UP showcases mining technology offering

The centre provides a 3D widescreen cinematic theatre, where active 3D visuals of typical mine designs, layouts and plans can be projected to students

Photo by Creamer Media's Tasneem Bulbulia

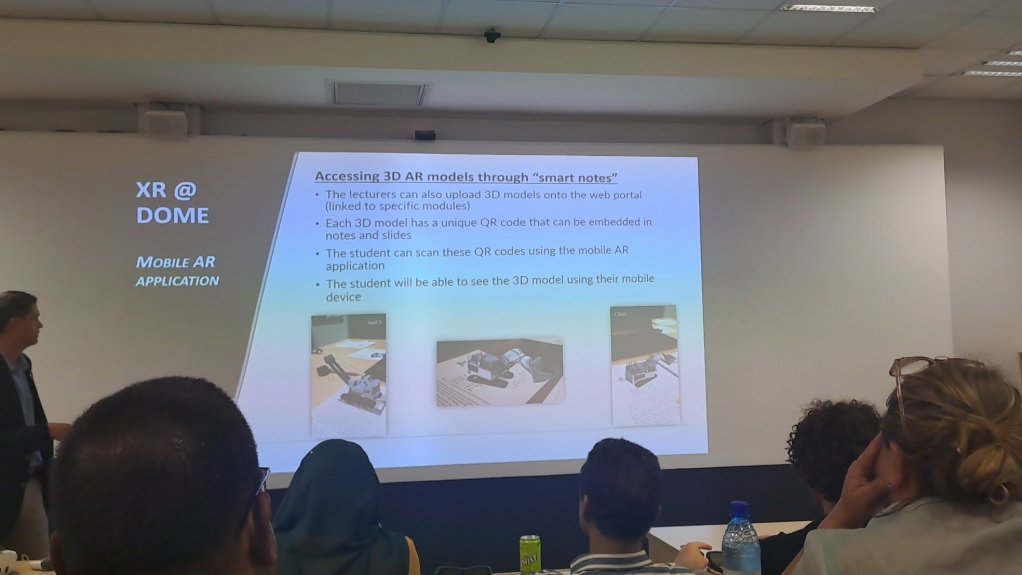

Senior lecturer Jannie Maritz showcases the mobile AR option

Photo by Creamer Media's Tasneem Bulbulia

The University of Pretoria’s Faculty of Engineering, Built Environment and Information Technology on March 13 hosted a media tour to demonstrate its Kumba Mining Virtual Reality Centre, highlighting the benefits of virtual reality (VR) and augmented reality (AR) in mining research and education.

Located at the university’s Hatfield Campus, in Pretoria, the centre caters to the Mining Engineering Department, which hosts about 128 students from first to final year.

The centre entails, firstly, a mining engineering lecture hall, which seats about 75 students.

It provides a 3D widescreen cinematic theatre, where active 3D visuals of typical mine designs, layouts and plans can be projected to students.

The centre also constitutes a 3D360 cave, or cylinder, providing a range of extended reality offerings.

This 10-m-diameter cylinder has a 360° 3D display, providing an immersive theatre experience for students, showcasing content such as mining methods, metallurgical or beneficiation plants, and rehabilitation plans.

The cylinder’s content models include geological hazard identification, where students are taught about geotechnical hazards underground without having to actually be on site, with a tethered VR application that uses the VR headset and a powerful computer.

Another model is checklist training, whereby students can explore mining vehicles in VR, and complete the checklist.

There is also an interactive blast wall model, which teaches marking and timing of a blasting process.

The centre also offers a mobile AR option, with students able to access 3D AR models though “smart notes”.

Lecturers can also upload 3D models onto the Web portable (linked to specific modules). Each 3D model has a unique QR code that can be embedded in the notes and slides. Students can scan these codes using the mobile AR application, and are able to see the 3D model using their mobile device.

Speaking to Mining Weekly, Mining Engineering Department senior lecturer Jannie Maritz explained that the centre allowed for mining engineering students to be exposed to dangerous environments, demonstrating it to them prior to an in-person site visit.

Moreover, lecturers are able to talk them through the hazards and operations of a mine in a safe environment, so that they are aware of what to look for and avoid when undertaking site visits.

The centre was launched in 2015, with initial sponsorship from miner Kumba Iron Ore.

Other major mining companies had since partnered in terms of research chairs, developments and project, Maritz said.

Since inauguration, several models had been developed for use. Contracted software developers developed some of this, while generalised content was also sourced from mining companies and adapted, he explained.

He added that VR headsets had improved considerably since the centre launched, and the department was now focusing on moving away from the static, non-scalable sets to scalable mobile sets.

Moreover, Maritz noted that the learnings from the centre had been rolled over to the health sciences faculty, which was now embarking on a drive to use XR in its departments.

However, the content developed for the screens was exclusive to the centre, and would require recalibration for use in other visual mediums; therefore, it is not scalable for other places, Maritz pointed out.

However, mobile headsets are more affordable and can also be moved, allowing them to be used to teach more people. The department has showcased this technology to students and mining companies at expos, which it highlighted as important for providing accessibility.

Maritz mentioned that students had to undergo VR orientation, learn how to use certain controls and were also taught in-app applications.

Moreover, from first to final year, the department offers a contingent of English lectures to ensure students are up to par, given that many speak it as a second language or are often unable to convey technical information properly.

“In teaching, the more senses you involve in your training, the better the retention will be. The centre adds an additional dimension to that. It will not replace the classroom environment, and it will not replace the real experimental training on site.

“Rather, this bridges the gap between the book knowledge and what's happening in the real mines,” Maritz averred.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation