Underground opportunities emerge as open pits mature

Safety is at the core of Murray & Roberts Cementation’s extensive range of training interventions in shaft sinking and trackless mining

Nurturing a culture of safety has reaped rewards for Murray & Roberts Cementation

The value of Murray & Roberts Cementation’s experience cannot be overstated and plays a vital role in successful project completion

In complex shaft sinking and mine development projects, Murray & Roberts Cementation adds value well beyond execution stage

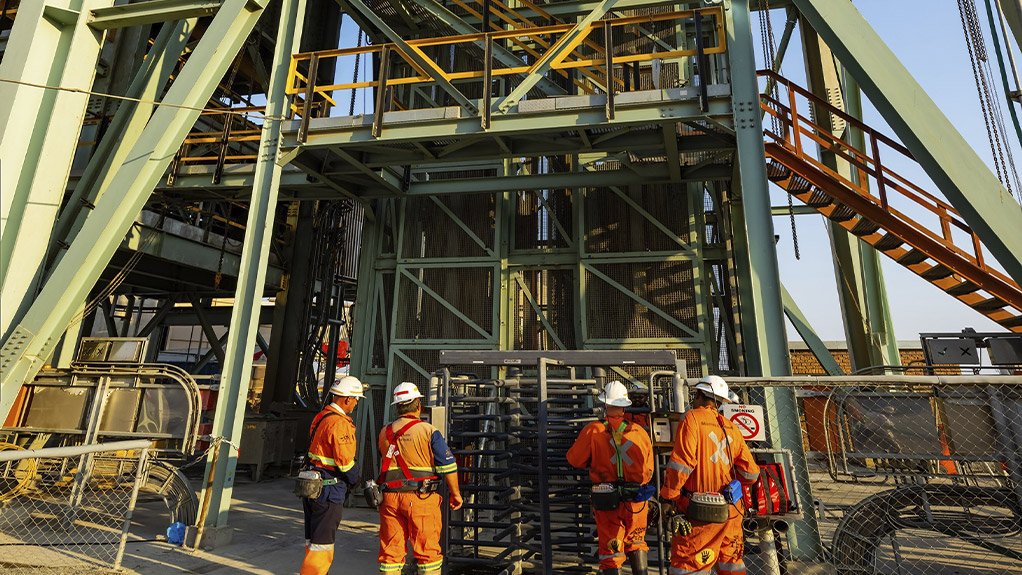

Murray & Roberts Cementation sets the benchmark in shaft sinking, combining world class expertise, advanced technologies and an unwavering commitment to safety

Murray & Roberts Cementation delivers tailored solutions for mining projects driving efficiency and innovation without sacrificing on safety

This article has been supplied.

With many open pit mines in Southern Africa reaching maturity, the scope for underground mining promises to create new opportunities for shaft sinking and underground mining specialists.

As a leader in this field for many years, Murray & Roberts Cementation has been busy with complex and long term projects, reinforcing its safety performance and honing its innovative practices and technologies. According to Japie du Plessis, Managing Director of Murray & Roberts Cementation, the current market looks full of potential.

“Among our differentiators has always been our depth of expertise and experience, with many of our people having served up to 35 to 40 years with us,” says du Plessis. “But what makes us most proud in recent years is how we have continued to pioneer safe execution in a field which is known for its risks and hazards.”

The company, recognised in 2024 by the Association of Mine Managers South Africa (AMMSA) with a safety award for achieving seven million fatality free shifts, reached another benchmark milestone in January 2025 when it achieved eight million fatality free shifts over a period during which it sunk numerous shafts for mining companies in Southern Africa. Underpinning this safety record is a substantial and ongoing investment in skills, he notes, driven by the Murray & Roberts Training Academy at Bentley Park near Carletonville.

“Safety is at the core of our extensive range of training interventions in shaft sinking and trackless mining,” he explains. “Our blended learning methodologies – and particularly our mock-up facilities – are recognised as benchmarks for the industry; many mines visit Bentley Park to learn from what we have developed.”

He highlights the way the company has engineered safety into all its processes, systems and equipment – based on a thorough analysis of past incidents. This has allowed the safe deployment of innovative shaft sinking methods and spurs on continuous improvement in designs and methodologies.

“Each project brings its own challenges and working conditions, so we apply our tailored approach to the specific needs of the customer,” says du Plessis. “This could include solving construction challenges underground, developing appropriate mining methods for underground crusher chambers or finding solutions for hoisting.”

Among its recent projects was the innovative adaptation of a ventilation shaft to include hoisting infrastructure that would operate where air is required to move at high velocities. There have also been shaft sinking contracts – including a recent 1,200 metre shaft – where conventional methods failed to deliver results due to the poor quality of ground conditions.

“We applied accepted sinking methodologies in creative ways to deal with those difficult ground conditions,” he says. “In the same way, we tailor solutions in trackless mining, pumping, hoisting, high pressure plug construction, dewatering, ore pass rehabilitation and drilling and blasting practice.”

The skills development capabilities in Murray & Roberts Cementation adds a vital sustainability element to its contract mining work which has recently included numerous projects in platinum and coal. The training and knowledge sharing with customers’ people lays the necessary groundwork for in-house mining to continue productively after handover.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation