Regaining control of boiler and burner operations with Combustion Technology

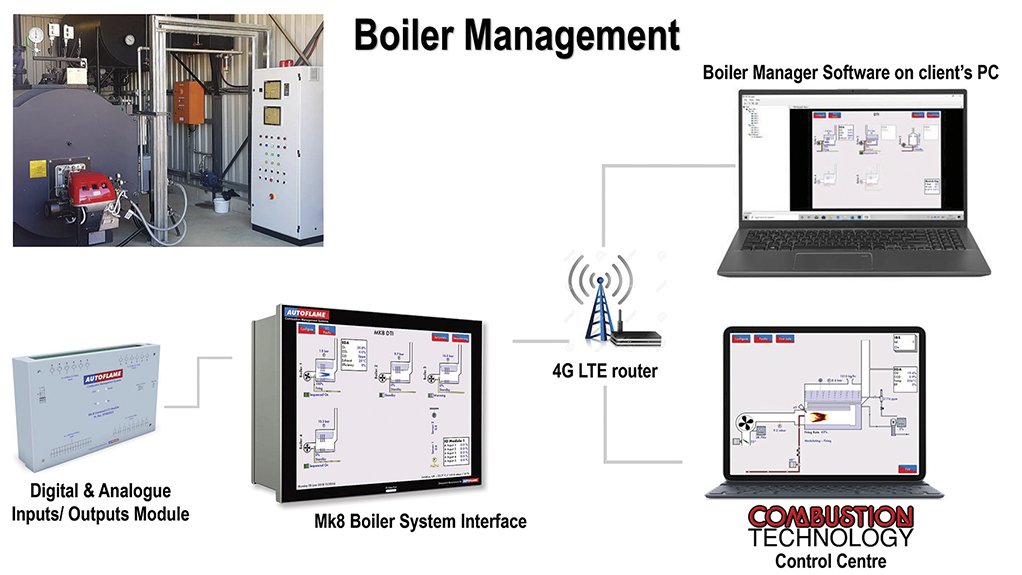

Combustion Technology’s Boiler System Interface solution helps restore control of equipment and facilities, enabling full management of all boiler house key functions.

Through its 12.1” user-friendly multitouch screen interface, Combustion Technology are able to log on to any equipped site and view all operational boilers and burners in real time.

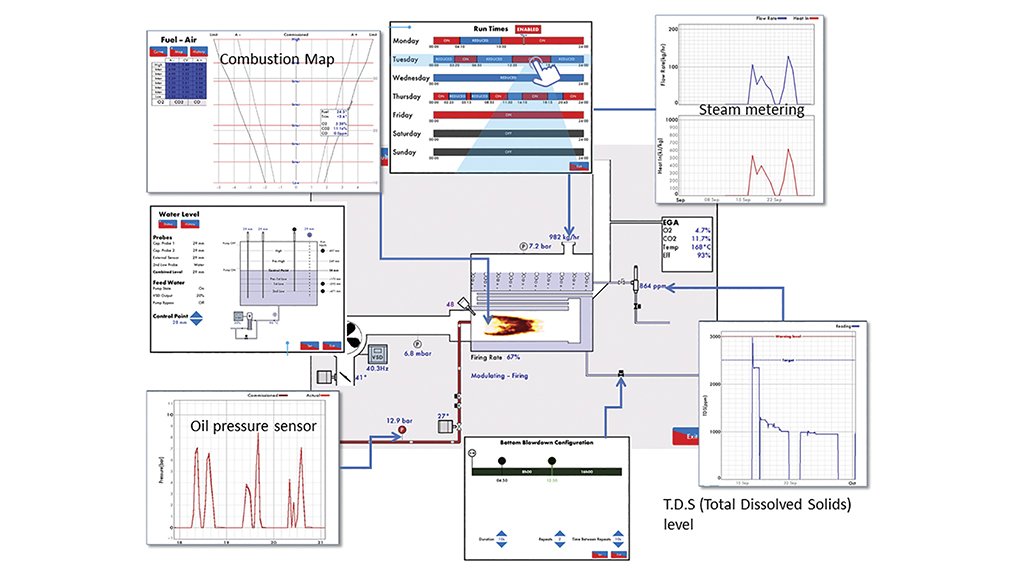

Using Combustion Technology’s Exhaust Gas Analyser to sample exhaust gases, readings are fed back to the controller. Good emissions indicate good combustion, which translates to reduced fuel consumption, reduced carbon taxes and overall cost savings.

The Boiler System Interface solution allows for up to 10 boilers to be connected on a single site and enables round-the-clock management of a range of functionalities, including:

- All burner functions

- Steam flow metering

- Water level control

- Fuel consumption compared to steam generation

- Fuel pressure

- Ideal emissions (O2, CO2, CO)

How it works

- The Boiler System Interface collects and stores critical data history for up to two years

- Combustion Technology connects to the Boiler System Interface by means of a router built into its control panel

- The central control room monitors all key parameters on a connected plant, 24/7

- Alarms alert Combustion Technology engineers if set points drift off commissioned values

- Interventions are actioned immediately to ensure that the highest efficiencies are maintained at all clients’ boiler plants

The Mk8 Universal Input Output (IO) module logs analogue inputs and outputs when connected through the Boiler System Interface. Digital and analogue inputs and outputs are contained in one unit and can be used for a number of applications.

Analogue signals include:

- Feedwater temperature

- Oil pump pressure

- Steam pressure

- Fuel flow rates

- Feedwater flowrates

Digital signals include:

- Burner status

- Pump status

- Fan status

- Valve status

Benefits of Combustion Technology’s Boiler System Interface solution

- Diagnostics of maintenance and performance issues that could affect boiler downtime or shut-down for unplanned maintenance

- Fuel and water flowmeters monitor actual fuel usage and trend fuel to steam ratios

- Monitoring of emissions that directly relate to fuel consumption

- Emissions management to ensure compliance with national environmental requirements for boiler fuel gas emissions

- 24/7 expert advice from a service provider with a best-practice service level agreement

- Monthly performance reports include data of a system’s overall performance and steam production, as well as recommendations to optimise performance

- Site’s full data history stored for 2 years

- Burner/boiler alarms, lock-out settings and ‘first-outs’ are monitored and timeous email notifications are sent

Combustion Technology provides modern, world-class and highly efficient environment-friendly solutions to meet any combustion and heating challenge.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation