Pump range accommodates midtier miners’ evolving needs

DIREN LALLA FLSmidth is a strategic technology partner, and its technical expertise is sought after by members of the mining industry

HERMAN BRITZ As mid-tier miners ramp up or wind down production, it is vital that the correct pump size be employed to deliver the most efficient and cost-effective outcome

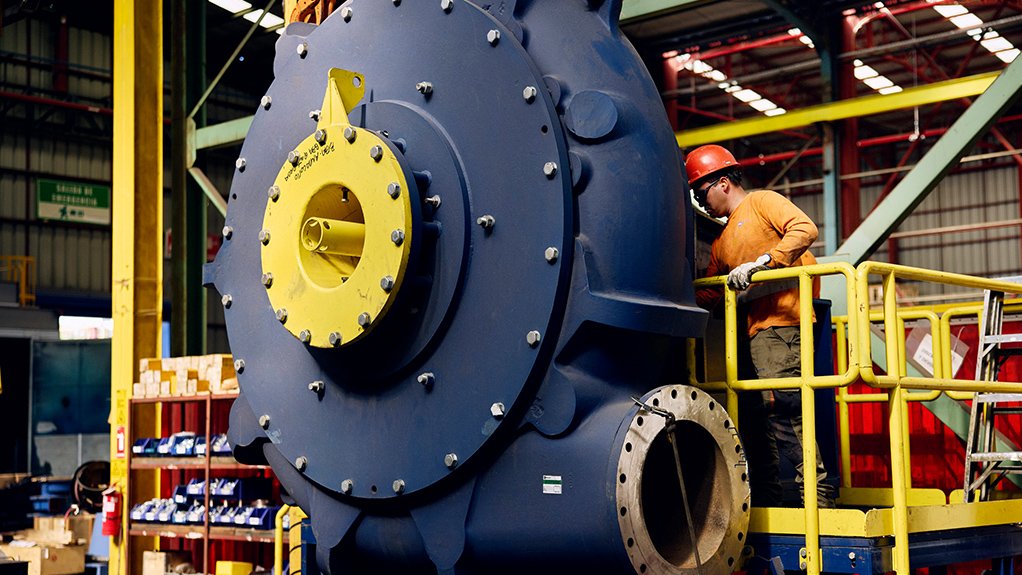

THE FLSMIDTH STORMILL FACILITY FLSmidth has digitalised its processes and, using predictive analysis, endeavours to have the right components ready to ship to its customers at the right time

PROMOTING UPTIME The KREBS quick release system for pump rebuilds reduces downtime by up to 50%

There is a sweet spot when selecting the correct pump for a specific application and the KREBS pump range from minerals processing and materials handling technology and systems supplier FLSmidth aims to offer a solution for every stage of a midtier mining operation’s life cycle.

As midtier miners ramp up or wind down production, it is vital that the correct pump size be employed to deliver the most efficient and cost-effective outcome, says FLSmidth regional product line manager for pumps Herman Britz.

“A pump needs to run at a certain efficiency point to retain its effectiveness. If you specify a pump according to the production capacity that is expected six or 12 months down the line, you start losing efficiency.”

Britz explains that using a pump outside the original selected range will have a detrimental effect on the life of the pump, cancelling out the cost saving that potentially influenced the buyer’s initial purchasing decision.

“To benefit from an increased pump life and eliminate unnecessary maintenance costs, it is more cost effective to select the right pump for your current application and upgrade your pump as you increase production capacity.”

In saying this, FLSmidth also endeavours to ensure that a midtier miner’s pump selection can be easily upgraded, explains FLSmidth regional product line manager for pumps Diren Lalla.

By incorporating common parts, such as power frames, across various pump sizes, the company ensures that pumps in the KREBS range can be easily upgraded to accommodate new wet-end components. This allows for seamless adaptation to handle higher tonnage when the need arises.

This approach significantly reduces the capital expenditure required for pump upgrades, while simultaneously increasing production tonnages and improving productivity and profitability in the midterm for midtier miners.

Tailored Solutions

To deliver pumps tailored to a specific customer’s needs, FLSmidth collects data on site for analysis to ensure their pump selection is compatible with a particular application.

“It’s not a blanket approach. Each application is handled individually,” emphasises Britz.

Lalla adds that the company also assists with the selection of pumps for greenfield projects, working with engineering companies to design and select pumps for new processes.

“The selection process is facilitated by our pumps programme, which identifies a suitable pump based on all the technical parameters used by engineers.”

For example, in January, FLSmidth tailored a high-speed pump to meet the needs of a gold mining operation in the Democratic Republic of Congo, which required centrifugal sealing.

“This solution promotes sustainability because no water is needed to seal the pump. For safety reasons, we also ensured the selected guards were suitable for the application’s high operating speeds,” highlights Lalla.

Thereby, the company tailored the pumping solution to not only meet the broad duty points but also customer-specific criteria and environmental and safety requirements, he says.

Be Water Wise

The conservation of water is becoming increasingly important, with many mining groups operating in water-scarce environments, emphasising the importance of the sealing arrangements on the KREBS range of pumps.

“While our KREBS pumps can seal pumps in the traditional way using water, as mentioned, we also offer centrifugal sealing, whereby an expeller counteracts the movement of the material trying to exit the pump,” explains Lalla.

FLSmidth has also optimised one of its product ranges to provide “excellent centrifugal sealing”.

Demand for such solutions is high in remote, arid areas where access to clean water is not only a challenge but also expensive.

Using centrifugal sealing, midtier miners can save anything from millilitres to litres a second, depending on the size of the pump, adds Lalla.

“Centrifugal sealing, just like any technology has its limitations, so our pumps can also accommodate mechanical sealing.”

Adopting waterless sealing not only contributes to water savings but also conserves plant footprint because it eliminates the need for water supply infrastructure.

“Midtier miners have 20 to 30 pumps on site, so you’re probably going to need two or three additional pumps just to supply the pumping system with water, increasing the plant footprint,” states Britz.

Optimisation Audits

Increased uptime is critical to a mining operation’s profitability, and to ensure its customers’ plants are always running as efficiently as possible, FLSmidth prioritises plant optimisation by undertaking regular pump system audits.

“This involves auditing our customers’ pumping systems to determine which pump-related challenges they’re facing. Thereby, we can understand the limitations and challenges related to a system and based on this information, determine the best possible solution to extend pump life and improve efficiency and throughput.

“Most of the time, pumps are trialled before they are purchased by a customer to prove that we have confidence in our pump’s ability to meet key performance indicators and deliver better efficiencies and enhanced production capacity,” emphasises Britz.

To ensure that midtier miners are never left in the lurch when a breakdown does occur, FLSmidth’s site visits are also used to collect data on its customers’ parts stockholding and the frequency with which parts are replaced.

“We have digitalised our processes and, using predictive analysis, endeavour to have the right components available at the right time,” says Lalla.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation