Sandvik launches Leopard DI650i drill rig

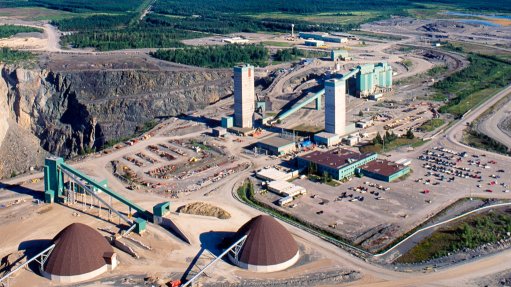

Sandvik Mining and Rock Technology’s Leopard DI650i drill rig

Photo by Nadine James

Sandvik Mining and Rock Technology has expanded its high-pressure down-the-hole (DTH) drill rig offering, with the introduction of the new Sandvik Leopard DI650i model.

The drill was unveiled to the market for the first time at Electra Mining Africa, being held this week at the Nasrec Expo Centre, in Johannesburg.

The drill rig is designed for 115 mm to 203 mm size holes, for high-capacity production drilling applications in surface mining, and for large-scale quarry applications.

Unique features of the drill include automation, which is scalable for future advancements; and an iCab cabin, designed for operator safety and comfort.

The cabin also facilitates training, with space for more than one person at a time.

Sandvik surface drilling and exploration president Joanne Cooke says the drill rig is “very easy to service”, with both sides accessible from ground level for daily maintenance.

The drill rig is fuel-efficient owing to intelligent control technology in the compressor and hydraulic system’s cooler fan, presenting an economic, productive and cost-effective option for Sandvik’s customers, she posits.

This rig is the culmination of three years’ worth of design, testing and manufacture by Sandvik.

Notably, Sandvik collaborated with Aveng Moolmans in designing this rig. Cook indicates that Sandvik took into account input from Aveng Moolmans’ team in South Africa, gleaned from operator feedback and requirements.

Aveng Moolmans MD Stuart White says the company is in the process of finalising the deal for the rig with Sandvik, which is set to be used at one of the company's operations in the Northern Cape.

This location was chosen for logistical purposes, as Sandvik will be on hand to mitigate any challenges that may arise from first-time onsite operation.

“We are very excited about this rig, owing to the intelligent features and the accurate drilling and fuel savings it enables,” White concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation