Repair service underpins company’s support of industrial sectors

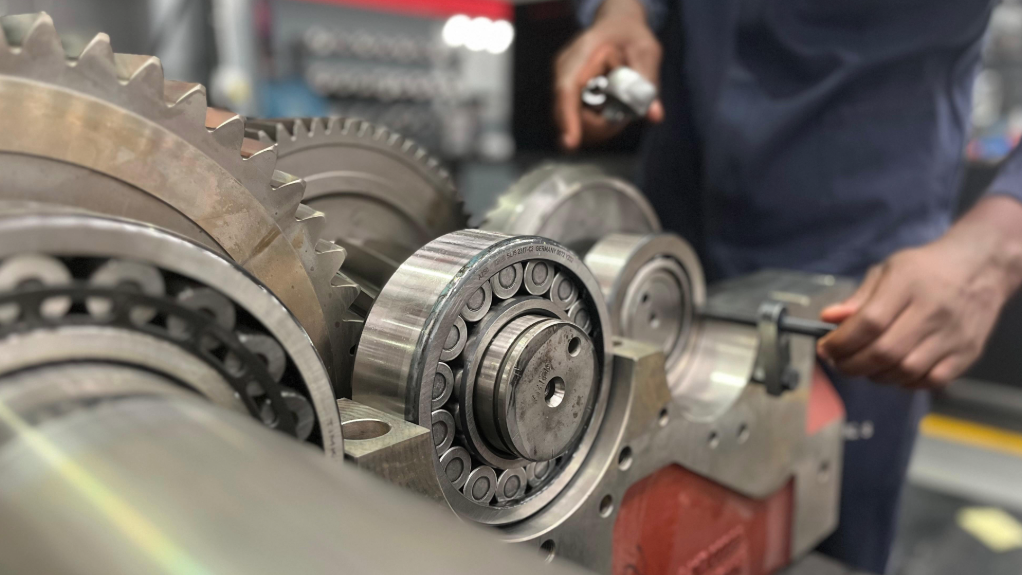

HANSEN IGU MANUFACTURE BMG is the OEM for the range of Hansen IGUs for various industrial operations and applications

RELIABLE GEARBOXES The Hansen IGUs and gearboxes are designed and built for reliability and efficiency

Industrial equipment supplier BMG repairs Hansen industrial gear units (IGUs) in strict accordance with the manufacturer’s documented procedures, thereby preserving the design tolerances and operational reliability required for demanding industrial environments. This forms part of BMG’s ongoing commitment to key industrial sectors, including water and wastewater treatment, mining and petrochemicals.

Hansen IGUs enhance motor and drive system operationality – beyond gearbox optimisation – by delivering “exceptional reliability” and reducing downtime through precision-engineered load distribution and robust bearings that effectively handle axial and/or radial forces, says BMG electromechanical division and gears regional manager Barry Stoltz.

Hansen IGUs have advanced sealing systems to ensure leak-free operation, thereby minimising maintenance requirements. Their modular designs facilitate quick high-speed stage replacements, while their tapered roller bearings with increased spans provide “superior overhung load capacity”, allowing for smoother, quieter runs. This reduces energy loss, extends life span and facilitates higher system precision for motors.

Stoltz notes that well repaired Hansen IGUs are crucial for operational reliability because original equipment manufacturer-standard repairs using genuine components restore them to original factory specifications, preventing premature failures. This, in turn, minimises unplanned downtime, reducing costs, and helps to ensure continuous production in demanding sectors.

“Proper repairs address wear in bearings, seals and gears, boosting uptime, performance and longevity while reducing maintenance costs, compared with full replacements. In high-stakes applications, this compliance with authorised procedures enhances safety, regulatory adherence and overall system efficiency.”

Repair of every Hansen gearbox is completed by BMG’s “highly-skilled service teams” to ensure that every gear, bearing, shaft and housing meet the original specifications for fit, alignment and performance.

Stoltz adds that BMG provides the highest level of care required for the complex design of the IGUs to ensure optimum performance in the demanding environments in which they typically operate.

“Our objective is to return every Hansen gearbox to its original operating specification, thus ensuring long-term reliability and protection of each customer’s capital investment. It is crucial that this service is undertaken only by Hansen-approved specialists, as this is critical to maintaining the gearbox’s design integrity, operational reliability and life span.”

The repair process starts with incoming inspection and full disassembly, followed by the cleaning and preservation of all parts. Bore tolerances in housings, shafts and gears are measured to confirm dimensional accuracy. Maintaining these tolerances prevents excessive wear, vibration and heat generation, extending gearbox service life.

The company ensures that it maintains Industry Organisation for Standardisation (ISO) standards, including ISO 286-1 and ISO 286-2.

“All bearings and seals are replaced, and reassembly is completed by BMG specialists with precise control of bearing clearances and gear contact patterns. Fasteners are torqued to specified values and contact patterns are checked to confirm correct gear mesh. A no-load test verifies temperature, lubrication, noise and oil tightness, before final paint finishing in the distinct Hansen RAL 5019 capri blue.”

The company also offers products, such as Sumitomo and NORD drive systems, which reliably enhance productivity and sustainability.

Stoltz highlights that the company has various complementary solutions for harsh environments that will ensure IP66 protection, Class H insulation, reduced noise and extended service life, including the “high- efficiency” Synergy IE3, IE4 and IE5 electric motors.

These motors – complemented by modular NORD Drive Systems for precise mechanical speed control and Synergy PI150 frequency inverters for energy efficient operations – support applications in water treatment, chemicals and cement, among others.

Additionally, BMG has a long-standing partnership – spanning more than 13 years – with engineering and machining solutions company Danfoss.

The partnership enables BMG to supply solutions, such as VLT, iCX and VACON variable-speed drives, as well as soft starters, that reduce harmonics and energy use by up to 80%. This is relevant in soft starter condition monitoring of automation in mining, processing, and heating, ventilation and air conditioning applications.

BMG has also been an authorised Danfoss DrivePro service partner since 2019, further emphasising its commitment to supporting clients by ensuring minimal downtime through its extensive branch network and technical expertise.

The company also provides efficient after-sales support through field services and condition monitoring teams.

“BMG operates approved workshops in the Western Cape, Gauteng and KwaZulu- Natal for repairs, commissioning, upgrades and panel manufacturing, [with] 24/7 support, short lead times and specialised training,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation