New grader range breaking ground in S Africa

Bell Equipment original-equipment manufacturer product manager Jeremiah Mokhomo discusses the launch of the new Bell motor grader range

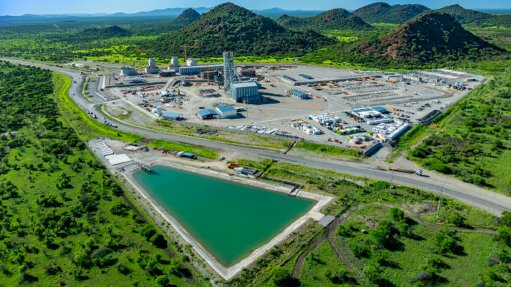

AT SURFACE LEVEL The new motor grader launched by Bell Equipment is suited to the surface mining, agricultural and construction sectors

After a successful launch at Bauma 2025, held in April in Munich, Germany, South African earthmoving equipment manufacturer and supplier Bell Equipment introduced a new range of motor graders to the South African market.

The launch, held earlier this month in Ballito, KwaZulu-Natal, targeted not only the earthmoving and surface mining sectors, but also clients in the construction and agricultural sectors.

The grader will be available in three configurations: the G140, G160 and G200, reveals Bell Equipment original-equipment manufacturer (OEM) product manager Jeremiah Mokhomo.

At the launch event, Mokhomo explained that the G140 is ideal for maintenance and light to medium construction tasks, while the G160 has been designed for heavy construction work with increased power and higher performance. The G200, meanwhile, is optimal for heavy mining applications and bulk earthworks with even further capacity to take on bigger tasks.

The launch event also provided the opportunity for grader operators present to sample the equipment, with Mokhomo emphasising that the operators play a significant role in influencing which grade of grader to purchase for specific tasks.

Demonstrating the ease of operation of the machines provides potential buyers with confidence that their operators can adapt to the new equipment with minimal or no additional training, he says.

“This is why we continually engage with operators and designers to ensure our machines are both functional and comfortable,” says Mokhomo.

Built Tough in South Africa

Developed, designed and made locally, Mokhomo says Bell graders will enhance driver awareness and ensure pedestrian safety through the equipment’s integrated third-party L9 pedestrian detection systems, while collision avoidance systems employ an ISO 21815-2 interface for additional safety measures.

“Safety is not an optional extra or bonus feature; we have manufactured the graders to include these systems automatically,” he notes, adding that L9 represents the highest level of automatic intervention available, to date.

In addition, the graders are designed to be compatible across the most common operating systems and are capable of integration with a variety of third-party technologies, including 2D and 3D grading systems.

“This versatility allows customers to connect the grader to their preferred precision grading solutions, enabling high levels of grading accuracy and operational efficiency,” says Mokhomo.

Further, both operator and machine performance can be monitored and managed under Bell Equipment’s in-house telematics system, Bell Fleetm@tic.

“The machine’s operational data is collected, processed and compiled into valuable production and performance statistics, which are accessible through automated reports or the Fleetm@tic website,” he says.

First Grade Grader

Bell’s range of motor graders is engineered to excel in demanding conditions and offers a robust frame, high-performance hydraulics and advanced technology for improved control. These features, says Mokhomo, serve to improve grading efficiency on any terrain.

Further, several new additions and technologies make Bell’s graders “true competitors” in the sector, including the range’s shuttle shift feature on the transmission controls, with the addition of cruise control to maintain a constant travel speed to reduce operator fatigue, especially during long passes, he points out.

An auto disengagement of the diff lock and six-wheel drive ensures improved traction and provides protection to the machine when operators are unable to secure the vehicle.

A large cab, which is protected from falling objects and roll-over incidents, provides enhanced operator protection and enables unobstructed visibility, while climate control systems further add to operator comfort in harsh operating environments.

The onboard seven-inch colour display, explains Mokhomo, is crucial to monitoring machine operation, including diagnostics and can be easily navigated using the automotive mouse, known as the B-drive.

The graders also include intuitive controls, which, when engaged, enforce speed control, promoting optimal grading performance.

In terms of servicing and maintenance, he points out that Bell’s graders have all filters and oil sample points conveniently grouped on one side of the machine for easy access from ground level through a single door, which reduces maintenance time and effort.

Further, the grader’s cooling radiators are housed in a box design, ensuring easy cleaning and enhanced cooling efficiency, with no stacked configurations.

As for operational control, the grader’s two position drawbars allow operators to adjust the drawbar height depending on the tyre size, assuring the drawbar remains level, preventing the mouldboard corners from digging or lifting as the operator rotates the circle during grading.

“These machines are built in Africa, for Africa, and we are confident that we will set a new benchmark in performance, reliability and operator satisfaction across the region,” concludes Mokhomo.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation