Technology optimises mines’ rock fragmentation and operational efficiency

AXXIST delivers favourable outcomes from complex blasting

AXXIST Initiation System

Advanced blasting technologies, combined with specialised expertise and meticulous planning, are helping mines achieve new levels of productivity and efficiency.

Quality blasts that deliver optimal rock fragmentation are at the heart of this technology focus, according to BME's General Manager of Marketing and Technology, Nishen Hariparsad. In a recent project, the company’s AXXIS™ Product Support and Global Blasting Technical Services team collaborated with a mining customer to facilitate complex pit design changes, leading to significant improvements in operational efficiency.

“The project addressed limitations on excavation caused by a previous bench design philosophy,” explained Hariparsad. “Difficult geology in the lower 20m of the blast bench also contributed to poor fragmentation results, which further impeded performance.”

Increased productivity

By integrating production benches across multiple pits and increasing the blasted depth from 24m to 48m, the mine significantly reduced costs and cycle times. Faster overburden removal using excavators and haul trucks streamlined the overall extraction process.

“The mine has since reduced downtime due to inefficient blasting and achieved the desired fragmentation which, together with optimised load and haul operations, has increased overall productivity,” he said. The project did not come without challenges, however; he pointed to the need to maintain optimal fragmentation and blast performance when integrating the benches.

“A poor result could have resulted in a large area that would be difficult to excavate – which would require costly remediation," he explained.

Different blast style

To address these challenges, BME worked with the mine to adopt a different blast style, carefully considering the amount and use of explosive energy and how these would be impacted by initiation.

“Blast area size and rock response time were also important factors as these would ensure that adequate burden relief was introduced to facilitate blast movement and secondary fragmentation,” said Hariparsad.

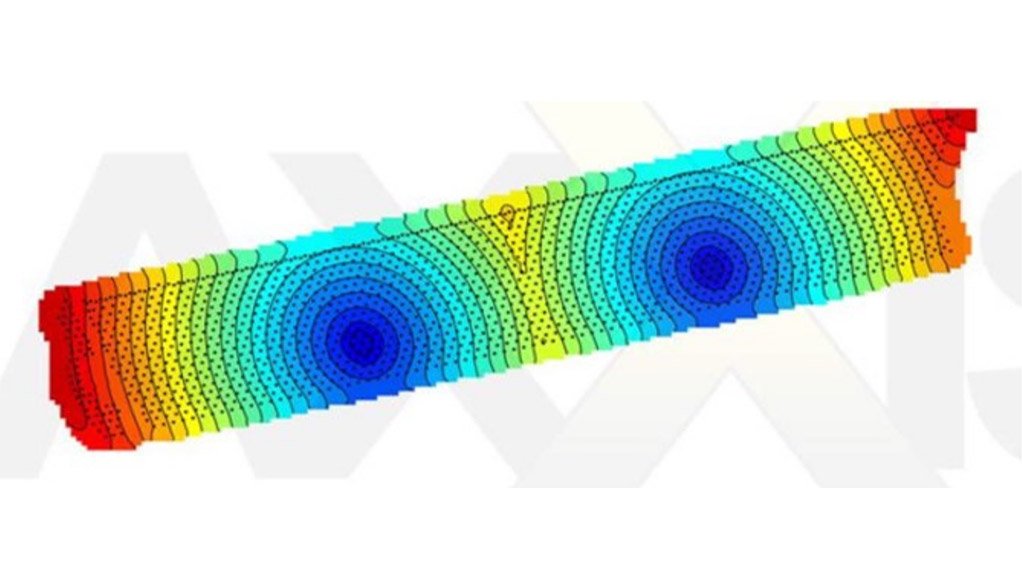

An innovative blast initiation sequence was designed to activate two central lift points within the blast zone, creating relief by incrementally increasing the timing from these points.

“Ensuring sufficient timing was of utmost importance to effectively blast rock so as to maintain the desired fragmentation,” he explained.

High accuracy

He highlighted that the AXXIS™ digital initiation system was critical to ensuring the high accuracy required to undertake the blast. Its flexibility enabled the calculated initiation timing to be programmed down to sub-millisecond accuracy, providing absolute control. The timing was designed in elliptical form to facilitate favourable surface movement under given conditions. He also emphasised the value of the company’s BLASTMAP™ software, which simulated the blast – enabling predictable outcomes before actual detonation.

“To ensure the correct blast design was implemented, the rock geology was assessed ahead of time, considering the explosive type, strength and loading for each hole,” he said. “The powder factor was adjusted around the central initiation points to ensure sufficient energy to create relief within the blast.”

The blast design achieved the desired fragmentation at deeper levels, which was previously a key concern. Based on the success of this blast, the mine has continued to use this method to merge benches and the new mining approach.

“This positive project outcome has enabled our customers to work towards achieving their goal of establishing a new benchmark for coal mining productivity and efficiency,” said Hariparsad. “This further showcased the value of technology in modern blasting systems.”

Moving emulsions underground

BME’s innovations extend beyond surface mining to underground operations, where they are also improving fragmentation and reducing mining costs. Derick Menezes, Regional Manager: Underground Operations at BME, highlighted that both extra fine and excessive forced rock fragmentation increase total mining costs.

“It is imperative to align fragmentation size and distribution with the capabilities of existing loading, hauling and processing equipment,” said Menezes.

He highlighted that explosives make up a substantial portion – between 5% and 15% – of total underground mining costs, so their impact needed to deliver maximum results.

“Technologies like AXXIS™ and BLASTMAP™ ensure that mines achieve the desired fragmentation size and distribution to allow improved diggability and footwall conditions – which in turn translate to reduced operating costs downstream. There is also less wear and tear on loading equipment, and less need for secondary drilling and scaling.

Safer ground

Ground conditions also benefit from precise blasting, making the mining environment safer through better stability of hanging walls and side walls.

“By reducing overbreak and underbreak, quality blasting improves safety conditions for employees and prevents the risk of damage to equipment,” he said.

Another benefit of blasting with BME technology such as AXXIS™ is reduced vibrations. This mitigates the impact of underground operations on nearby communities and the surrounding environment – a growing priority in mining’s ESG commitments. A key factor in achieving a quality blast is accurate blast initiation, according to Crivice Mahlaule, BME's Underground Operations Manager: Northern Cape.

“Technological advancements allow detonators to be programmed to fire at intervals as short as 1 millisecond, which gives blasters close control over each blast,” said Mahlaule. “This is especially important in areas where there is a high risk of seismic events.”

Reliable results

The intuitive logging and testing processes used by AXXIS™, as well as its fault-finding capabilities and post-blast analysis, also ensure that initiation and results are reliable and consistent.

He also highlights the innovations to transport emulsion explosives more efficiently and quickly from surface to underground, such as BME’s Rapid Downhole Delivery System. Trucks can offload emulsions into an underground storage area via a vertical gravity feed located at the surface. Once underground, there are systems for storage and refilling of Emulsion Charging Units (ECUs).

“ECUs and bags for charging stopes in narrow-reef areas are refilled at filling stations that are located close to working areas,” he said. “The refilling stations and the emulsion storage area are access controlled, as is the zone where the gassing agent is stored above ground.”

Pumpability

On-site trials undertaken by BME demonstrate the robustness of BME’s dual-salt emulsions in applications like this. Emulsions were off-loaded into the gravity feed and then repumped it to the surface again more than three times in a continuous cycle of about 945 m.

“Our dual-salt emulsions’ characteristics remained unchanged throughout the test, demonstrating their suitability to extreme handling conditions,” he said. He added that further tests demonstrated that BME’s emulsions could be pumped over distances of 1,000 m without any measurable change in their performance or physical conditions.

Mahlaule explained that the savings achieved with this delivery system varied depending on factors such as size and type of operation, circumstances and the form of explosives used.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation