Major gold producer orders AZMET Cyanide Reduction Process Technology

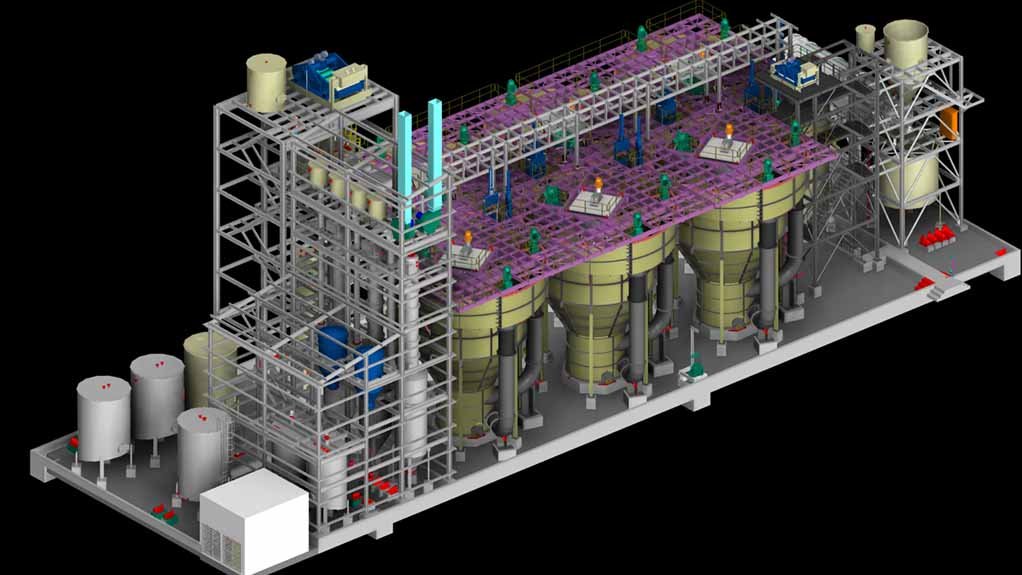

A major gold producer has placed the first order for the award-winning AZMET Cyanide Reduction Process Technology (AZ-CRP) developed by professional engineering design and project management company AZMET Technology & Projects.

Following the order in January, earthworks are under way at the brownfield project in the Democratic Republic of Congo, with construction to be completed in 2023.

The AZ-CRP is designed to realise additional gold recovery from the final tails stream to achieve improved overall plant yield for the client.

Aimed at operational gold producers, AZMET expects to receive more orders for the AZ-CRP in the near future.

“We are confident that it will not be long before the AZ-CRP is implemented as the preferred option of cyanide reduction technology on greenfield projects,” says AZMET director Ruan Kukard.

Last month, AZMET’s AZ-CRP was acknowledged by Mining Equipment Manufacturers of South Africa (Memsa), winning the Innovation in Mineral Processing award at this year’s Innovation Awards.

“To receive recognition for an innovation that is not only our flagship technology but also a game changer in the gold beneficiation market, is a remarkable achievement to be proud of. MEMSA’s focus on the development of mining in South Africa through experience and innovation adds value and credibility to the award,” highlights Kukard.

AZMET knows of no other technology that competes with the AZ-CRP’s additional gold recovery, which it says is comparable with that of a cyanide bottle roll test performed in analytical laboratories.

“There are a few cyanide detox and recovery processes on the market, but they don’t deliver the same return on investment compared with the AZ-CRP. AZMET’s AZ-CRP technology can be installed into the existing tailings discharge stream and requires no dewatering of solids to extract metals and/or cyanide from the slurry stream,” notes Kukard.

The AZ-CRP also reduces and/or eliminates the need for costly cyanide detox reagents and produces cyanide discharge levels well below the regulatory International Cyanide Management Institute requirements while recovering additional gold, he adds.

“The development of the technology was not a sudden inspiration but was achieved through a combination of unrelated processes. In 2014, AZMET started working on a process to recover gold and copper from ore using cyanide. Work on the patented Up-flow reactor started in 2016, where AZMET had to design a vessel for gold adsorption to accommodate various process duty challenges.”

The constant development of the up-flow reactor for the cyanide reduction testwork led to the final version of the AZ-CRP, which uses the AZMET Up-flow reactor to recover additional gold while reducing the cyanide level in the tails stream.

It took seven years for AZMET to finalise its self-funded AZ-CRP and bring it to market.

Getting to this point was challenging and required many onsite lab-scale testwork campaigns followed by pilot plant testing to demonstrate the process and AZMET Up-flow reactor’s benefits, reveals Kukard.

“It is pleasing to see the direct correlation of results achieved in lab-scale testwork (which involved four major gold producers operating in five countries) and pilot plant tests, as this increases the confidence in the technology.”

Comprising 100% local content, the AZ-CRP is manufactured to order, with full project execution taking up to 18 months, depending on the scope of supply.

“AZMET is focused on the development of new process technologies, specifically within the gold industry. With constant rising service and consumable costs, there is an increasing need for alternative process routes with lower operating costs as well as the identification of solutions to protect our environment and promote a safe mining ethos,” emphasises Kukard.

Resultantly, AZMET has focused on developing numerous technologies and products over the past eight years with the aim to improve its clients’ metallurgical process and save them money.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation