Nearly 30 years of ‘Tru-Trac moment’ for conveyor users

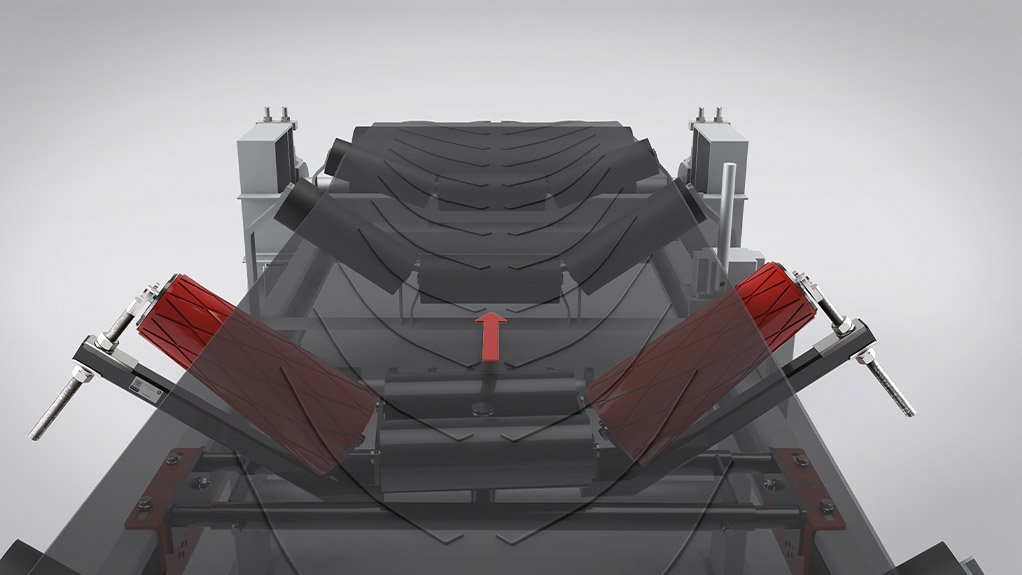

The patented Tru-Trac Taper Trough Tracker offers the ultimate in tracking performance on the load-carrying side of conveyor belts

Tru-Trac have been acknowledged worldwide as the most reliable and effective conveyor belt tracking system

Tru-Trac has evolved into a full service conveyor solutions business, and the company offers valuable support to customers

The Tru-Trac tracker offers a long term solution that corrects belt misalignment

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

With belt misalignment remaining the biggest headache for conveyor system operators across a variety of bulk material handling industries, Tru-Trac has evolved from this valuable niche into a full service conveyor solutions business.

Having patented and commercialised its belt tracker back in 1996, Tru-Trac has leveraged its engineering expertise and market knowledge into a comprehensive range of conveyor solutions – with a global sales and installation network. There remains, however, a ‘magic’ at the core of the business which continues to surprise and delight customers: the company’s deep understanding and expertise of belt misalignment solutions - belt trackers.

Shaun Blumberg, COO of Tru-Trac Rollers, highlights the serious disruption that belt misalignment on a conveyor can cause. The impact includes spillage, belt edge damage, structural harm, increased power consumption and increased labour costs. Ultimately, this leads to lost production, higher operating costs and even safety hazards.

From its world class local manufacturing base in South Africa, Tru-Trac has grown to serve markets nationwide and abroad – including some of the most sizeable equipment in operation. One of the world’s largest stacker reclaimers, which serves the coal sector in Germany, also experienced a Tru-Trac moment, according to Jonathan Rogoff, CEO of Tru-Trac.

“They were having significant challenges with belt misalignment– and told us they never had a belt tracker last more than a week,” explains Rogoff. “When we presented our proposed solution, they were sceptical – thinking we were either over-confident or naive.”

Leveraging decades of application data and its in-house engineering expertise, Tru-Trac enhanced its heavy-duty dual-return tracker into an extra heavy-duty (EXHD) model specifically tailored for this customer's needs.

“This was a demanding application with the 2,300 mm wide belt running at 9,6 metres per second – close to the speed of some of the fastest belts in the world,” he says. “A year later, our product was still working well, leading the customer to standardise on this Tru-Trac solution.”

Closer to home, a mining company in Rustenburg recently had their production halted for two days after successive failures of numerous belt tracking products. After a site visit to assess the situation, Tru-Trac returned the following day with two of its belt trackers – to replace the five installed competitor products.

“Within 20 seconds, the belt centralised and the problem was solved,” says Rogoff. “Initially, our customer could not believe what he was seeing and was convinced the old problem would return when material was loaded. However, the belt remained true under full load, as we had predicted.”

Blumberg points out that there has been significant growth in the business over recent years, and the company has expanded its local manufacturing to punch above its weight on the global stage. In fact, within the industry, the brand has become synonymous with its product, to the extent that professionals often refer to any conveyor belt trackers as 'Tru-Trackers'

After the worldwide success of its tracking solutions, it made sense to leverage its trusted brand and expertise by diversifying into complementary conveyor solutions. Through its existing partnerships with international conveyor distributors, Tru-Trac began importing well recognised brands to augment its range. This includes belt scrapers and skirting rubbers as well as impact beds.

“This led to us building our own service teams to provide installation and maintenance support for customers, as we were now dealing with equipment that needed servicing,” says Rogoff. “The beauty of our belt trackers is that they are essentially ‘fit and forget’ solutions that need very little attention during their lifecycle.”

Today, there are about 50 Tru-Trac service teams working across South Africa and into the rest of Africa, to support customers. With this growth came an expansion of in-house sales teams, who work from branches in the main mining regions in South Africa and Africa

“This gave us more control over our own destiny allowing us to develop skilled customer-centric teams to service customers as a complete provider of mechanical solutions and services on conveyor systems,” he says.

Tru-Trac also now supplies its world class conveyor solutions to over 80 countries globally, including almost every mining country. At its world class facility in Centurion near Pretoria, there are now over 100 employees on the manufacturing side alone.

The company’s in-house engineering and R&D capabilities have significantly expanded, with the size of its R&D department increasing fivefold over the past two years. This growth has enhanced Tru-Trac’s engineering and design capabilities, which include custom design and rapid prototyping, showcasing the company’s commitment to innovation and tailored conveyor system solutions.

“One of the rewarding parts of our work is that we provide conveyor solutions that really do deliver what customers require,” concludes Rogoff. “We still regularly have customers whose jaws drop in disbelief when we solve challenges which they have unsuccessfully been grappling with for years.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation