Plastic valves distributor stakes claim in SA market

MANY BENEFITS Plastic valves do not corrode, pit or rust internally and externally

Local flow and measurement specialist Instru-Serve in August began distributing a range of plastic valves, manufactured by piping systems manufacturer Georg Fischer, to the South African market.

Instru-Serve sales and project manager Kevin Lindsay tells Engineering News that the company is confident that it can gain significant market share, as it will enter into the areas of the market where plastic valves are not currently used.

The company is aiming to promote the Georg Fischer range among industrial users in the construction, chemicals and mining industries, as well as in municipalities, he adds.

Lindsay notes that, while the plastic-piping and valves market in South Africa is fairly well established, with only a few large players in the industry, the quality of the products they supply cannot compete with the quality of the products manufactured by Georg Fischer, though they largely do not need to because the companies are operating in different sectors of the market.

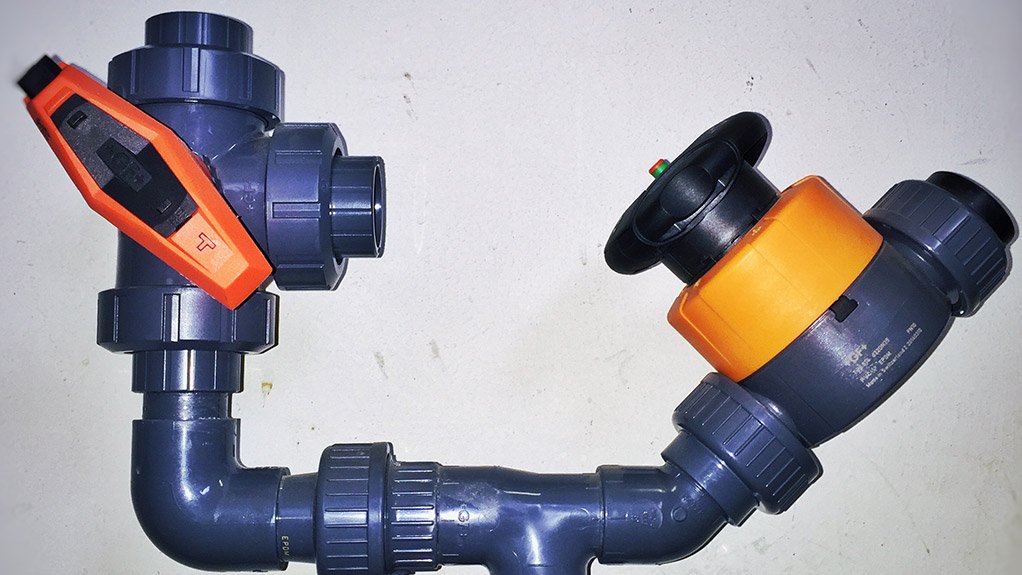

Ball Valves

Lindsay tells Engineering News that, thus far, the Georg Fischer 546 ball valve has proved the most popular among South African clients.

It is a high-quality ball valve with a one-piece moulded valve body, available in a variety of different plastic types and sizes up to DN100, he says.

These ball valves can be connected to existing pipes using a variety of connection options such as solvent cement sockets, backing flanges, fixed flanges and fusion sockets.

The ball and diaphragm valve bodies are one-piece moulded units, with multiple seals contained within the valve, which ensure that there are no leaks when the valves is under pressure.

Within the ball valves range, there are also more basic ball valves for agricultural use, as well as three-way ball valves, used in mixing and flow-diverting processes.

The 546 and three-way ball valves can easily be electrically or pneumatically actuated by removing the handle and installing the actuator in its place. Not many other types of valves can be retrofitted this easily, Lindsay states.

The 546 can be serviced using the valve lever, which detaches and slots into the valve face, enabling the user to remove and replace components such as seals and ball units.

Meanwhile, the Georg Fischer range of valves also includes sprung and unsprung check valves, pressure-retaining and pressure-reducing valves, bleed valves and the full range of fittings, accessories and tools – including fusion- welding machines – required for a complete installation. Instru-Serve also provides after-sales service on behalf of Georg Fischer.

Georg Fischer valves are available in a variety of plastic types; once the plastic type has been chosen, the connection fittings can be selected, along with the seal type.

All individual components of the valves are also separately replaceable, so the life-cycle costs of the valves are significantly reduced, compared with the costs of steel valves.

Steel Dominant

Lindsay notes that, although South African valve consumers tend to favour steel for industrial applications because it is supposedly stronger, this is not necessarily the case. He argues that plastic is just as strong and also significantly lighter than steel, allowing for lower logistics costs, as well as quicker and easier installations.

In most instances, plastic valves are initially marginally more expensive. However, they come with many advantages that justify the initial higher price and, as long as the correct material type is selected for the valve body and seals, plastic valves generally last significantly longer than steel valves, Lindsay explains.

He further notes that plastic valves are significantly easier to open, as steel valves stick and require a great deal of force to open. Therefore, plastic valves could be considered a longer-lasting and less energy-intensive option for actuators.

Moreover, plastic does not corrode, pit or rust internally and externally. It also does not require specialist fitting skills and is more resilient to long-term wear and tear.

In terms of manufacturing, steel valves are forged or cast in sections and then joined together, depending on the type of valve. To an extent, this process is accurate but cannot achieve the low tolerances achieved during the manufacturing of plastic valves, Lindsay maintains.

All Georg Fischer valve bodies are injection-moulded using high-tech machinery and quality-control procedures to create a one-piece moulded valve body.

All valves are then pressure-tested during production to ensure that there are no leaks in the one-piece mould and the completed valve. Valves that do not pass the tests are discarded.

Meanwhile, Lindsay notes that Georg Fischer has developed an online carbon dioxide calculator that gauges the environmental impact of plastic piping valves, compared with the impact of steel valves, with the calculator having showed that replacing stainless steel with plastic yields the highest carbon saving.

New Partnership

Instru-Serve acquired distribution rights for the Georg Fischer range in October 2014 and immediately began distributing Georg Fischer measurement and control products.

The Georg Fischer range comprises more than 60 000 products, enabling individual solutions for a large range of demanding applications and processes in a variety of sectors, states Lindsay.

Companies that have used Georg Fischer plastic valves include semi-conductor manufacturing company Intel and shipbuilder STX France.

Lindsay says plastic valves were suitable for Intel because the manufacture of semiconductors takes place in highly specialised faci- lities that use strictly controlled cleanroom production areas. Therefore, Georg Fischer sup- plies Intel’s global production facilities with a portfolio of high-purity plastic systems for the safe and reliable conveyance of critical processing fluids used in semiconductor production.

Meanwhile, Georg Fischer was recently awarded a contract by STX France to equip three new cruise liners with corrosion-free plastic piping and valve systems. Factors that contributed to the company being selected include its comprehensive maintenance offering for on-board piping systems at major ports in the US, Europe and Asia, as well as its experience in the shipbuilding industry.

Lindsay notes that innovative Georg Fischer piping and valve technologies are being instal- led on the largest cruisers worldwide.

Instru-Serve aims to bring the Georg Fischer brand to market in South Africa and to create awareness among whoever can benefit from the product, concludes Lindsay.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation