Sandvik builds its base to grow lifecycle screening solutions across Africa

Tarynn Yatras, Vice President of Sales Area Africa for Sandvik Rock Processing Solutions

Sandvik Rock Processing is focused on a lifecycle approach with customers

As a global player in the screening space, customised solutions are a clear focus for Sandvik Rock Processing

The Sandvik Rock Processing facility in South Africa is the first one globally capable of producing all the company’s screening product lines

This article has been supplied.

To provide customers with screening solutions that suit their needs and fit their infrastructure, OEMs must be close at hand with the right facilities and expertise, according to Mats Dahlberg, Sandvik's Vice President for Screening Solutions in Europe, Middle East and Africa.

This is a key element of the strategy being rolled out in Africa by Sandvik Rock Processing, as it takes a leading position in bringing customers innovative solutions for the full lifecycle of screening equipment. The extensive footprint of the Sandvik group on the continent is being leveraged, with entities being empowered with training and extra resources to support its full range of screens.

“Our screening offering now includes a wide range of capacities and applications, which we can support through our strong presence in Africa,” says Dahlberg. “A strategic priority is being close enough to customers to understand their requirements in detail, and customise solutions to align with existing site infrastructure.”

“This requires a strong local presence and technical competencies, along with a regional supply chain for better responsiveness,” he says. “This can be achieved alongside the global commonality of screen components, which ensures customers of a safe, reliable and tested product.”

Sandvik already has registered entities in Zimbabwe, Botswana, Namibia, Democratic Republic of Congo, Tanzania, Zambia, Ghana, Mali and Burkina Faso, and a distributor in Mozambique. Tarynn Yatras, Vice President of Sales Area Africa for Sandvik Rock Processing Solutions, highlights that the company has already begun employing more resources to strengthen the technical capability of these entities in the field of screening.

“We are also able to hold higher volumes of spares and components in-country, for instance, reducing lead times for customers,” says Yatras. “Customers of all our screen ranges and brands have started to see the benefit of our enhanced in-country support.”

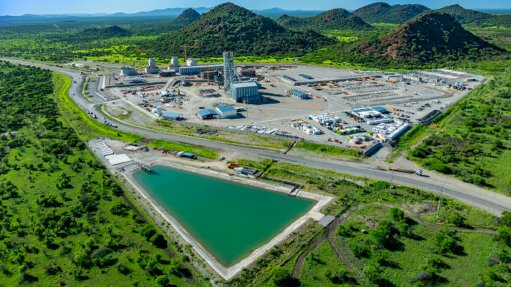

SAM by Sandvik is expected to play a more important role as a digital platform through which customers can receive remote support and other digital services. Local manufacture of screens has also been an important feature of the company’s expansion strategy in Africa. The Sandvik Rock Processing facility in South Africa is the first one globally within Sandvik to be capable of producing all the company’s screen product lines. It has also begun producing original Sandvik screens and feeders for local customers.

As a leading global screening solutions media supplier, the strategic focus in Africa will also include strengthening the existing local manufacturing capability and supply chain for screening media.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation