Pumps maker targets diamond processing

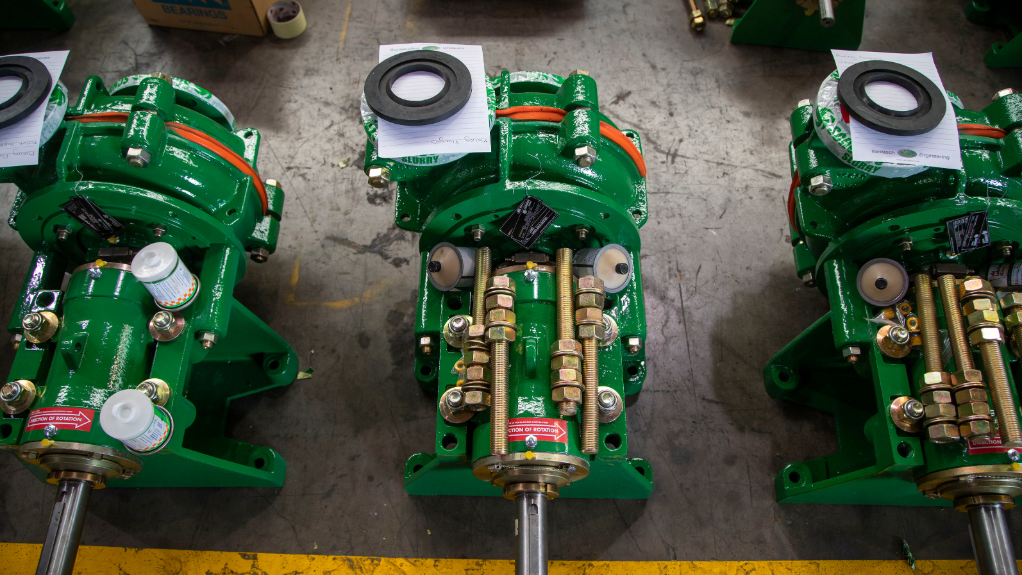

GLOBAL PUMP SUPPLY The company supplies a variety of pumps to diamond processing and beneficiation plants globally

SPECIALISED SOLUTIONS Schurco Slurry’s experience in the diamond mining industry is evident in the company’s specialised pump offerings

DIAMOND INNOVATION The future of diamond mining will depend on how well the industry can adapt to new challenges and opportunities

As the diamond mining industry faces challenges such as resource depletion, increasing operational costs and competition from synthetically made diamonds, heavy-duty centrifugal slurry pump manufacturer Schurco Slurry is expanding its product range to include comprehensive dewatering pump solutions, designed to meet a wide spectrum of applications in the mining sector.

“The future of diamond mining will depend on how well the industry can adapt to new challenges and opportunities,” says Schurco pump applications and project manager Marc Young, noting that Schurco Slurry, in particular, is supporting this adaptation through continuous innovation and by providing high-quality products for customers.

He elaborates that the future of diamond mining in South Africa, and globally, will depend on technological advancements and sustainable practices, and that Schurco Slurry is therefore poised to play a crucial role in the evolving landscape, especially from a pumps perspective.

“Our goal is to be the best friend of diamond processing and beneficiation, just as diamonds are known to be ‘a girl’s best friend’,” says Young.

As such, he states that Schurco Slurry is “committed to delivering the best solutions to customers and supporting the industry’s journey towards a more sustainable and prosperous future”.

In conversation with Mining Weekly, he explains that Schurco Slurry’s experience in the diamond mining industry is evident in the company’s specialised pump offerings.

The company supplies a variety of pumps to diamond processing and beneficiation plants globally, including the S-Series – lined horizontal pumps, U-Series – unlined horizontal pumps, Z-Series – gravel pumps, V-Series – vertical spindle pumps, and D-Series – dual-discharge vertical spindle pumps.

These pumps are engineered to handle the aggressive nature of diamond mining processes, providing reliable and efficient performance across different stages of diamond extraction, explains Young.

“Our pumps are designed with the most rugged materials available. We understand the harsh conditions in diamond mining and have developed solutions that can withstand these environments while ensuring maximum operational efficiency,” he points out.

Young further highlights Schurco Slurry’s commitment to understanding and addressing the specific needs of end-users in the diamond mining sector.

In this regard, the company collaborates closely with process design engineers and mining operators to develop pump ranges and materials customised to the industry's rigorous demands.

This collaborative approach ensures that Schurco Slurry’s products not only meet, but exceed, the performance and reliability expectations of the mining industry, he explains.

“By working directly with end-users, we can design pumps that address their unique challenges,” explains Young, noting that this hands-on approach enables Schurco Slurry to deliver products that are not only reliable, but also perfectly suited to their specific applications.

Schurco Slurry maintains a large inventory of pumps and parts globally, ensuring quick availability and interchangeability with premium slurry pump parts.

This global distribution network is supported by comprehensive refurbishing programmes and bearing assembly exchange or repair options, which serve to reduce downtime and increase operational efficiency for mining operations.

Regional Adaptations

In regions such as South Africa’s Northern Cape province, Lesotho and Botswana, kimberlite ore – typically found in volcanic pipes – requires specialised processing techniques.

Schurco Slurry’s S-, L- and U-Series pumps are commonly used in kimberlite processing plants, which use crushing processes and dense media separation to extract diamonds.

The Z-Series pumps, with their larger passages and reduced internal velocities, are particularly effective in reducing diamond breakage – a critical consideration given that about 30% of diamond breakage occurs within a pump.

“Our Z-Series pumps are designed to reduce particle velocities, which is crucial in minimising diamond breakage,” notes Young. This design feature not only protects the valuable diamonds but also extends the life of the pump.

In contrast, some South African West Coast diamond mining operations, which primarily deal with alluvial gravel deposits, rely on Schurco Slurry’s U- and Z-Series pumps, he highlights. These pumps are designed for ease of maintenance and to reduce the risk of diamond loss during routine operations.

The U-Series pumps feature high-efficiency, non-clog impeller designs and Schurco Slurry expeller seals that ensure zero leakage, making them ideal for the abrasive and corrosive conditions typical of alluvial diamond mining.

“The U-Series pumps are favoured in alluvial plants for their ease-of-maintenance and reliability. They are built to handle the tough conditions and ensure consistent performance,” says Young.

Further, he adds that Schurco Slurry’s technological innovations are central to enhancing the efficiency and productivity of diamond mining operations.

The Z-Series pumps, for example, enable the passage of large particles at low operating speeds, reducing damage to diamonds and extending pump life. This design not only improves operational efficiency but also reduces costs associated with diamond breakage and pump maintenance.

The company’s commitment to research and development ensures that all pump parts are rigorously engineered and performance-tested to meet the absolute highest equipment manufacturing standards, Young adds.

This dedication to quality control and continuous improvement translates into reliable and cost-effective solutions for the diamond mining industry, he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation