Sandvik Rock Processing Screening Solutions builds on Africa footprint for screen business

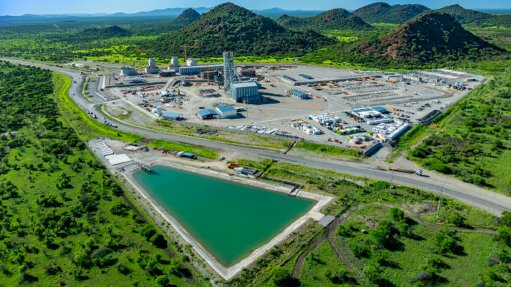

Having an in-country presence allows Sandvik Rock Processing to service customers across Africa

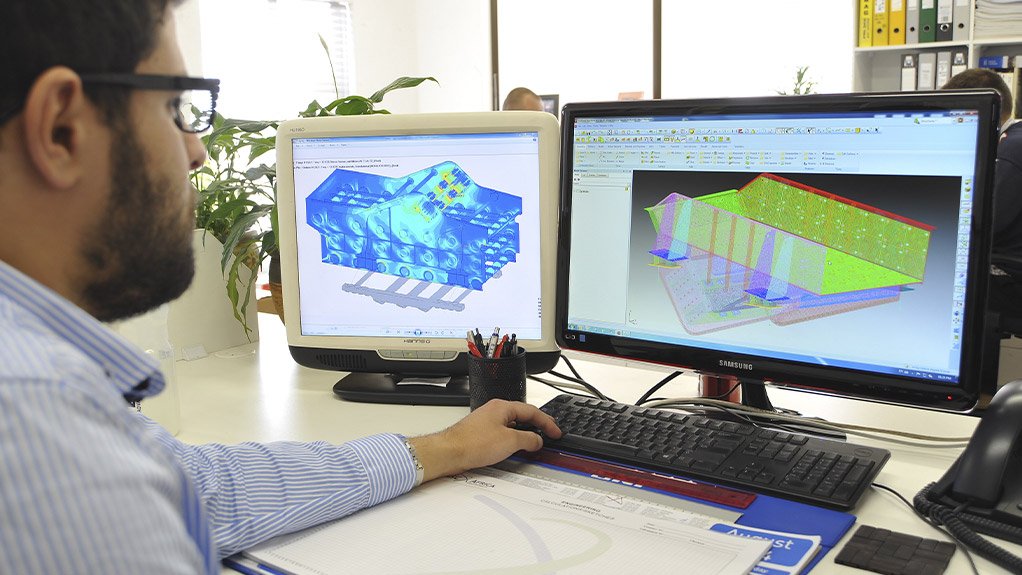

Sandvik Rock Processing has skilled individuals in its design team at its South Africa facility.

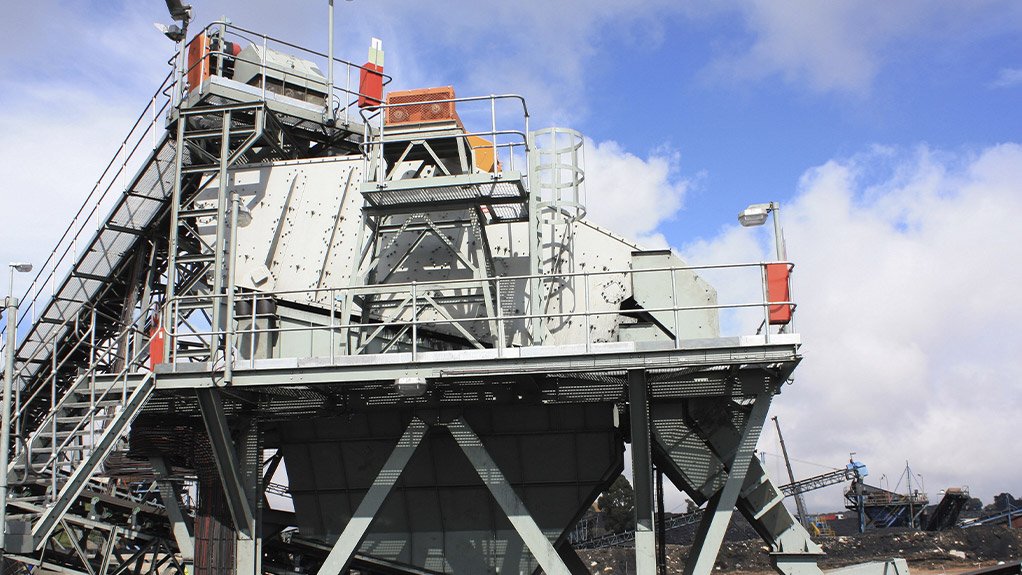

A double deck vibrating screen in a coal application

This article has been supplied.

It is a well proven fact that companies succeed where they are closest to their customers, and this is driving Sandvik Rock Processing to leverage the extensive Sandvik footprint across Africa.

According to Gavin McLaggan, Lifecycle Services Manager at Sandvik Rock Processing Screening Solutions, customers in the crushing and screening markets can now have quicker access to support within the region or country. This allows the same high standard of support for all its products, including the Sandvik, Kwatani and Schenck screening products – which are all now supported by Sandvik Rock Processing.

“We recognise the importance of being close to our customers and aim to establish long term relationships with them,” says McLaggan. “Having facilities that are close to our customers throughout Africa is crucial for our support-driven strategy, and we believe this differentiates us significantly from competitors.”

For instance, he explains there are regional Sandvik offices in South Africa for the Southern African area, in Zambia for Central Africa and in Ghana for West Africa – as well as country offices in nine other countries. The presence of existing workshop facilities and spares warehousing is a real gamechanger for growing Sandvik Rock Processing’s screening business.

“As Sandvik rock Processing, we are prioritising the presence of our teams on the ground in countries where our screening equipment is already working,” he says. “By leveraging Sandvik’s strong presence in most countries, we can react rapidly and provide backup support whenever and wherever it is needed.”

Many customers will have the benefit of in-country refurbishment opportunities, for instance, instead of having to send equipment cross-border for mechanical attention. The local support means lower transport costs, faster turnaround times and less operational downtime. This includes the availability of technicians and specialists to give customers optimal assistance throughout the lifecycle of their screens.

“Closer proximity to customers also allows them to have their equipment serviced more regularly – and to OEM standards,” he explains. “By focusing on the entire lifecycle and reducing the total cost of ownership, Sandvik Rock Processing aims to provide customers with enhanced value and improved outcomes.”

He highlights that the high quality of workmanship gives a second life to these machines, further improving their contribution to mining customers’ bottom line profitability. The local footprint also gives Sandvik Rock Processing easier access to customers’ sites, so they can become more familiar with their specific challenges and requirements.

“Mines are increasingly looking to their supply partners to hold as many of their consumable items and critical spares as possible,” says McLaggan. “As we leverage the Sandvik footprint, Sandvik Rock Processing is engaging with customers to ensure we understand their current and future needs, so we can develop our spares holding capacity of in-country offices accordingly.”

This capacity building strategy also includes the technical training of personnel in various countries, equipping them to deliver maintenance, repairs and refurbishment in line with ISO quality standards. Developing long term relationships with customers is a key aspect of the Sandvik vision, he emphasises.

“We are continuing to build the business so that customers are assured that we will always be here with the support they need,” he concludes. “This is what maintains and develops the positive trust on which strong relationships are based.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation