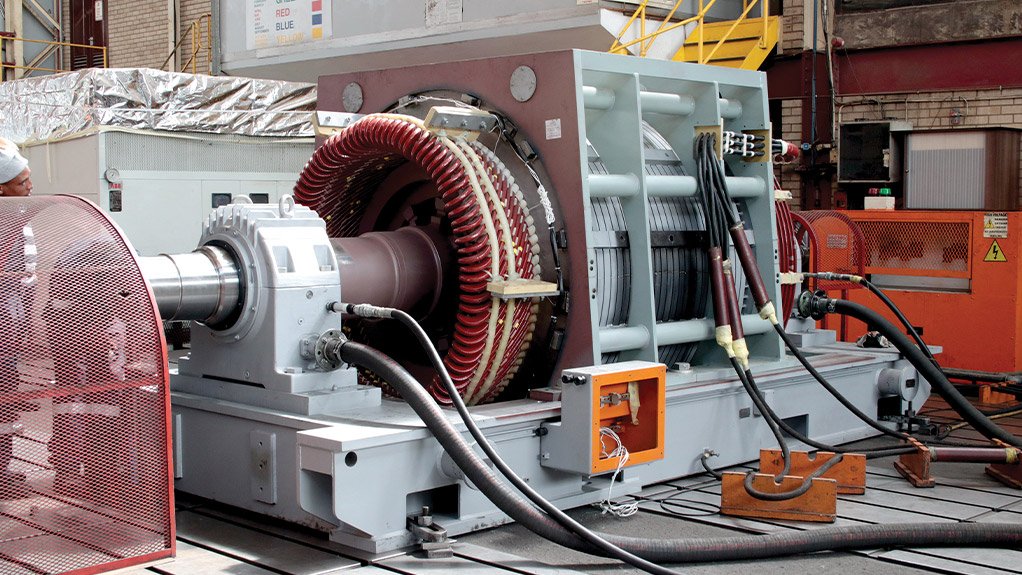

Load testing at DELBA Electrical ensures electrical rotating machine reliability

Electrical rotating machine repairer DELBA Electrical understands that electrical rotating machines are critical components in many industries, driving essential processes and ensuring seamless operations. However, ensuring their reliability under operating conditions is paramount to avoid unexpected failures, costly downtime, and safety risks. Load testing at DELBA Electrical is a vital process in this regard, playing a key role in validating performance and reliability before these machines are returned to service.

Understanding Load Testing

Load testing at DELBA involves operating an electrical rotating machine under controlled conditions to simulate real-world operational demands. During this process, the machine is subjected to incremental loads, imitating the stress it would experience during regular operation. The test evaluates key performance indicators such as efficiency and power output; temperature rise and cooling system effectiveness; and current and voltage stability. These parameters help identify potential issues, ensuring the machine can perform reliably under actual working conditions. There are several benefits of load testing. It verifies operational readiness and provides assurance that the machine is capable of meeting the required performance specifications. It validates repairs, upgrades, or modifications, ensuring the machine is fit for its intended purpose. It also identifies hidden defects. Machines may develop hidden defects during manufacturing, installation, or repair. Load testing exposes these issues, such as insulation weaknesses, imbalances, or mechanical misalignments, before they escalate into major problems. Load testing enhances safety. Operating a machine without testing can pose safety risks to personnel and equipment. Load testing mitigates these risks by identifying potential failure points under controlled conditions, reducing the likelihood of accidents. It extends equipment lifespan by detecting and addressing issues early, thereby helping to prevent excessive wear and tear. This proactive approach enhances the durability of components and extends the overall lifespan of the machine. It also ensures compliance. Many industries and regulatory bodies mandate performance testing to ensure compliance with safety and operational standards. Load testing helps organisations meet these requirements, avoiding penalties and maintaining credibility.

DELBA Electrical’s Load Testing Expertise

DELBA Electrical recognises the critical role load testing plays in ensuring the reliability of electrical rotating machines. Its state-of-the-art test bay is equipped to handle machines of various sizes and capacities, offering comprehensive testing services tailored to diverse industry requirements. DELBA’s process includes dynamic load testing, where it simulates real-world operating conditions to assess performance under varying loads. Data analysis records and analyses performance metrics to pinpoint inefficiencies or vulnerabilities, and it also provides tailored recommendations to address identified issues, optimising machine performance. With decades of experience and a commitment to quality, DELBA Electrical ensures that equipment meets the highest reliability standards before it re-enters service. Load testing is an indispensable process in maintaining the reliability of electrical rotating machines. By verifying operational readiness, identifying hidden defects, enhancing safety, and extending equipment lifespan, it serves as a foundation of effective maintenance strategies. With industry-leading facilities and expertise, DELBA Electrical ensures that machines operate at peak performance, providing the confidence to meet operational demands seamlessly.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation