Simplifying dewatering through Innovation

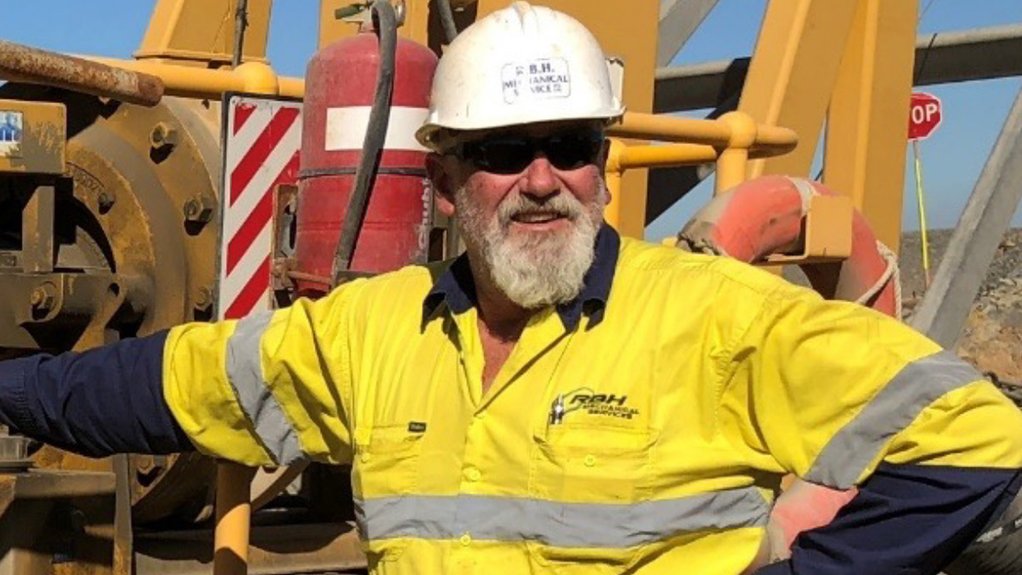

Having worked with screens that clog and cause pump damage to capital intensive dewatering solutions like pontoon, barge, gantry track and deepening the RDAs or TSFs, Turret Engineering MD Rob Hair gained valuable insight and expertise to propose a solution to overcome these challenges. The journey of innovation and delivering a global solution is a significant commitment that impacted the inventor personally, financially and professionally.

As an innovative business leader, Hair is committed to the health and wellbeing of people, a sustainable environment and undertaking to deliver these goals sustainably and safely.

As a result, Hair rehashed, developed and tested 15 prototypes until finally arriving at the solution.

Conceptual Thinking & Determination

Hair engaged a panel of consultants who are leaders in the field of hydrology, technology, tailings, water management and mining. The innovative solution he came up with is fully backed by engineering concepts, flow modelling, a rigorous testing regime and followed a process of commercialisation, which included worldwide patenting.

Dr Jeremy Leggoe, a senior lecturer in the School of Engineering at the University of Western Australia, undertook the modelling and declared that the Turret™ design offers reduced friction losses compared to most conventional intake configurations, even with screens fitted.

After many years of tireless pursuit and commitment to deliver reliability, quality and innovation, Hair succeeded in launching the solution “Turret™” into the global arena. Turret™ is now globally accepted as the solution for dewatering in shallow waters.

Challenging and Jubilant Moments

“When we developed and launched the first commercial unit, we were offering free trials and an opportunity to demonstrate the superior design capability that helps overcome cavitation, vortexing and performance issues.

“It took a few years before clients, engineers and the market started to recognise Turret™ as the true leader in innovation, with value that outperforms any conventional methods. Now there are many miners, engineers and pump companies who trust Turret™ to deliver the value proposition in shallow water dewatering,” explains Hair.

Scalable Solution

Once the company gained some traction from the mining industry, the general interest from various segments was astonishing. While the Turret (3m) Mega-Flow is preferred for large scale mining operations, there was great interest for Turret™ from emergency services for firefighting, water corporation, sewer treatment, construction and farming, among others, he notes.

Hence, the company’s innovation expanded into providing pragmatic solutions through the following products:

- Turret™ (3m Mega-Flow) and Turret™ (1m Mini-Flow), with the Turret™ (3m Mega-Flow) handling 1 000 m3/h and the Turret™ (1m Mini-Flow) handling around 100 m3/h with low friction loss.

- Turret™ retrofitted with submersible pumps offers a plug and play solution.

- Turret™ design can work in conjunction with land-based pump skids, submersibles, amphibious pumps and barges, among others, to improve efficiency and performance.

- Copes with high salt level in water and weeds in tailings etc.

If you are looking for:

- The best practice in managing tailings (TSF & RDA);

- Exceeding regulatory framework in environmental compliance by adopting innovative solutions;

- Improving efficiency, cost effectiveness and asset performance;

- Effectively managing dewatering with optimised value proposition;

- Reducing infrastructure costs while achieving the best solution, contact Rob Hair at robhair@rbhmechanical.com.au or email manager@rbhmechanical.com.au

Rob Hair, an inventor and MD of Turret™ Engineering, has over 35 years of experience in dewatering solutions for the mining and resources sector. Having established a successful dewatering business, Rob has gained significant industry experience and continues to work with tailings engineers, design engineers, end users, pump companies, project managers and stakeholders to deliver reliable and innovative solutions to the industry. Having callouts to rescue submerged pumps, replace cavitated impellers and solve decant challenges, Rob has forged a theoretical idea into a practical and innovative solution.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation