Titanium beneficiation complex, South Africa – update

Photo by Nyanza Light Metals

Name of the Project

Titanium beneficiation complex.

Location

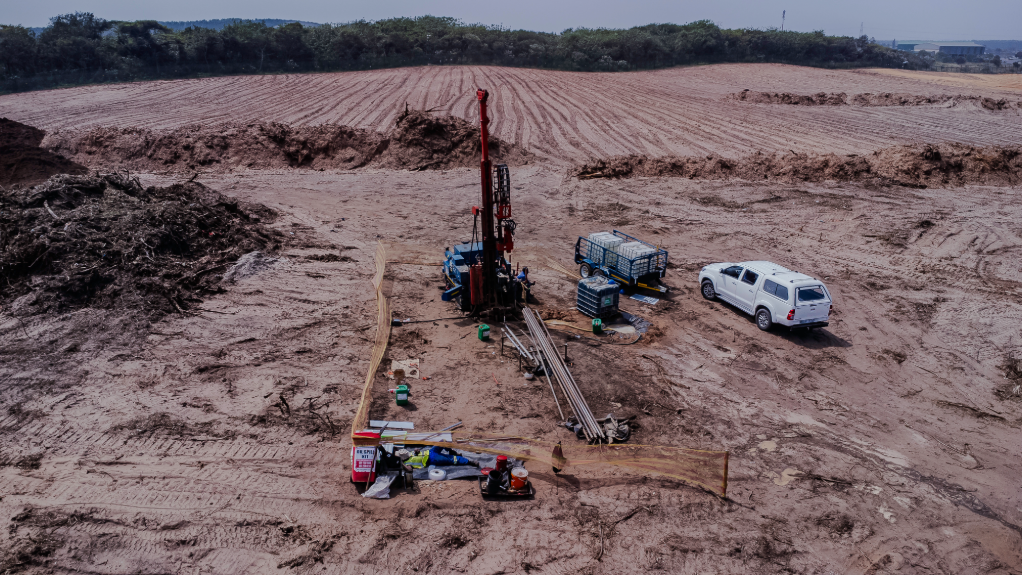

The Richards Bay Industrial Development Zone (RBIDZ) Phase 1F, in KwaZulu-Natal, South Africa.

Project Owner/s

Titanium dioxide pigment manufacturer Nyanza Light Metals, in partnership with the RBIDZ. Arkein Industrial Holdings is the founding shareholder of Nyanza, with 70%, while DBF Capital holds the remaining 30%.

Africa Finance Corporation, African Export-Import Bank, the Industrial Development Corporation, and the Department of Trade, Industry and Competition are co-development partners.

Project Description

The project entails the construction of a titanium beneficiation facility for the manufacturing of titanium pigment, a sulphuric acid plant with an 8 MW co-generation power plant and other utility plants.

The project will produce about 80 000 t/y of titanium dioxide pigment at peak production, of which 15% will be sold locally, and the balance of up to 85% will be exported.

The project will be built in phases.

Phase 1 involves the construction of a product testing and development centre, which will be able to produce 700 t/y of titanium dioxide pigment, mainly for customer and market development activities.

Phase 2 entails the construction of the main plant. The plant will use 300 000 t/y of sulphuric acid and 200 000 t/y of sulphate ilmenite to produce 80 000 t/y of the titanium dioxide pigment, targeting mainly the paints, industrial coatings and plastics manufacturing markets.

Potential Job Creation

During construction, the project will create more than 3 000 jobs. A further 850 permanent jobs will be created once the project is operational.

Already commissioned is a R200-million product testing and development centre that will be used to train more than 200 young graduates, operators and artisans who will eventually be transferred to the main plant.

Net Present Value/Internal Rate of Return

Not stated.

Capital Expenditure

Capital expenditure, excluding financing and working capital costs, is estimated at $550-million (R9.5-billion). Peak funding is estimated at $860-million.

Enterprise value is estimated at $1.1-billion (R19-billion).

Planned Start/End Date

Production from the main plant is set to ramp up from 2027.

Latest Developments

The African Development Bank (AfDB) has approved financing of $75-million for Nyanza Light Metals to support the development, construction and operation of the manufacturing plant.

The AfDB funding package includes $25-million from the Africa Growing Together Fund. This is a joint initiative of the AfDB and the People’s Bank of China. The AfDB package is part of a syndicated financing package that has been arranged by the Africa Finance Corporation and the African Export-Import Bank, acting as the initial mandated lead arrangers and bookrunners.

Key Contracts, Suppliers and Consultants

East China Engineering Science and Technology (engineering, procurement and construction).

Contact Details for Project Information

Nyanza Light Metals, tel +27 11 684 1286 or email info@nyanzametals.com.

Article Enquiry

Email Article

Save Article

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation