Tyre solution gains traction in Zim mines

DURABLE TYRE CORE The durable polyurethane elastomer employed to replace the air in tyres cures into a flexible, shock-absorbing elastomer core

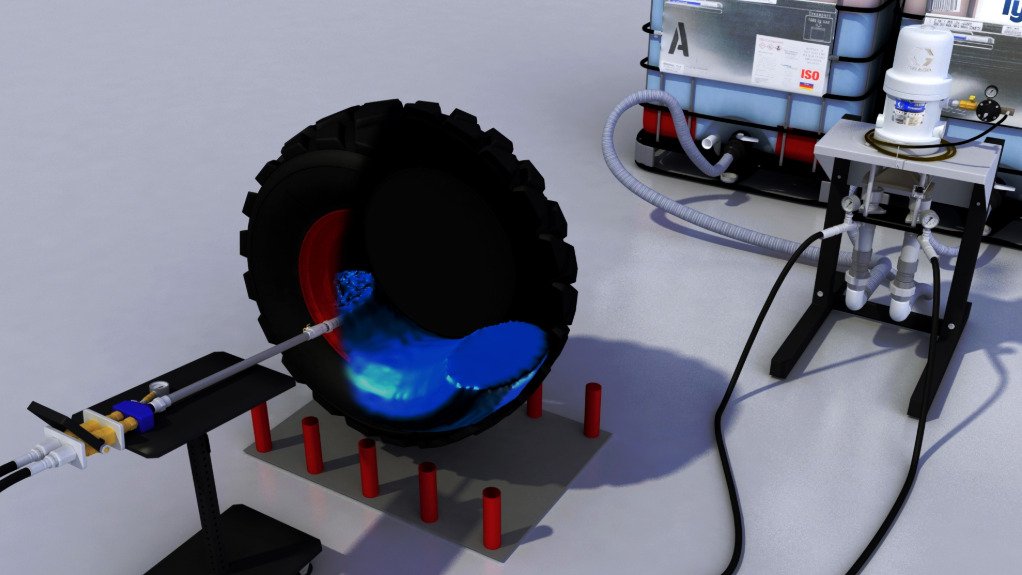

HOMOGENOUS MIXTURE The recycling technology’s computer systems measure and mix controlled amounts of virgin liquid tyre fill and granulated tyre fill into a homogenous TyrFil mixture that fills a tyre’s core

The growing problem of sending big volumes of waste to landfill and general waste issues associated with used tyres is intended to be addressed through tyre filling solutions provider Carlisle TyrFil’s long-standing tyre filling and flatproofing solutions.

Through the flatproofing solution, which has been used in South Africa for over 40 years, the company is aligning itself with Zimbabwe’s focus on reducing environmental impact as well as meeting stricter environmental enforcement by building a local dealer network with its local service partner.

This will play a vital role in introducing TyrFil to Zimbabwe’s mining operations, helping to prevent delays in production, according to Carlisle TyrFil business manager for Africa Walter Roux.

TyrFil’s flatproofing technology is especially valuable in this context, as mines invest in more advanced machinery, move towards mobile trackless machinery and extend operations, including processing facilities.

Flat tyres not only slow down operations but can also bring an entire operation to a halt, adds Roux.

The durable polyurethane (PU) elastomer is designed to replace all the air in off-road pneumatic tyres of mining vehicles, curing into a flexible, shock-absorbing elastomer core that is not only “durable but also eco-friendly”. This will increase uptime and ensure that projects stay on track, he adds.

Tyres that use this core can be recycled and repurposed, reducing the environmental impact of tyre disposal.

“We recycle our [flatproofing] product back into the tyre, which means that we have a recycling capability that reduces petrochemical use by up to 65%.”

To get Carlisle TyrFil’s flatproofing into the tyre, the company’s patented AutoFil-GenII pump can mix virgin tyre fill with PU grind, or both rubber crumb and PU grind, while delivering enhanced pump and grind speeds and significantly reducing clean-up time.

The recycling technology’s computer systems have been field-proven for more than a decade to measure and mix controlled amounts of virgin liquid tyre fill and granulated tyre fill into a homogenous Tyrfil mixture that fills the tyre in the same way as virgin liquid tyre fill, Roux explains.

In addition, the company’s Green Machine – which uses up to 65% of reclaimed tyre filling – aims to reduce the carbon footprint of Carlisle TyrFil’s customers while also saving on costs.

In addition, the AutoFil recycler pump system has made it possible to keep more than 68-million kilogrammes of tyre fill out of landfills every year since 2002, and is a tyre filling system that can recycle and reuse post-consumer oil-based tyre fill.

This system employs a one-step process to increase efficiencies and requires little labour, making it easy to operate by a single person, with clean-up only taking up to five minutes, says Roux.

Expanding Network

When considering mines in remote areas of Zimbabwe, often with limited infrastructure, Roux says that TyrFil can enable mining operations to replace or repair fewer tyres by making their current tyres last longer.

Introducing TyrFil into their operations will increase tyre life as the tyre stays at the optimal pressure for its life span. In some instances, tyre performance is increased two to three times. The need for pressure checks is reduced and machine availability increases.

Roux notes that TyrFil also makes a vehicle “a lot more stable”, which results in operators having more control over the vehicle.

Here, TyrFil cushions the ride of a vehicle, providing operators with a smoother experience that reduces fatigue and enhances their ability to work efficiently and safely compared to solid aperture tyres.

“It especially works well underground, as it replaces the air in the tyre, meaning that you don’t have a pressure vessel underground . . . you now have a vehicle that’s even more safe than it was before using the product,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation