Process headaches? Let VEGA’s smart sensors do the thinking

This article has been supplied.

(Virtual showroom) A petroleum wholesaler based in south-central Michigan has been steadily expanding its operations for over 80 years. Now in its fourth generation, the company provides heating solutions, fuels, commercial oils, and industrial lubricants to clients in Michigan, Indiana, and Ohio. Ensuring accurate management of product distribution across multiple locations is crucial. Transport trucks regularly refill and distribute items from 18 bulk storage tanks located at three facilities, while suppliers replenish these tanks to maintain smooth operations.

Beyond Basic Safety Requirements

Safety is the top priority when dealing with petroleum products. Spills are costly due to lost product and EPA cleanup requirements. To ensure safety, the company installed high-level limit switches on bulk storage tanks. A failure in the point-level switch resulted in a significant disruption, leading to both the loss of a substantial quantity of product and the need for extensive cleanup efforts. This malfunction not only impacted the operational efficiency but also created a challenging situation that demanded immediate attention to restore normalcy. Instead of “just replacing” it, the company decided to enhance its system with continuous level measurement, visual feedback, audible alarms and remote monitoring integration.

Partnering with VEGA for a Complete Solution

The petroleum wholesaler researched to find a comprehensive solution and came across VEGA. After a brief phone call, they were introduced to a local VEGA representative who promptly visited, listened to their requirements, and provided an on-site demonstration of a potential solution.

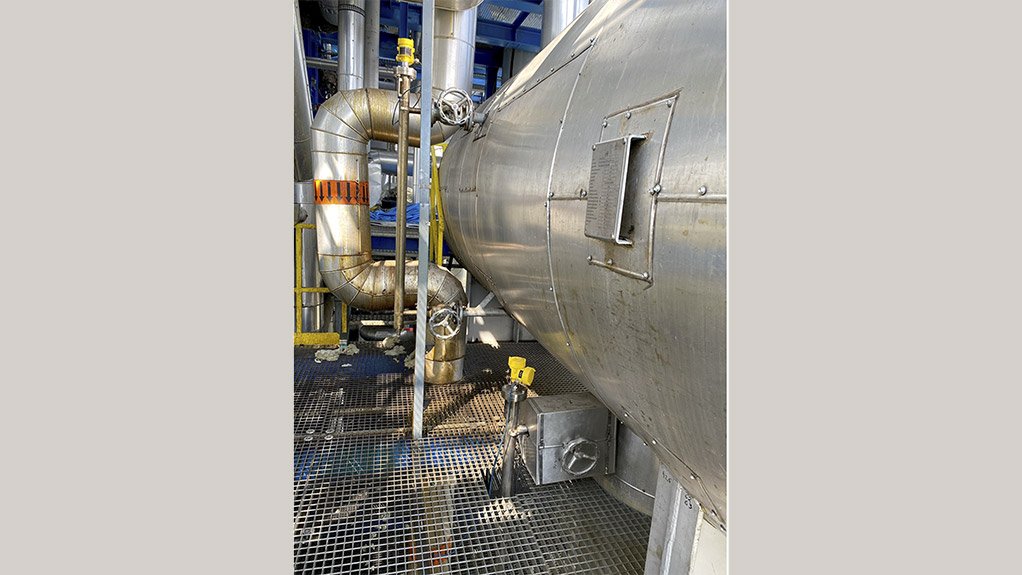

Following additional discussions and further research, the wholesaler opted for non-contact 80 GHz radar combined with an inventory management and alarm system. Specifically, they purchased 18 VEGAPULS C 21 radar sensors and three VCCS13e central visualisation cabinets – one for each of their locations.

The VEGAPULS C21 offers a non-contact, maintenance-free measurement, eliminating the need to clean the sensor. The C21 radar level sensor utilises 80 GHz technology for precise and dependable measurements, while the 80 GHz frequency allows for a more focused beam angle, ultimately resulting in a stronger signal return, even with fluids that have poor reflective qualities.

The VCCS13e serves various functions in inventory management applications, including the ability to power up to 30 connected devices. Its large touchscreen displays local visualisations of level measurements for up to 10 vessels simultaneously. Furthermore, the VCCS13e employs an external alarm light and horn to alert users to up to four different alarm points per sensor.

Improved Safety and a Smarter System

VEGA assisted in commissioning the radars and an inventory management and alarm system at each of their three sites. With the new, more reliable measurement system implemented, the company has enhanced safety and efficiency in their operations. The company has not only invested in advanced technology but has also formed a strategic partnership with VEGA. This collaboration is essential, as VEGA has a deep understanding of the company's specific needs and provides continuous support for all aspects of level measurement and inventory management.

When it comes to process control, simplicity and precision go hand in hand. VEGA’s smart sensors are designed to simplify measurement, providing clear and reliable data where and when it matters. Process headaches? Let VEGA’s smart sensors do the thinking—so you can focus on performance, not problems. Maximum control. Minimal hassle.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation