New coagulant mitigates challenges of colloidal silica

ADAPTABLE SOLUTION The chemistry behind the DEHSCOFIXSC12 is adaptable for other acid leach-based processes by improving phase separation, while reducing silica interference in ion exchange and solvent extraction

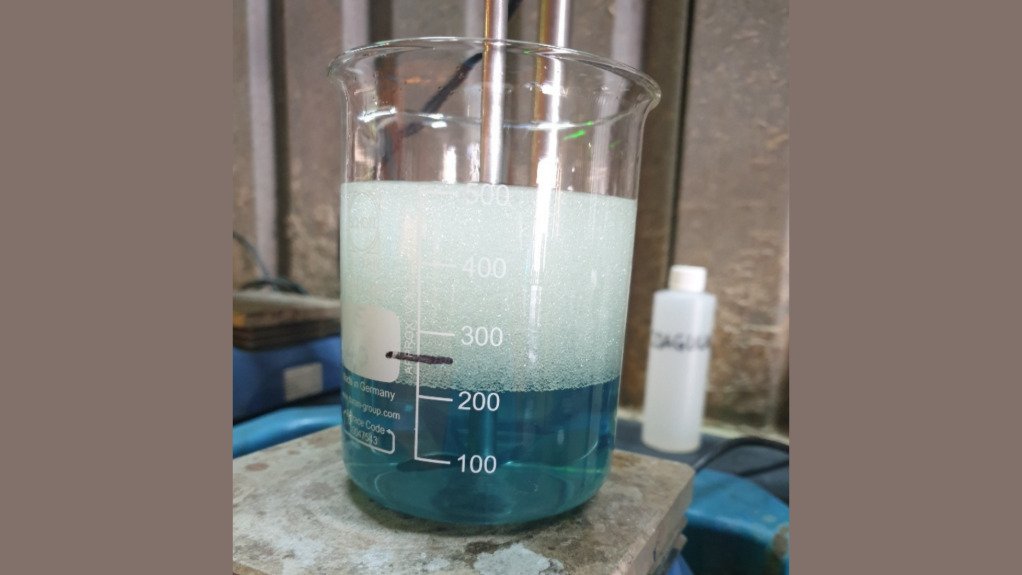

COLLOID DESTABILISATION Designed to remove colloid silica by promoting coagulation of particles, the DEHSCOFIXSC12 binds to the particle surface and destabilises the colloid, so that the coagulated particles can be removed from the solution

Following challenges in the mining sector caused by colloidal silica in copper and cobalt leaching, mining chemicals supplier BME Metallurgy has succeeded in the development and application of an innovative solution that is suitable for use in such applications and which promises potential in other commodity segments.

Colloidal silica can cause serious operational issues in hydrometallurgical plants, particularly in solvent extraction, notes BME Metallurgy business development manager Daniel Verwey.

“For many years, process plants have grappled with the impacts of silica, a highly prevalent gangue mineral that is leached into solution during acid leaching of valuable metals,” he states.

Depending on its quantity, colloidal silica could undermine the efficiency of the extraction process, potentially to the extent of shutting down the process, explains Verwey.

As such, in partnership with specialty chemical company Innospec – which provided a specialised coagulant called DEHSCOFIXSC12 – BME Metallurgy assisted its customer, base metals miner MMG, to apply this novel solution at its Kinsevere mine, in the Democratic Republic of Congo.

“The product is designed to remove colloidal silica by promoting coagulation of particles. It binds to the particle surface and destabilises the colloid, so that the coagulated particles can be flocculated and removed from the solution,” he explains.

As a result, the removal of the colloidal silica in Kinsevere’s solvent extraction plant delivered many important benefits, including a reduction in total suspended solids, in crud formation and in entrainment.

Importantly, there was increased pregnant leach solution throughput, thereby allowing improved copper production and cathode quality.

“The key improvement was seen on the throughput, where the mine managed to increase throughput by approximately 20% by eliminating the need to operate at high organic to aqueous ratios,” highlights Verwey.

Additional benefits were seen in reduced total suspended solids in the thickeners and lower organic entrainment losses, which translated into measurable cost savings and operational reliability.

Verwey explains that the Kinsevere project demanded considerable laboratory testwork conducted with DEHSCOFIXSC12, which showed not only that it could remove a significant proportion of colloidal silica from the pregnant leach solution but that it could also improve phase disengagement time, as well as eliminate stable emulsion formation.

This was followed by plant trials, where these results were confirmed.

“The ability to mitigate colloidal silica challenges unlocks greater process stability and predictability, which is critical for African copper and cobalt producers operating under tight margins,” he says.

Improved metal recovery and reduced downtime enhance profitability and sustainability, while enabling operations to increase resource use and difficult-to-treat ores, as well as extend asset life, states Verwey.

Process Adaptability

In its full plant implementation of the DEHSCOFIXSC12, the Kinsevere mine used the coagulant to dose the leach discharge slurry, resulting in the silica in pregnant leach solution being reduced from an average of 1 400 parts per million (ppm) to below 500 ppm.

This resulted in the solvent extraction plant immediately recovering its stability, in addition to resuming operations at full capacity, thereby bringing production back to historical levels and improving the quality of its copper cathodes, states Verwey.

The chemistry behind the DEHSCOFIXSC12 is adaptable to other leach-based processes, including uranium, by improving phase separation while reducing silica interference in ion exchange and solvent extraction, he notes.

This, highlights Verwey, could result in the DEHSCOFIXSC12 enabling higher recovery rates and safer, more efficient uranium processing.

“This opens opportunities for new project designs and retrofits, supporting Africa’s diversification into critical minerals for nuclear energy and advanced technologies,” he says.

Additionally, Verwey highlights that solutions such as the DEHSCOFIXSC12 could reduce operational bottlenecks, improve recovery and lower costs, thereby making African projects more attractive to investors.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation