Makhado steelmaking hard coking coal project, South Africa – update

Photo by MC Mining

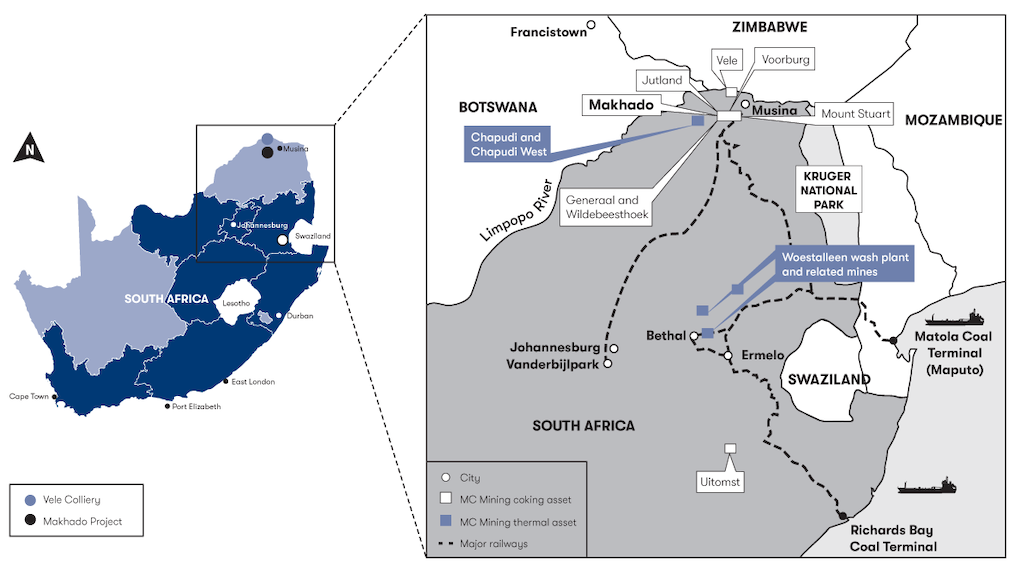

Name of the Project

Makhado steelmaking hard coking coal (HCC) project.

Location

Limpopo, South Africa.

Project Owner/s

MC Mining has 67.3% interest in the Makhado project through its subsidiary Baobab Mining & Exploration, with the Industrial Development Corporation of South Africa owning 6.7%, seven local communities owning 20% and the remaining 6% held by a black economic-empowerment industrialist.

Project Description

Makhado is a fully licensed and shovel-ready steelmaking HCC project. Once developed, it is expected to be the only significant steelmaking HCC mine in the country.

MC Mining’s life-of-mine plan incorporates the exploitation of all portions of the East, Central and West coal deposits that are mineable using surface mining methods.

Run of mine (RoM) production will initially come from the East Pit, with a strike length of 5.5 km, at a width of 400m. Steady-state RoM production is planned at four-million tonnes a year, resulting in sales of 880 000 t/y of primary HCC product, over a 14-year pit life.

The Central and West pits will extend the mine life to 28 years.

Initial HCC production is earmarked for the domestic steel industry, where Makhado coal will have a substantial logistics cost advantage over imports.

Potential Job Creation

The project is expected to create about 650 permanent employment positions.

Net Present Value/Internal Rate of Return

The project has an after-tax net present value, at a 6% discount rate, of R6.8-billion and internal rate of return 37%, with a payback of about 3.5 years.

Capital Expenditure

Peak funding is estimated at R1.8-billion.

Planned Start/End Date

The time to first production is estimated at 18 months.

Latest Developments

MC Mining has started openpit mining.

The associated CHPP was under construction and on schedule for commissioning by year-end, the company said on August 15.

Rapid progress towards coal production is being made on the back of a clean health and safety record, with zero lost-time injuries since work started in November 2024, and full regulatory compliance and progress in line with planned capital expenditure.

The principal mining contractor JCI Mining is now established on site and on schedule with the boxcut. The contractor’s mining fleet comprises five loading excavators and 19 hauling articulated dump trucks, along with a workforce complement that has been augmented to 122 people.

Enprotec, which is building the coal plant on a build, own, operate and transfer contract basis, has completed civil works and has transitioned to erecting structural steel, installing mechanical equipment and platework.

Key mine infrastructure, including bulk power and water supply, a mine access bridge and roads, as well as dirty water containment, are on schedule and in line with the scheduled start of coal production.

Key Contracts, Suppliers and Consultants

Minxcon (bankable feasibility study and potential alternative development scenarios for Makhado); Erudite (detailed planning for a full process design for Makhado); JCI Mining (principal mining contractor); and Enprotec (coal plant construction).

Contact Details for Project Information

MC Mining, tel +27 10 003 8000 or email admin@mcmining.com.

Article Enquiry

Email Article

Save Article

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation