Sintech

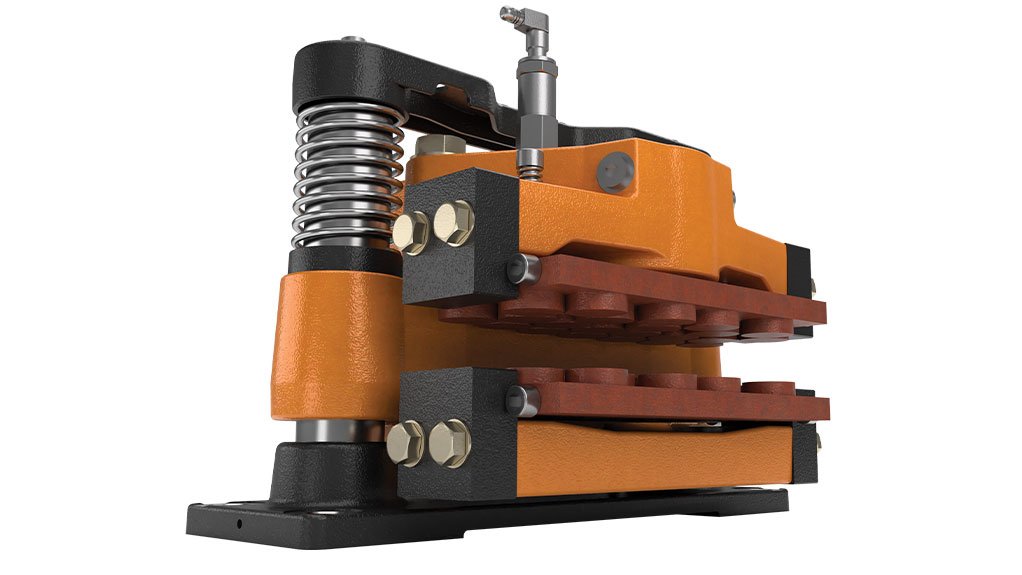

Since 1989, Svendborg Brakes has been recognised as a leading global expert in intelligent braking solutions for many applications across a broad spectrum of industry. Extensive application knowledge, innovative design, fast prototyping and exhaustive testing ensures that customers get the most technically advanced, most durable and safest braking systems to meet their specific requirements.

Nowhere is this more relevant than their investment in the wind turbine industry.

Svendborg is a small fishing town in Denmark and while they have several manufacturing facilities around the world, this is their design centre but, more significantly, the site of their research and development. No expense has been spared on dynamometers to test the brakes and brake components as well as a full size turbine set up to test for temperature stability under both extremes of hot and cold and a salt chamber test specifically for offshore turbine installations. The attention to detail extends to a specialist unit developing modern “green” friction materials for use in the brakes.

There are several braking opportunities on a turbine depending on the particular original equipment (OE) design. Svendborg have over the years worked with every major OE manufacturer and are proud to offer a complete solution from high speed brakes, low speed brakes, yaw brakes, locking devices and hydraulic power units.

Their South African partner Sintech offers the same commitment to service and support of each of these products throughout South Africa and the neighbouring countries from its base in Boksburg, which houses the main warehouse, modern rebuilding facility, sales support and field service.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation