The end of flats in underground mining starts with TyrFil

Mining is one of the toughest industries on Earth, especially below the surface, where equipment must perform in confined tunnels, over jagged rock, and through unpredictable conditions that test both machine and operator endurance. Every decision in this environment matters, from safety protocols to technology adoption. One decision that continues to reshape underground mining operations is how to deal with one of the most costly and disruptive challenges: flat tyres.

For decades, flat tyres have been a hidden drain on mining productivity. They halt production, create safety hazards, and inflate maintenance budgets. But today, mines across the globe are proving there is a smarter way forward—with TyrFil, the original polyurethane flatproofing solution that eliminates flats altogether while boosting safety, sustainability and bottom-line performance.

High Cost of Downtime

Mining runs on tight schedules and tighter margins. When a loader, shuttle car, or underground haul truck goes down owing to a flat tyre, the ripple effects are immediate and expensive.

- Direct costs: A single hour of equipment downtime can cost thousands of dollars in lost productivity. Multiply that by several flats a month and the numbers quickly escalate.

- Safety concerns: Emergency tyre repairs underground often require moving equipment out of narrow tunnels, halting nearby operations, and bringing in specialised crews, exposing workers to unnecessary risk.

- Project delays: Even a small disruption can throw off timelines, creating bottlenecks across the operation.

For many mines, flat tyres are not just an inconvenience, they are a recurring operational threat.

Why Pneumatic Tyres Fall Short

Air-filled pneumatic tyres are familiar and flexible, but they are not built for hostile underground conditions. They are puncture-prone, as sharp rock fragments, metal debris, and uneven surfaces can easily tear through tyre casings. Maintenance is also difficult, since keeping consistent pressure underground is challenging, and pressure variations not only increase the risk of flats but also compromise handling. In addition, tyre replacements create logistical headaches in tight mine shafts, consuming hours of valuable production time. The reality is that pneumatic tyres cannot keep up with the pace and pressure of modern mining.

TyrFil Flatproofing Works Underground

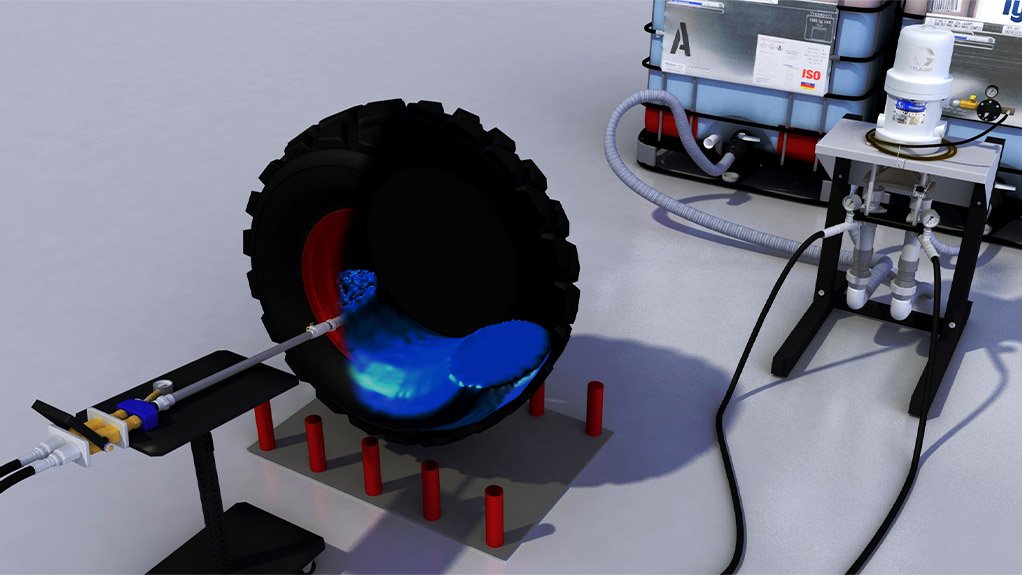

TyrFil flatproofing solves this problem at the source. Instead of air, tyres are filled with a polyurethane liquid that cures into a resilient elastomer core. Once filled, the tyre becomes completely flatproof, impervious to punctures, blowouts, or underinflation.

This technology has been trusted in underground mining for more than five decades. Mines that adopt TyrFil do not simply eliminate flats; they also unlock a host of operational advantages. They experience zero flats and therefore zero downtime from tyre failures. They benefit from consistent pressure and stability, even in harsh environments. Tyres and equipment last longer thanks to shock absorption and vibration reduction. Operators also enjoy improved comfort and safety, with less bounce and smoother control.

Safety and Operator Well-Being

Mining is not only tough on equipment, it is tough on people. Operators often work long shifts in low-light, high-stress environments where fatigue is a constant challenge.

TyrFil helps by minimising jolts and vibration, creating a smoother ride that reduces musculoskeletal strain and operator fatigue. Equipment filled with TyrFil also delivers better stability, giving operators more control in confined tunnels. That means fewer risks, better comfort, and stronger performance from crews who need every advantage underground.

Protecting Equipment Investment

Mining equipment is a significant capital investment, and unplanned repairs are costly. Beyond tyres, components like axles, suspensions and hydraulics suffer from repeated shock when machines hit debris or operate on uneven surfaces.

By cushioning impacts, TyrFil reduces stress across the vehicle, extending component life and reducing repair costs. In underground settings, where moving machines in and out for service is difficult and expensive, this protection is invaluable.

Switching to TyrFil is more than a preventative step; it is a strategic investment. Mines that adopt flatproofing see measurable returns almost immediately. They lower maintenance costs by avoiding emergency tyre replacements. They increase uptime with fewer disruptions and smoother operations. Tyre budgets become more predictable, with fewer surprise expenses. Tyre life is extended, as filled tyres resist punctures, blowouts, and heat-related damage that would otherwise shorten their service. Equipment strain is also reduced thanks to TyrFil’s cushioning effect, which lowers the repair frequency for suspensions, axles, and frames. In addition, worker safety is improved by removing the risk of sudden flats in demanding underground or surface mining conditions.

A Smarter, Sustainable Solution

Modern mining is not only about extraction, it is about efficiency, safety and sustainability. TyrFil supports all three.

As environmental regulations tighten, mines must find ways to reduce waste and improve ecological footprints. TyrFil enhances sustainability through its closed-loop recycling technology. Once cured, TyrFil can be reclaimed and processed through Carlisle’s recycling systems, allowing previously used fill material to be blended with virgin tyre fill. This innovation reduces the need for petrochemicals, lowers overall carbon footprint, and prevents cured polyurethane waste from ending up in landfills. This delivers both environmental and cost-saving advantages for mining operations without sacrificing performance.

Carlisle TyrFil invented polyurethane tyre fill over 50 years ago and remains the global leader today, holding the most original equipment manufacturer approvals in the industry. With multiple durometer options available, TyrFil can be tailored to fit a wide range of mining equipment, from loaders and haul trucks to utility vehicles and drill rigs. Its team of global experts supports mines with technical service, training, and a reliable supply chain spanning multiple manufacturing sites across the US, Germany and China. Wherever mines operate, TyrFil keeps them rolling.

Underground mining demands reliability, and flat tyres have no place in that future. By eliminating flats, improving safety, protecting equipment, and advancing sustainability goals, TyrFil empowers mining operations to focus on what matters most: productivity, profitability and people.

Because in mining, every minute counts. And with TyrFil, every minute keeps moving forward.

Keep mining with TyrFil. Learn more at CarlisleTyrFil.com

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation