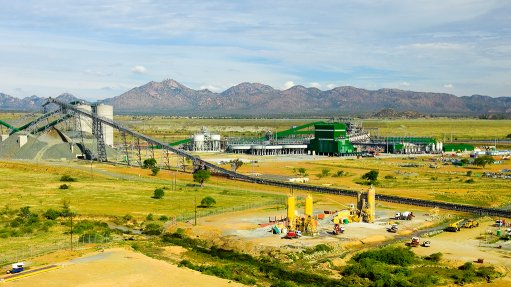

Pre-engineering is key to Superior’s new modular platform systems

This article has been supplied.

Superior Industries, Inc., a U.S. based manufacturer and global supplier of bulk material processing and handling systems, is excited to offer a new series of modular plants for aggregate crushing, sorting, sizing and washing applications. Known as Fusion™ Modular Platforms, these pre-engineered, ready-to-build systems still allow customization to achieve best performance at each jobsite.

“Our plant designs are scalable and easily expand with a developing customer site,” says Mark Crooks, product manager at Superior Industries. “Producers can quickly expand capabilities as finances allow, application needs change and as their market develops.”

Today, Superior has pre-engineered a series of plant packages and is working to design more for its catalog. Some examples include jaw, cone and impact crushing platforms, horizontal screening platforms with two, three and four deck models, plus a group of traditional washing and modern low water washing platforms.

“Overwhelmingly, our customers said they want scalability and flexibility in these modular offerings,” says Crooks. “Therefore, as we developed our strategy, we ensured flexibility from top to bottom, convenient installation or dismantling and seamless integration with Superior crushing, screening, washing and conveying machinery.”

Fusion Modular Platform systems are pre-engineered for earlier commissioning, more cost-effective than design-build plants, incorporate well into existing plants and utilize creative packaging to limit the number of flatbeds or shipping containers needed for transportation.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation