SEW-EURODRIVE drives Africa’s mining sector with strengthened regional capability

Reverse engineering for industrial gear units of all manufacturers

Drive Radar

Service and Repair Centre

Growing investment in mineral processing capacity across Africa has accelerated demand for reliable drive technology, creating strong momentum for drive technology company SEW-EURODRIVE’s operations throughout the region. Over the past year, the company has secured major contracts across key commodities, reflecting its expanding role as a critical partner to mining operations in 23 African countries.

SEW-EURODRIVE’s success is built on almost three decades of engineering experience and close collaboration with original equipment manufacturers; engineering, procurement and construction management contractors; and mining companies. Its involvement from early project stages ensures that drive systems are accurately specified, correctly sized and aligned with long-term mine plans. The company continues to broaden its offering with an expanded planetary gearbox portfolio and growing capability in open gearing girth gear solutions for mills, crushers, agitators and conveyors.

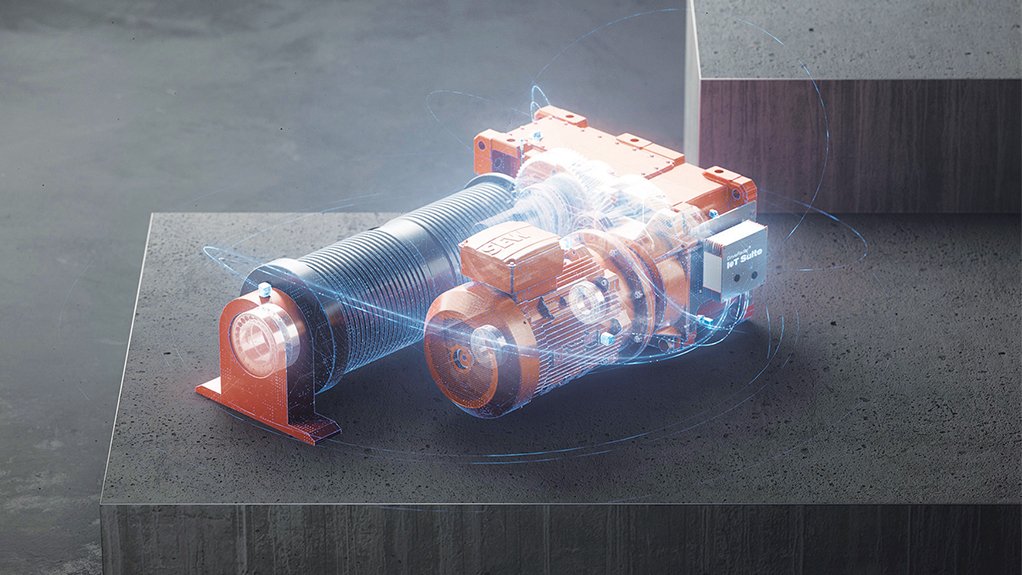

Energy performance and equipment reliability remain central requirements for mining customers. SEW-EURODRIVE supports these priorities through ongoing technology development, on-site energy surveys and real-time condition monitoring using its DriveRadar® predictive maintenance suite. This system tracks key indicators such as vibration, oil condition and temperature to help mines prevent unplanned downtime.

Skills development is reinforced through the SEW-EURODRIVE Drive Academy, which delivers structured training for artisans, engineers and plant personnel and supports internal technical development.

A substantial investment in local manufacturing and service infra-structure strengthens the company’s responsiveness. Stock-holding now exceeds R500-million, backed by the expanded Aeroton facility with motor repair and rewinding capability, CNC machining, balancing, 3D scanning and upgraded assembly and service lines. This integrated capacity allows SEW-EURODRIVE to deliver faster turnaround times and improved lifecycle support across the continent.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation