Sandvik Rock Processing introduces remote monitoring service in Africa

Nils-Peter Ahlqvist, Sales Support Manager Africa & Latin America – Crushing Division at Sandvik Rock Processing

Sandvik Rock Processing is piloting its Remote Monitoring Service (RMS) in Africa

RMS translates vast amounts of data acquired from Sandvik crushers into actionable recommendations

RMS utilises a data-driven study of abnormal behaviour in terms of both crusher performance and health to generate tangible remedial action informed by data

The machine visibility RMS provides allows for the replacement of wearing parts before they wear out

With RMS, mines and quarries can expect increased efficiency within their operations

This article has been supplied.

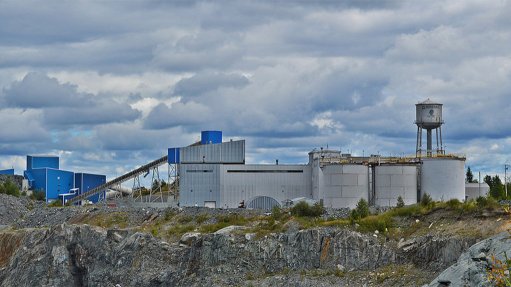

At a time when quarries and mines seek to optimise their operations and ensure continuous improvement, remote monitoring of crushing data is becoming a crucial element of day-to-day procedures. To meet this growing need, Sandvik Rock Processing is piloting its Remote Monitoring Service (RMS) in Africa.

Crushing operations in Africa can look forward to a new set of digital services following Sandvik Rock Processing’s announcement at Electra Mining Africa 2024 that it is piloting its RMS – a digital system that allows for monitoring of crushing processes remotely.

“RMS is the latest addition to our suite of existing digital technologies. It complements our ever evolving Automation and Connectivity System (ACS) and SAM by Sandvik cloud-based digital assistant,” explains Nils-Peter Ahlqvist, Sales Support Manager Africa & Latin America – Crushing Division at Sandvik Rock Processing. “RMS translates vast amounts of data acquired from Sandvik crushers into actionable recommendations, reducing operating costs and boosting productivity and sustainability.”

RMS utilises a data-driven study of abnormal behaviour in terms of both crusher performance and health to generate tangible remedial action informed by data. In essence, it provides real-time data that allows customers to anticipate problems before they occur, thus avoiding surprises.

In addition, the machine visibility RMS provides allows for the replacement of wearing parts before they wear out. Collected data over a period of time will provides insights into parts that are replaced frequently, allowing customers to keep these in stock at all times and avoid unnecessary downtime.

With RMS, mines and quarries can expect increased efficiency within their operations. Continuous analysis of real-time data round-the-clock helps operations get the most out of their equipment, minimising downtime and maximising uptime. Higher uptime translates into higher machine utilisation which, in turn, reduces cost-per-hour.

“In addition, the data gathered on crusher performance makes optimisation easier with the ultimate goal of enhancing business performance. The alerts, available 24/7, also help reduce high wearing of crusher components, which is detrimental to material consistency and has negative cost implications,” says Ahlqvist.

Keeping machines running in optimal condition translates into reduced energy consumption which not only results in cost effective operations, but also allows customers to reduce their environmental impact.

“Energy efficiency and sustainability have over the years become a key part of business decisions for mining companies, especially on the back of growing pressure for the industry to improve its sustainability performance. With RMS, we are bringing yet another set of advanced digital services to help the industry increase efficiency while reducing carbon emissions,” concludes Ahlqvist.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation