Testwork confirms synthetic diamond manufacture potential from Blencowe’s project

The results of additional testwork have confirmed that graphite concentrates from London-listed Blencowe Resources’ Orom-Cross project, in Uganda, are suitable for the manufacture of synthetic industrial diamonds, which the company says further validates the quality, versatility and downstream optionality of its graphite feedstock.

The testwork was undertaken by American Energy Technology Co (AETC) in Chicago, in the US, and forms part of Blencowe’s value-addition programme focused on demonstrating commercially viable, non-China downstream applications for Orom-Cross graphite.

Notably, the testwork achieved a diamond conversion yield of 53.6% by weight, exceeding the typical industry benchmark of about 50%, Blencowe points out.

AETC notes that this threshold is widely regarded as critical in determining whether synthetic diamond production can be undertaken economically outside China, given the highly competitive cost structure of the industry.

Conversion yields below this level typically necessitate lower-cost Chinese processing to remain viable, it explains.

Production of industrial diamonds provides Orom-Cross with another significant value-adding enhancement opportunity beyond the sale of graphite as concentrates and Blencowe will be seeking offtake opportunities in this sector ahead as it continues to drive towards first production, the company indicates.

AETC further observed that many natural graphites, including several deposits across East Africa, are less suitable for synthetic diamond manufacture owing to thicker, less compressible flake structures, which inhibit efficient diamond formation.

In contrast, the fine, compressible flake characteristics of Orom-Cross graphite proved highly conducive to diamond synthesis, representing a distinctive quality signature of the deposit, it points out.

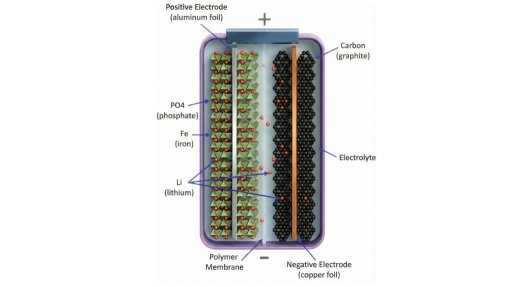

Synthetic diamond manufacture is a specialised, high-value industrial market where feedstock quality and conversion efficiency directly influence cost competitiveness. These results confirm that Orom-Cross graphite meets the technical thresholds required to support economically viable diamond production outside China, opening additional downstream pathways alongside the company’s core battery and energy transition strategy, Blencowe informs.

This optionality further differentiates Orom-Cross as a high-quality, non-China graphite source, aligned with increasing Western focus on secure supply chains, local processing and advanced manufacturing, it adds.

“Importantly, the confirmation of multiple high-value end markets strengthens the overall Orom-Cross development case and supports Blencowe’s ongoing funding and offtake processes. In parallel, the company continues to progress drilling and resource definition across the project, with remaining assay results from the Iyan and Beehive programmes expected to be reported progressively, building toward sequential Joint Ore Reserves Committee resource updates,” Blencowe highlights.

“This work highlights a fundamental characteristic of Orom-Cross graphite: its quality extends beyond battery applications into demanding industrial uses where conversion efficiency and cost competitiveness are critical. Achieving mono-crystalline diamond formation at conversion yields above industry benchmarks reflects the compressibility and structural integrity of our graphite, which continues to differentiate the project,” Blencowe executive chairperson Cameron Pearce says.

“As further drill results and technical validation are delivered, Orom-Cross continues to mature as a scalable, high-quality graphite development. This progress strengthens the underlying project fundamentals and is directly supporting funding and offtake discussions currently underway, as we advance toward the next resource update,” he adds.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation