Santa Comba tungsten/tin project, Spain

Name of the Project

Santa Comba tungsten/tin project.

Location

The municipalities of Santa Comba, Coristanco and Cabana de Bergantiños in the province A Coruña, in north-western Spain.

Project Owner/s

Rafaella Resources.

Project Description

A prefeasibility study (PFS) completed on the project in June 2022 has shown the project to be economically robust, complementing the permitted underground mine and offering significant upside, owing to its scalability.

The project has proven and probable ore reserves estimated at 7.48-million tonnes at a grade of 0.15% tungsten oxide (cutoff of 0.05%) for 12 374 t of contained tungsten oxide.

The mine plan combines the exploitation of two pits – Main pit and Eliseo pit.

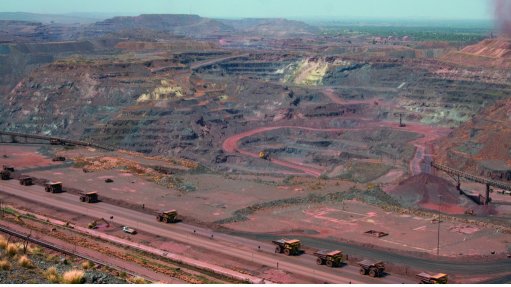

Lower-grade, endogranite-hosted mineralisation will be exploited through an openpit over seven years. Conventional openpit mining will be practised. This will entail drill-and-blast and haul-and-dump mining methods using hydraulic excavators and trucks. The openpit operation is expected to deliver 7.4-million tonnes of tungsten over the life-of-mine.

The project includes the construction of a 1.3-million-tonne-a-year processing plant comprising the crushing of run-of-mine ore, X-ray ore sorting, grinding, a gravity concentrator consisting of centrifugal concentrators, shaking tables and a magnetic separator.

Tungsten concentrate will be floated to eliminate sulphides and leached to remove any remaining deleterious elements, producing a clean calcium tungstate – a premium tungsten product that is sought-after by end-users.

A one-million-tonne-a-year aggregates plant, located close to the waste storage facility, will monetise the mine waste by producing granite aggregates.

The permitted underground mine does not form part of the openpit advanced PFS.

The openpit is complementary to the recommissioning of the high-grade underground operation, containing Joint Ore Reserve Committee-compliant resources of 2 752 t of contained tungsten oxide and 662 t of contained tin, with an additional exploration target of between 6 000 t to 12 400 t of contained tungsten oxide and 1 300 t to 2 200 t of contained zinc.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The openpit-only scenario has an estimated pretax net present value, at a 4.5% discount rate, of $67.3-million and an internal rate of return of 32.6%, with a payback of 2.3 years after commissioning.

Capital Expenditure

$37.78-million.

Planned Start/End Date

Not stated.

Latest Developments

The PFS results support Rafaella’s application for strategic industrial project status to accelerate the permitting process.

Key Contracts, Suppliers and Consultants

Tomra Sorting and Grinding Solutions (metallurgical testwork – mineral processing plant).

Contact Details for Project Information

Rafaella Resources, email info@rafaellaresources.com.au

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

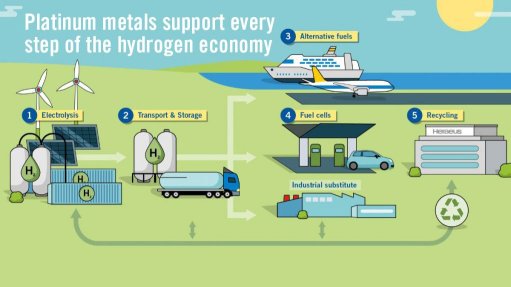

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation