Gear units prove successful in mining industry

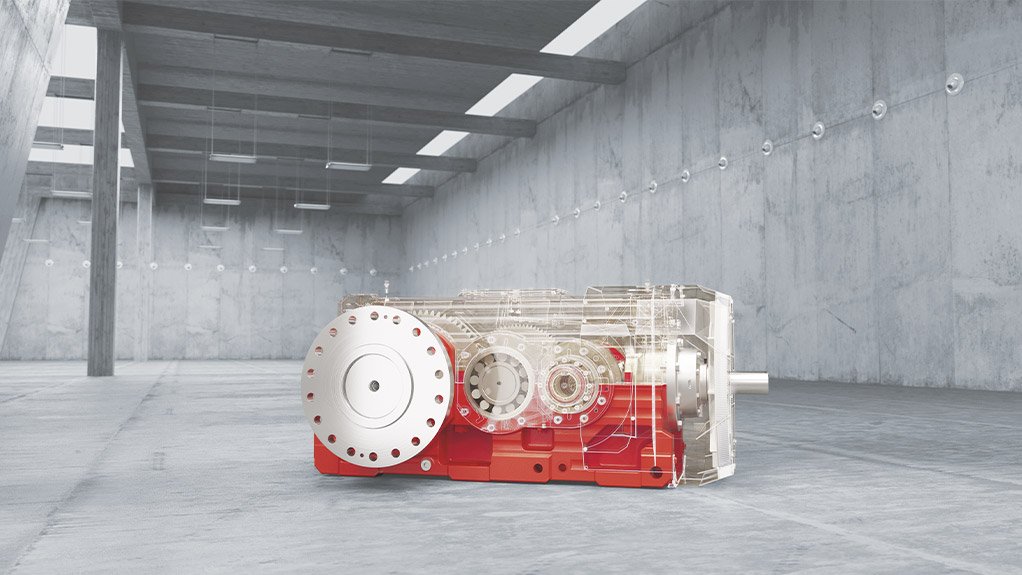

TOP GEAR The revamped gear units have been welcomed into the industry with open arms

Since launching the X.e Series, an upgraded version of its X Series industrial gear drive unit, drive component manufacturer SEW-Eurodrive says the X.e Series has been well-accepted by the local mining industry.

The revamped industrial gear units in the X.e Series offer between 15% and 20% improvement on emitted thermals, which allows for substantial energy savings, depending on the application and industry in which the unit is used.

“The X.e Series is even more suited to the harsh mining and industrial environments than any of our preceding gearboxes,” notes SEW-Eurodrive MD Raymond Obermeyer, suggesting that the gearbox must be robust in terms of its internal components and external body structure.

The upgrades – developed at the Ernst-Blickle-Innovation-Center (EBIC) in Bruchsal, Germany, which serves as the worldwide centre of all research and development activities of SEW-Eurodrive – were announced in April at the Hannover Messe Fair, also in Germany.

The upgrades involved decreasing the ambient thermal loss by improving oil levels, and optimally improving oil bath temperatures. Subsequently, increased operational safety, saving on resources and longer intervals between oil changes have also been noted. The greatest benefit is the increased thermal rating of up to 32%.

“Decreasing the thermals on a gearbox unit is one of the best ways of increasing efficiency,” notes Obermeyer. He adds that SEW-Eurodrive has also undertaken to optimise the X.e Series using more appropriate bearing selection, a revised sealing system, improved pinion housing and optimised gearing topology.

Obermeyer says the selection of a more appropriate bearing allows for effective load bearing, which increases the service life of the gear unit by up to 220%.

Meanwhile, the revised contactless sealing system negates wear on the input and output shaft, decreasing oil loss significantly. Further, the basis for the higher thermal rating is achieved through the improved bevel pinion housing, which improves the unit’s oil flow. This, in turn, allows for higher power transmission without the risk of unexpected downtime, while higher operational safety is also achieved.

“Optimised gearing topology allows for a better tolerance to meshing interference, increasing system availability,” notes Obermeyer.

He suggests that the upgraded gear units can tolerate ambient temperatures from as low as –40 ºC to desert conditions, and underground temperatures that could reach 50 ºC.

“In the desert, there are not only extreme temperatures but also fine sand that can affect the running of the gearbox. The new X.e Series is better equipped to manage these challenges,” asserts Obermeyer.

The X.e Series can be applied to various industries, and is available in different configurations to meet client requirements. SEW-Eurodrive offers the gear units with a torque ranging from 65 kN to 500 kN.

The X.e Series is being assembled locally by SEW-Eurodrive’s qualified technicians, who were trained at EBIC after the global launch. “SEW-Eurodrive’s assembly facility in Nelspruit, Mpumalanga, has received stock of the necessary components, with units being sold and used in the mining sector.”

SEW-Eurodrive South Africa assembles and distributes gear units to South Africa, as well as 23 other countries in and around Africa. The company has also exported to other regions such as Canada, Russia and Australasia.

“We are very proud to say that, so far, the new X.e Series has been well received and we look forward to a good challenge with our longer-standing gear unit competitors,” quips Obermeyer.

“The main goal is to offer a better product with better efficiencies, bearing life and thermals – this is what led to the whole revamp,” concludes Obermeyer.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation