Raising the bar in precision large gear and spiral bevel gear manufacturing

This project demonstrates our dedication to excellence for precision, power and performance

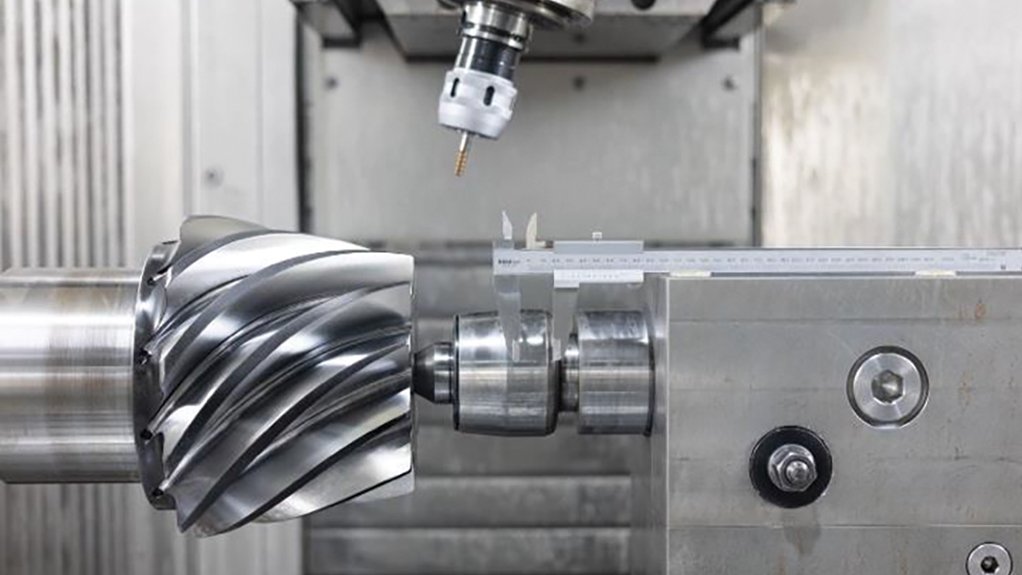

Advanced Spiral Bevel Gear Manufacturing

In the demanding world of mining, reliability is not optional — it is engineered. One of South Africa’s leading manufacturers of large industrial gears, Ultragear continues to invest in advanced machining and grinding technology to deliver world-class gear solutions with shorter lead times and uncompromising quality.

With the commissioning of the Klingelnberg Rapid 3000 gear grinding machine, Ultragear significantly expands its capability in large-gear precision finishing. Together with advanced spiral bevel gear manufacturing, these investments position Ultragear as a key partner to the mining, power generation and heavy industrial sectors across Southern Africa.

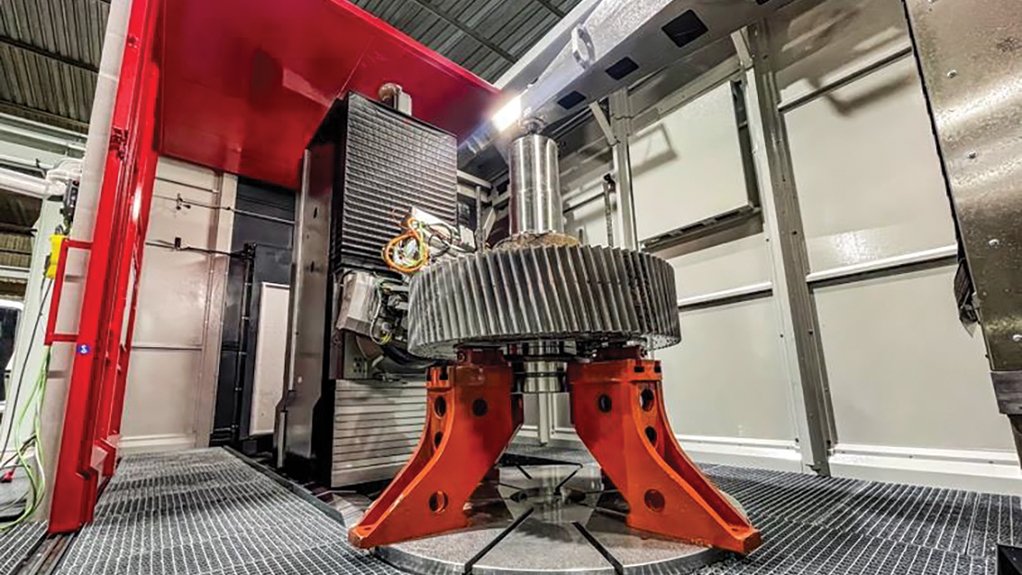

The Klingelnberg Rapid 3000 represents a significant advancement in Ultragear’s external gear grinding capability. Designed specifically for large gears (3 000 mm diameter / 5 000 mm length shafts), the machine enables the finishing of gears to exact tolerances, improving load distribution, noise behaviour, and overall service life. For mining operations, precision external gear grinding is critical in applications such as mill drive gearboxes, open and enclosed girth gear systems, crusher drive gearboxes, and high-torque conveyor gearboxes. By integrating advanced measurement and correction processes, the Rapid 3000 also allows Ultragear to achieve consistent, repeatable results — an essential requirement for large gears operating in high-power, high-consequence environments.

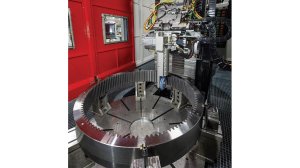

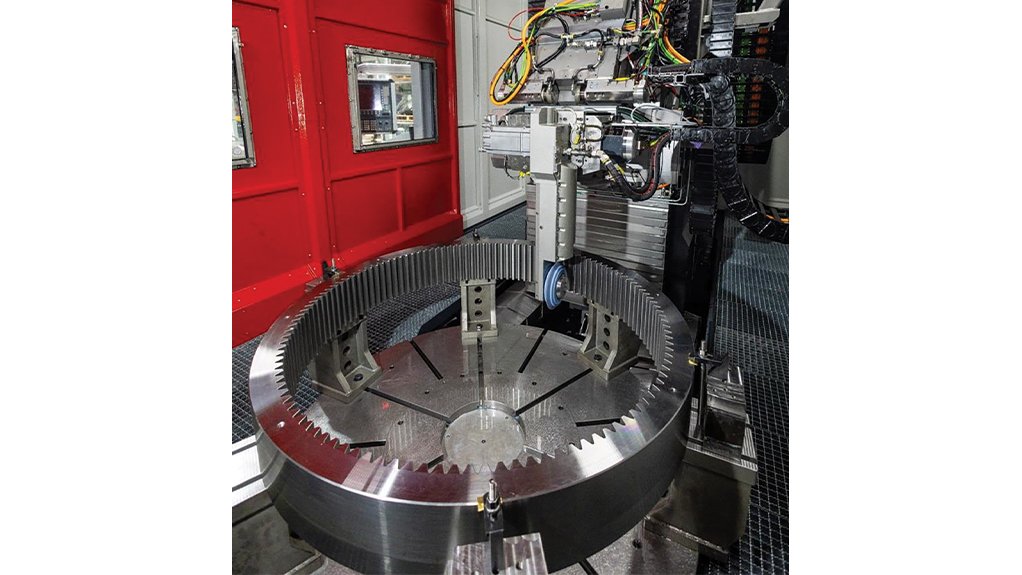

A defining capability of the Klingelnberg Rapid 3000 at Ultragear is the ability to precision-grind internal gears up to 3 000 mm in diameter. This capability is particularly valuable for planetary propel gearboxes, mill gearboxes, large slew and swing drives, and bucket wheel excavator drives, where internal ring gears play a critical role in torque transmission and load sharing. Precision grinding of these internal gears improves meshing accuracy, reduces vibration, and contributes to higher gearbox efficiency, reliability and service life. By offering this capability locally, Ultragear eliminates the need for importing, reducing lead times, logistical risk and downtime — a decisive advantage for any industry operating on tight shutdown schedules. Historically, large internal gear grinding was a rare and costly process, often placing it beyond practical reach. With this capability now available locally, Ultragear can apply precision grinding to internal ring gears that were previously left unground, enabling performance improvements to existing gearbox designs through better tooth contact and load sharing.

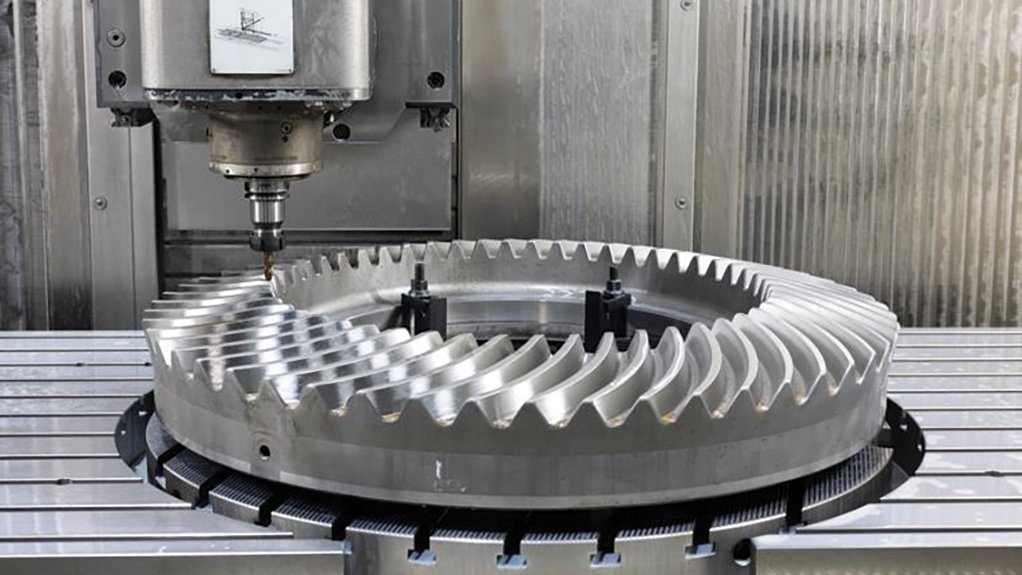

Spiral bevel gears are essential wherever high power must be transmitted through a change in direction. Ultragear manufactures these complex components entirely in-house using DMG DMF 260-11 and DMG DMU 75 - 5-axis machining centres, ensuring precise control over gear geometry and quality. Ultragear can manufacture spiral bevel gears 2 000 mm in diameter, with pinions 3 000 mm in length, supporting demanding applications such as crusher main drive gearboxes, mill gearboxes, conveyor drives, and stacker-reclaimer drives.

Manufacturing spiral bevel gears locally in South Africa provides a clear advantage in speed and responsiveness. Customers benefit from reduced lead times, close engineering collaboration, and the flexibility to respond quickly to design changes or urgent replacement requirements.

Our gear and gearbox solutions are used across mines, power stations, steel plants, sugar mills, cement works and paper factories.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation