MRC, PMC reach new depths in Lift II ventilation shaft project

LIFE EXTENSION The Palabora copper mine Lift II expansion project is expected to extend the life of mine to at least 2038

COMPLEX OPERATION An excavator busy lashing at the shaft bottom with shaft lining being carried out on the face

Underground mining contractor Murray & Roberts Cementation and its client, copper miner Palabora Mining Company (PMC), celebrate a significant milestone in their partnership as they approach the completion of a notable project that can reshape the future of mining in Phalaborwa, in Limpopo, and extend the life of PMC’s operations beyond 2040.

The PMC Lift II expansion project’s ventilation shaft has reached the 1 100 m mark and underscores a crucial turning point in the pursuit for improved efficiency, safety and long-term sustainability in the mining sector.

Murray & Roberts Cementation senior project manager Fred Durand explains that the PMC Lift II expansion aims to construct a new block cave mine positioned 450 m below Lift I – the existing operational cave – at 1 200 m below the surface.

“As the original Lift I nears the end of its operational life cycle, the development of Lift II becomes imperative to sustain PMC’s mining operations well into the future,” adds PMC senior manager concentrator for underground construction and vent shaft Aidan Schoonbee.

Murray & Roberts Cementation was entrusted with the execution of the shaft sinking, a responsibility it embraced with determination and expertise.

As the project enters the final stages, the implications for PMC’s mining capabilities are substantial. This shaft will alleviate the pressure on the existing ventilation system and provide additional air for production in Lift II. This, in turn, will result in an impressive increase in copper grade, with Lift II boasting 0.65% – a 30% improvement over the nearly depleted Lift I. Moreover, the new shaft, combined with Lift II development, will extend the life of the mine.

The project is now on the cusp of holing into 1 200 m below the surface, with this event scheduled for early January 2024. Following this milestone, the ventilation shaft sinking phase will conclude, and the subsequent steps of removing sinking services, stage suspension to the bank steel, headgear removal, bank steel and stage removal, the placing of ventilation cowling as well as the winder removal will take place in the first quarter of 2024.

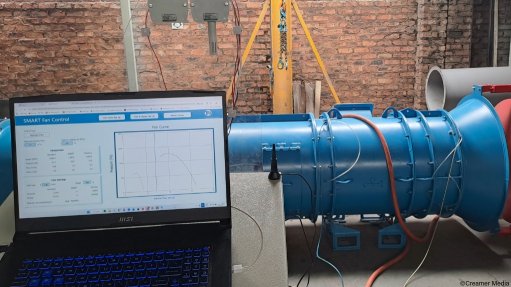

The project’s main highlight will be the construction of a quadfurcated fan station at the top of the upcast shaft, housing four 3 MW fans, operating at 400 m3/s at 5.3 kPa, providing the required 1 200 m3/s of ventilation air. These fans, with their 4-m-diameter impeller, are some of the largest mining fans in operation in South Africa. The fan station, equipped with self-closing doors and ducting, will be a testament to human engineering prowess, constructed using 210 t of steel, in addition to substantial civil and earthworks.

Challenges

The PMC Lift II ventilation shaft project was not without its share of challenges.

The most significant challenge for this project was the increasing virgin rock temperature rising from 49.7 °C to 58.6 °C between Lift I and Lift II, coupled with the Phalaborwa area’s hot and humid climate, Durand points out.

To meet the demands for ventilation and cooling, PMC invested in a comprehensive infrastructure upgrade, including new upcast fans, refrigeration plants, raisebored vent passes, and a new blind sink vent shaft from the surface to Lift I ventilation level.

The unique ground conditions, including Micaceous Pyroxenite rock, presented difficulties. Large rocks in the shaft bottom after blasting, necessitated innovative solutions. A hydraulic rock breaker, coupled with an excavator, reduced the time required to break and remove these obstacles, resulting in a 70% time-saving.

Fragmentation was another challenge, owing to the distinct ground characteristics, consequently leading to multiple attempts to refine drilling designs and explosive types in collaboration with the company’s explosives suppliers. The eventual breakthrough came with a winning design and explosive type tailored to the rock hardness.

Meanwhile, the Covid-19 pandemic was an unexpected hurdle that affected the project’s timeline. PMC and Murray & Roberts Cementation collaborated closely during this trying period, amending contract clauses to ensure the project’s progress while adhering to safety measures.

Success and Collaboration

The completion of the PMC Lift II ventilation shaft project represents a landmark achievement for Murray & Roberts Cementation and PMC. “For PMC, it signifies an extension of its mining operations for another two decades, securing jobs and enhancing the region’s economy,” states Schoonbee.

“For Murray & Roberts Cementation, it exemplifies the power of innovation, client support and a committed team to execute projects without compromising employee safety,” says Durand.

The collaboration between the companies was a cornerstone of the project’s success, and is evident in various aspects, most notably that safety matters were jointly managed.

“Planning and design were collaborative efforts, while decision-making, including the mining method, was based on input from both parties,” notes Durand.

PMC provided utilities and services to the site, where the company’s scope was expanded to include compressed air supply. Innovative thinking and collaboration allowed the renegotiation of selected key performance indicators during the Covid-19 pandemic and when encountering bad ground.

“The support and involvement of PMC as a stakeholder played a pivotal role in the morale and attitude of the shaft sinking crew,” Durand states.

Murray & Roberts Cementation’s expertise in handling complex mining projects, exemplified by the PMC Lift II ventilation shaft project, underpins its status as a leading multinational engineering and construction group in Southern Africa.

Its commitment to sustainability, engineering, procurement, construction, commissioning, operations and maintenance solutions ensures the success of projects that enhance the mining industry and the future of Phalaborwa.

The project represents an impressive feat of collaboration, innovation and technical expertise, setting a new standard for mining operations in the region. It is testament to what can be achieved when industry leaders unite in pursuit of a common goal. As the project nears completion, the horizon for Phalaborwa’s mining future is looking brighter than ever.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation