New pumps range lowers costs, enhances performance at integrated ferrochrome producer

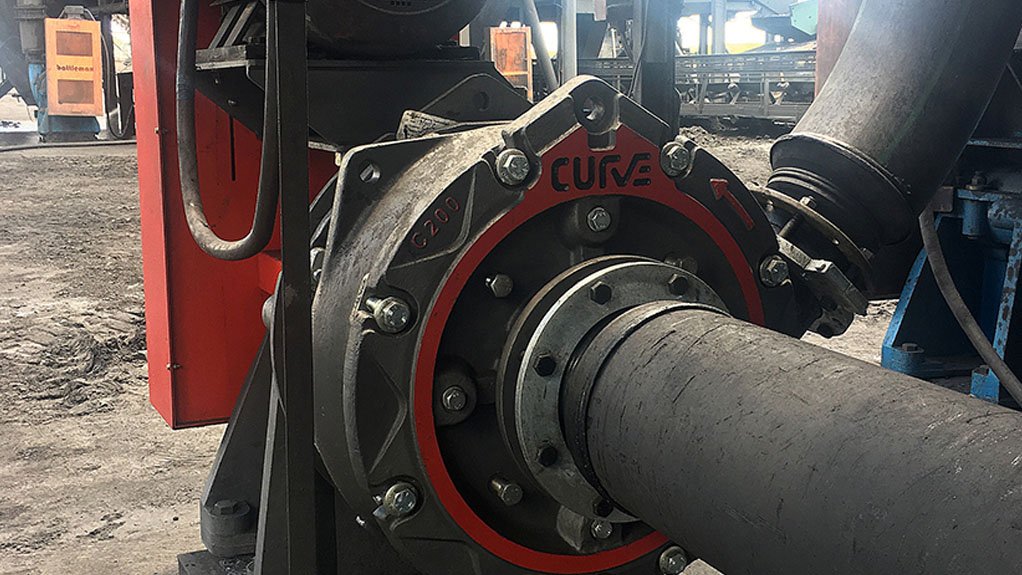

CURVE PUMP The Curve pumps installed at Hernic Ferrochrome operate 50% slower than the previous pumps, lowering costs while not limiting performance

Following the launch of heavy-duty pump solutions company Pump and Abrasion Technologies’ (PAT’s) new Curve range of pumps in September 2016, a North West-based ferrochrome producer has installed the new Curve series pumps at its plant.

The ferrochrome producer now plans to replace all its pumps at one of its plants with the Curve range. The conversion project started with the installation of the first pump in November 2016.

PAT sales director James Pienaar says the ferrochrome-producer installation was, in effect, the “first true test” of the Curve S150 pump. “The changeover of all existing pumps at the customer’s processing plant to the Curve range is a process that takes time, but we are . . . close to [having] ten Curve pumps . . . installed and operating at that specific plant.”

The Curve S150 model offers several innovative features that make it the ideal choice for the ferrochrome customer’s operational needs. These features include fully profiled impeller vanes, an adjustable throatbush, an enhanced cutwater profile and a clip-in suction joint.

Sealing performance and pump life have been enhanced by a larger diameter expeller and high chrome-shaft sleeve and lantern ring. The Curve S150 also features a discharge piece designed to eliminate the need to remove the discharge pipe during routine maintenance.

To date, the Curve pumps at this processing plant operation have produced a 73% reduction in downtime, as they are opened only every third maintenance cycle, owing to its longer wear life. Maintenance time and cost reduction were measured in comparison to the wear life and required maintenance of the previously installed pumps.

Further, the Curve pumps’ encapsulated one-piece volute liner reduce opening and closing time by 80%, eye bolts allow for safe removal of the casing, the casing assembly is a balanced load for safe handling, and the discharge pipe no longer needs to be removed when opening the pump because of the newly designed discharge piece.

Pienaar adds that the Curve pumps also reduced electricity consumption. “An 8% power reduction was reported . . . through the improved impeller and volute profile design. Slurry flows through the pump in a more natural flow pattern.”

A 52% reduction in total cost of ownership was also reported. These results prove the Curve range’s ability to outperform older technology pumps on the market, he says, adding that the basic specifications of the previous pump and the Curve pump in the trial application were virtually the same.

Both pumps have rubber liners and a 35% chrome impeller. In terms of expected performance, both pumps offer 38 ℓ/s. The duty covered by both pumps is the transfer to plant, with a particle size of 80% less than 1.5 mm. However, the Curve S150 operates 50% slower in this application, thereby significantly reducing wear and power consumption.

Article Enquiry

Email Article

Save Article

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation