Solutions provider aims to enhance mining productivity more sustainably

Weir Group CEO Jon Stanton says the demand for a significant increase in global copper production requires a multifaceted approach

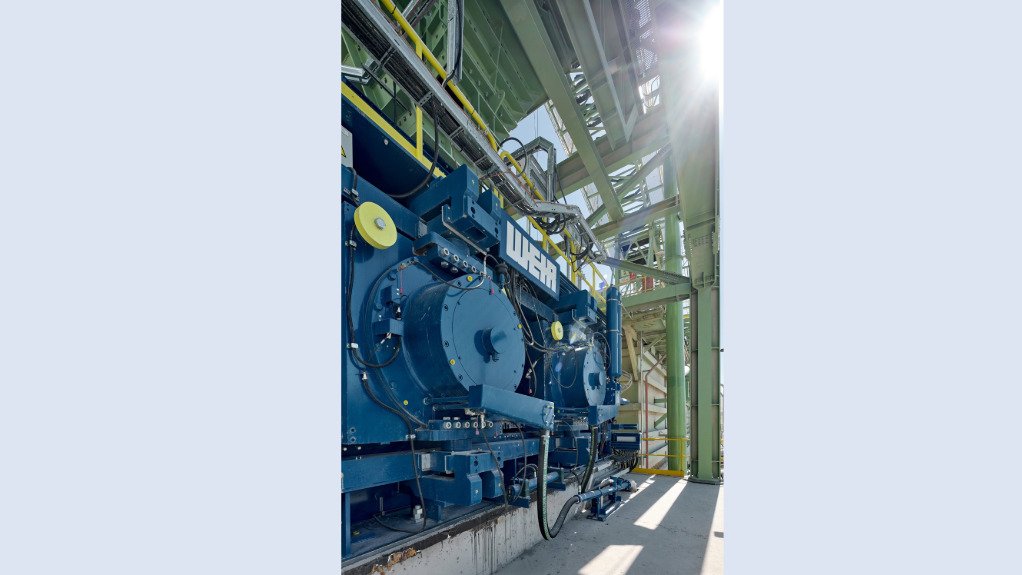

Weir’s new transformative technologies, such as the Enduron® HPGR, are helping challenge and redefine existing flowsheets to enhance productivity and sustainability

Weir showcased its digital solutions that use data and artificial intelligence to optimise customers’ process capabilities and enhance productivity at the recent Mining Indaba

Global engineering solutions provider Weir aims to assist the mining industry to meet the surging global demand for critical minerals and metals in a more sustainable way. It aims to do this through improving existing mines to enhance productivity and expediting resource extraction.

Weir Group CEO Jon Stanton says the demand for a significant increase in global copper production requires a multifaceted approach.

“Identifying and developing new copper mines is crucial, alongside the expansion and improvement of existing mines to enhance productivity and expedite resource extraction. Furthermore, an emphasis on recycling becomes essential. This challenge extends beyond copper, encompassing other battery metals as well,” he says.

Traditional methods are no longer viable, he states. Sustainability measures are imperative, demanding processes that prioritise energy efficiency, reduce water consumption, and decrease waste generation.

Obtaining licenses for mine expansion relies on meeting increased environmental standards, emphasising the need for the industry to embrace sustainable practices.

“This transformative journey mandates the adoption of cutting-edge technologies and innovations, which is precisely where Weir aims to contribute with its engineering and technological expertise,” Stanton noted during an interview with Mining Weekly at the Investing in African Mining Indaba, in Cape Town, earlier this month.

Weir’s presence in nearly every major mine globally uniquely positions itself to address these challenges.

“The crucial role that technology plays in this transformation emphasises the need for innovative solutions to drive sustainability,” he highlights.

To this end, Weir is redirecting its focus on research and development to bring about new technologies that optimise energy and water consumption.

Stanton highlights that Weir, traditionally seen as an engineering firm, is adapting to the changing landscape by incorporating these new technologies into its solutions. The company aims to not only deliver efficient processing technology but also to make the equipment smarter through the integration of artificial intelligence.

He refers to this as "positive disruption in the digital age," acknowledging that the mining industry historically tended to lack innovation. He stresses the need for the industry to take risks and swiftly adopt new technologies to meet the escalating demand.

As the conversation shifts towards increasing output, Stanton highlights the importance of embracing new technologies and recycling mined materials. “The economic and sustainability benefits of developing equipment that uses less energy and consumes less water cannot be underestimated,” he says.

Further, technology plays a significant role in reducing global carbon dioxide emissions within the mining sector. Stanton reveals that about 3% of the world's electricity is used in crushing and grinding activities, highlighting how much energy is consumed by mining processes.

“We need an increased focus on ongoing efforts to move towards renewables and, simultaneously, make mining equipment more energy-efficient,” he states.

Stanton also mentions the increasing use of digital tools in mining for enhanced productivity, emphasising the potential of an integrated approach to technology implementation, which combines big data and artificial intelligence to improve the entire mining process.

Meanwhile, Stanton reveals that Weir is working on several initiatives to develop closed-loop water systems through innovative technologies to address the critical issue of water scarcity.

“Mines face challenges whether they are located in water-scarce or water-abundant regions and Weir offers strategies that can minimise water use and maximise water recycling,” he explains.

He also notes that engagement with local communities is a crucial factor in driving positive change in mining practices, emphasising the need for sophisticated stakeholder management.

“We need to recognise the diversity of interests within local communities and that collaborative efforts with these communities are essential for securing social licenses to operate,” he says.

Finally, he points out the importance of talent recruitment and retention in the mining and metals sector.

“It is important to align our company missions with the broader goal of sustainable and efficient resource delivery. We need to attract the best talent by presenting mining as a key player in the global shift towards a metals-based economy,” he states.

“Weir's commitment to sustainable mining practices and innovative technologies positions us as a key player in driving positive change in this essential sector,” Stanton concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation