Oil-lubricated rolling bearings improve reliability of electric motors

HIGHLY ROBUST The ORLB’s enclosed design with oil and labyrinth seals provides reliable protection against dirt, dust and moisture

NO LIMITATIONS In applications with large variable speed ranges, the OLRB, unlike sleeve bearings, allows for an uninterrupted speed control range

Industrial downtime is often caused by defective bearings. Studies show that about 80% of all bearing damage is owing to insufficient or incorrect lubrication. This is associated with overheating, wear and costly production losses, says electric motors and large drive systems provider Innomotics.

The most common sources of error include incorrect lubricant quantities – whether owing to over- or under-greasing. Contamination of grease by dust, moisture, or other environmental factors is equally critical. Another risk factor is the failure to adhere to the relubrication intervals prescribed by the motor manufacturer. Mixing different greases or failures of automatic relubrication systems could also lead to premature bearing failures, elaborates the company.

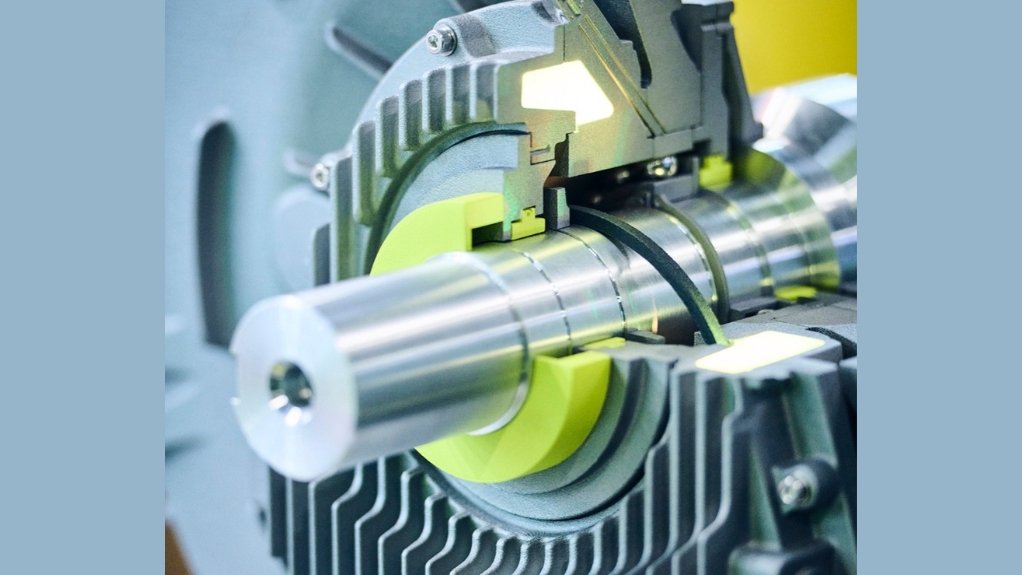

With the oil-lubricated rolling bearing (OLRB), Innomotics has developed a patented solution for high-voltage motors that eliminates these risks. Instead of grease, an oil ring ensures that the bearing is continuously lubricated correctly. The results: lower operating temperatures, higher reliability and significantly less maintenance.

“While grease-lubricated bearings need to be relubricated after just 1 400 to 2 500 operating hours, an oil change every two years is sufficient for the OLRB, or possibly even longer intervals upon request. In addition to its technical advantages, the OLRB is also economically compelling. Depending on the installation situation and accessibility, the cost of relubricating grease-lubricated bearings is about €1 500 to €2 000 per procedure. Within two years, eight to 12 relubrication intervals result in total costs of about €12 000 (based on a conservative estimate for eight intervals of €1 500 each). With the OLRB, only one oil change for about €1 500 is required in the same period. This results in savings for the operator of v about €5 000 a year. Based on current costs and sales prices, the investment pays for itself within a year – a clear economic advantage over conventional bearing solutions,” explains Innomotics.

Besides its cost-effectiveness and efficiency, the OLRB is highly robust. The enclosed design with oil and labyrinth seals provides reliable protection against dirt, dust and moisture. With a protection class up to IP56, it is ready for use even in the harshest industrial environments. It also features a wide temperature range from –20 °C to 60 °C and is suitable for explosion-proof motors.

Compared with sleeve bearings, the OLRB is more compact and cost-effective, and does not require external oil lubrication, highlights Innomotics. In applications with large variable speed ranges, the OLRB, unlike sleeve bearings, allows for an uninterrupted speed control range from 0 rpm up to the maximum operating speed.

The OLRB is setting a new standard in motor technology, says the company.

“The innovative, patented solution combines the advantages of sleeve and rolling bearings in a compact design, reduces downtime risks and extends the service life of electric motors – all while providing significant cost benefits for the operator.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation