Smart water use sets bottled sector apart

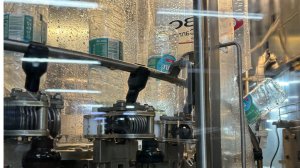

ROUTINE MAINTENANCE By keeping machinery in top condition, plants avoid the inefficiencies that often accompany ageing valves, hoses, or fillers, says the SANBWA

As South Africa grapples with mounting water insecurity, industries are under growing pressure to use water more efficiently. One sector that has made significant strides is the bottled water industry.

South African National Bottled Water Association (SANBWA) CEO Charlotte Metcalf explains that all its members are working to ensure that every drop is used wisely, and as little as possible is wasted, employing advanced technologies, strict self-regulation and sustainable practices.

While bottled water often draws criticism for commodifying a scarce resource, Metcalf says SANBWA members operate under some of the most rigorous water-use requirements.

“SANBWA’s membership criteria require full legal compliance with the National Water Act. All members must obtain valid water-use licences or general authorisations from the Department of Water and Sanitation (DWS) before any abstraction occurs.”

However, what happens after the water is extracted reveals the industry’s commitment to minimising waste, she adds.

The association has set a benchmark water-use ratio of 1.6 ℓ of water per litre of bottled product, a figure that includes water used for cleaning, production processes and bottling.

By contrast, many food and beverage sectors in South Africa use between 2.5 ℓ and 4 ℓ of water per litre of product.

“This figure isn’t just a target, it’s a ceiling,” says Metcalf, adding that “our members are constantly striving to do better”.

To achieve this, SANBWA members use a range of innovative technologies. One of the most effective is precision filling, which ensures that bottles are filled accurately, with minimal overfill and reject volumes.

When a bottle is rejected for quality-control reasons, the water it contains often cannot be reused; therefore, reducing reject rates is critical to saving water.

Metcalf says many bottled water plants have also adopted closed-loop systems, which allow for the water used in one part of the process to be treated and recirculated. For example, rinse water from bottle cleaning is often redirected for use in landscaping or equipment washing.

Instead of using traditional water-heavy sterilisation methods, members are also turning to ultraviolet and ozone technologies, as these alternatives achieve the same sanitisation standards while using much less water than conventional flushing systems.

However, Metcalf notes technology alone is not enough. A key part of the SANBWA’s approach involves strict monitoring and maintenance protocols that help to detect inefficiencies or wastage early.

“Leaks, especially small, undetectable ones, can go unnoticed for months in older systems. That’s why several of our members have installed real-time water flow monitoring systems that flag irregularities immediately.”

Routine maintenance of bottling lines also helps to reduce unnecessary losses. By keeping machinery in top condition, plants avoid the inefficiencies that often accompany ageing valves, hoses or fillers.

Water-quality and usage data is submitted as part of SANBWA’s independent yearly audit process, which assesses whether members are operating within their licensed abstraction limits and water-saving measures are being followed.

Metcalf adds that some members “go beyond their factory gates” to ensure that abstracted water does not go to waste. For example, off-specification or surplus bottled water, which might not meet branding or labelling requirements, is donated to municipalities for non-potable use, such as road construction or sanitation during service outages.

Other SANBWA members are investing in systems that align with the broader circular economy vision for water. Rainwater harvesting for landscaping is increasingly common at bottling sites, as are greywater reuse systems for cleaning and irrigation.

These measures not only reduce operational water use but also demonstrate that the private sector can contribute meaningfully to South Africa’s water security goals, she says.

While public debate often casts bottled water as a luxury product in a water-scarce country, the SANBWA argues that its members set a standard for responsible water use. By investing in cutting-edge technologies, maintaining tight control over their processes and engaging in transparent audits, these companies show that efficient water use and commercial success are not mutually exclusive.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation