TAKRAF Groups marks 300 years with renewed focus on sustainable mining solutions

Creamer Media publishing editor Martin Creamer interviews TAKRAF South Africa MD Richard Späth about the group’s deep roots and forward-looking strategy

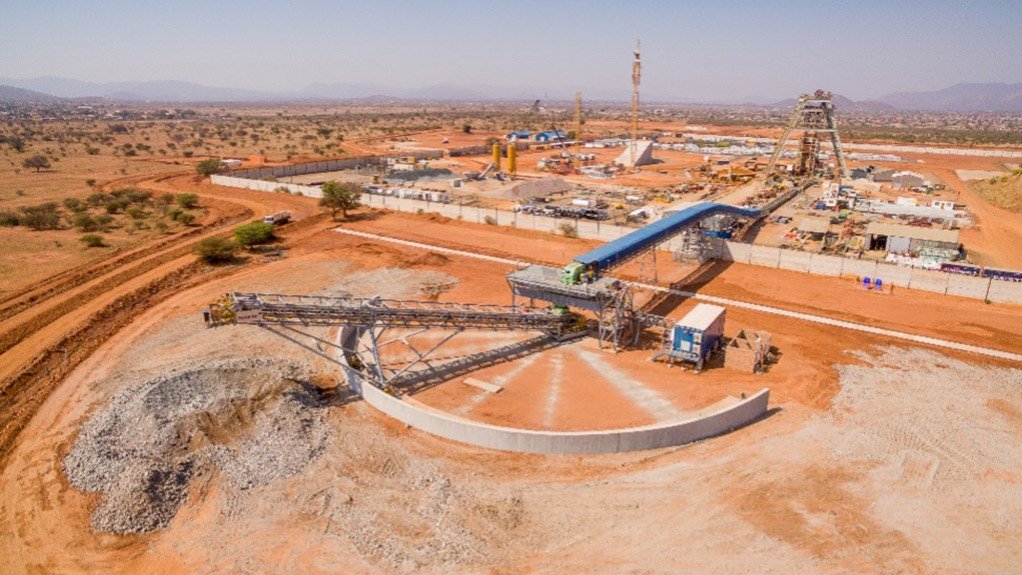

THINKING LONG-TERM Overland conveyors offer significant environmental benefits compared with trucking or yellow equipment, yet they are underused owing to the initial cost considerations

LESS WATER, LESS RISK Dry stacking is becoming increasingly critical, especially considering recent tailings dam failures globally

Global mining technology company TAKRAF Group, which celebrates an extraordinary 300 years of industrial history in August, is marking the milestone by reaffirming its commitment to innovation, sustainability and long-term partnership with mining clients across the globe.

In an exclusive interview with Engineering News & Mining Weekly, TAKRAF South Africa MD Richard Späth highlights the Group’s deep roots and forward-looking strategy. Founded in August 1725, the company has evolved into a trusted provider of high-performance solutions in material handling, minerals processing and comminution, through its TAKRAF and DELKOR brands.

“TAKRAF Group is a group of people passionate about delivering solutions. We’ve developed a wide range of equipment through a dedication to innovation, but at the heart of it is our people’s commitment to delivering solutions to our clients,” says Späth.

Shifting Priorities

Known historically for building some of the largest mobile mining machines in the world, TAKRAF Group has observed a recent shift in the African market. Clients are increasingly opting for smaller-scale bulk material handling systems such as radial stackers rather than full stockyard installations.

“There’s a noticeable move toward lower upfront capital investment, even if it may not always align with environmental imperatives globally. Overland conveyors, for example, offer significant environmental benefits compared with trucking or yellow equipment, yet they are underused owing to the initial cost considerations,” Späth explains.

He believes that, in the long term, materials handling could provide neat environmental solutions for clients.

Enhancing Minerals Processing with Innovation

Through its brand DELKOR, TAKRAF Group continues to lead in liquid-solid separation technologies, including thickeners, filters and flotation cells. A major recent innovation is the MAXGen flotation mechanism, which delivers improved performance in platinum group metals operations.

“This new mechanism boosts the efficiency of our flotation cells, which are built on decades of proven Bateman BQR Flotation technology,” Späth notes.

He adds that the liquid/solid separation space dovetails with the overall TAKRAF Group offering, enabling the company to support a significant part of its clients’ flow sheet with material handling and minerals processing solutions. This is in addition to a product range focused on the comminution side of the flow sheet.

“We offer a sizer range and have also moved into the High-Pressure Grinding Roll (HPGR) space. In South Africa, specifically, we have also been supplying Bradford rotary coal breakers, which are under licence from turnkey crushing and separating systems supplier TerraSource Global.”

Tailings Safety and Sustainability

A growing area of concern is mine tailings management, with TAKRAF Group offering DryStack Tailings (DST) solutions that improve water recovery and safety.

Not only is it important environmentally to extract as much water as possible from tailings for recycling but so is ensuring human safety.

“Dry stacking is becoming increasingly critical, especially considering recent tailings dam failures globally. Yet, it's still often seen as a ‘grudge purchase’ by operators. We’re seeing progress, but there’s more work to be done,” Späth emphasises.

Deepening Local Support

To improve after-sales service and maintenance, TAKRAF South Africa has expanded its footprint beyond its Johannesburg office to include Mpumalanga to support coal mining and the Northern Cape to better support equipment at iron-ore and manganese operations.

“Three decades ago, clients managed their own maintenance. Today, they need partners, owing to a loss of skills. We stay engaged with clients post commissioning to ensure that maintenance is performed correctly, and the right components are used so that our equipment’s performance meets expectations,” he says.

As TAKRAF Group looks ahead, its leadership sees the company’s long-standing presence in South Africa – now more than 100 years – as a foundation for future growth.

“We’re committed to being in South Africa for another 300 years – delivering not just equipment, but full technological solutions to support the future of mining. Mining may come under pressure, but it remains vital – and so do the partners who help the industry operate responsibly and efficiently,” Späth advances.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation